Photovoltaic glass rim fire lance device

A photovoltaic glass and fire gun technology, which is applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of high flame intensity in the middle part, difficult adjustment of direction and angle, and small area for concentrated flame burning, and achieves increased Flame burning area, easy to observe, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

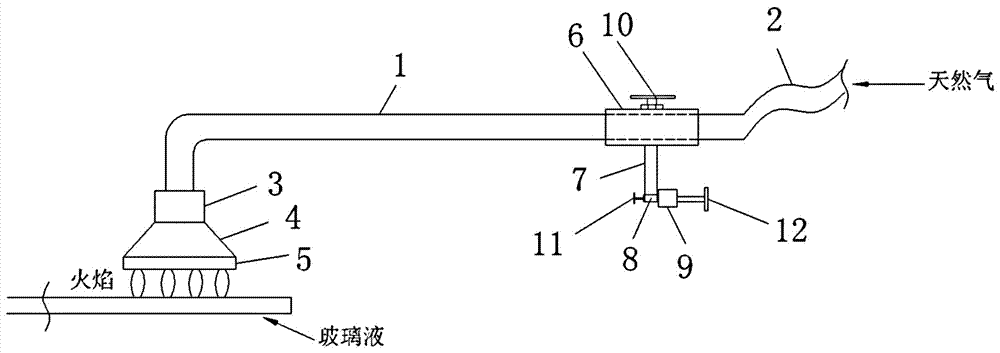

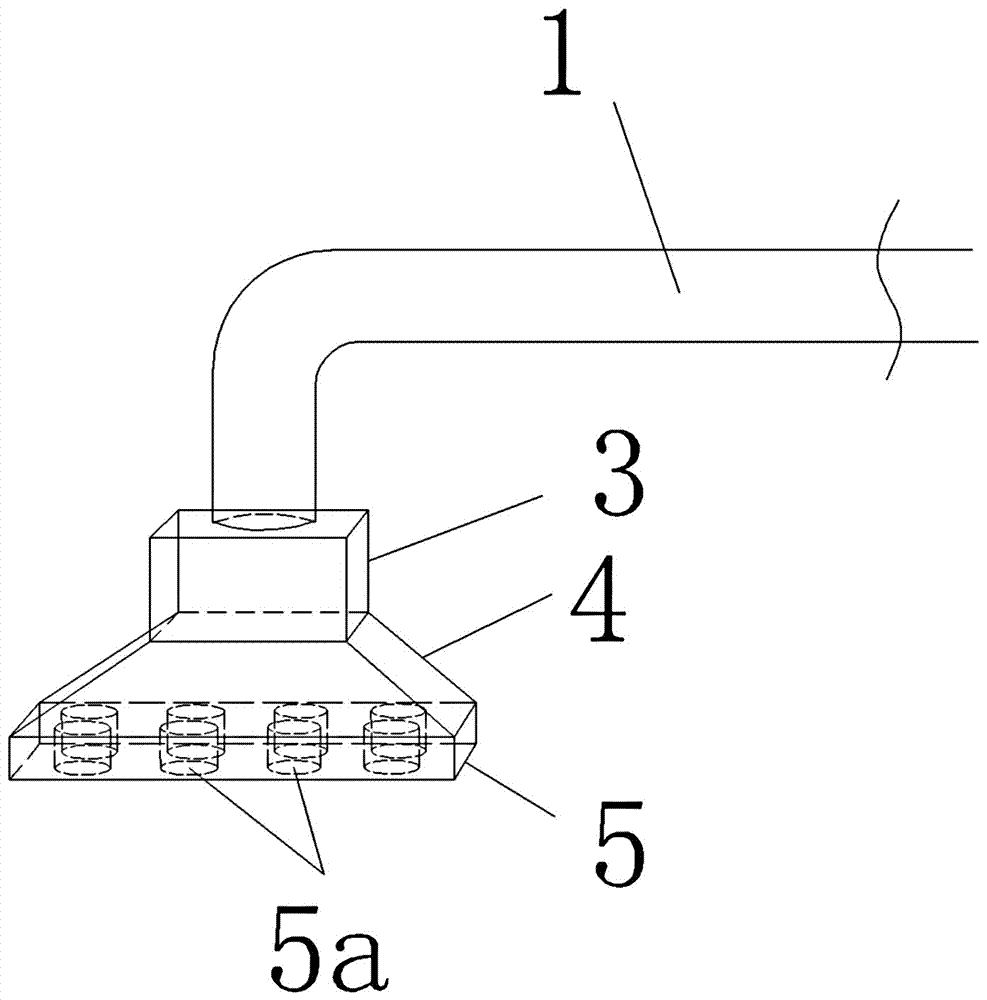

[0022] combine Figure 1~3 As shown, the present invention provides a photovoltaic glass edge gun device, comprising:

[0023] a. Combustion department,

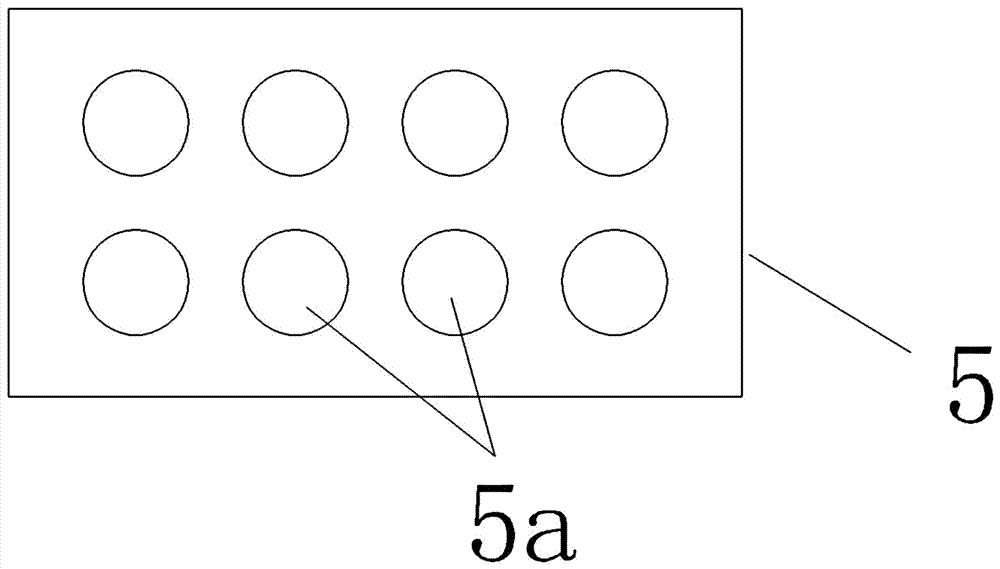

[0024] The combustion part includes an L-shaped gas pipe 1, the air inlet of the gas pipe 1 is connected with the natural gas input hose 2, the gas outlet of the gas pipe 1 is vertically downward facing the glass liquid, and the gas outlet of the gas pipe 1 is equipped with a gas diffuser Pipe sleeve 3, the other end of gas diffusion pipe sleeve 3 is connected with wide mouth mask 4, and wide mouth mask 4 is the funnel shape of upper narrow and lower width, and the wide mouth end of wide mouth mask 4 is provided with heating base plate 5, and a group of heating base plates are distributed on heating base plate 5. The combustion hole array 5a; the gas diffusion pipe sleeve 3 is preferably rectangular; the heating bottom plate 5 is made of refractory stainless steel, and the refractory temperature is ≥ 1250°C;

[0025] b. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com