Full-automatic efficient sewage and excrement treating and biogas generating device

A fully automatic, biogas-producing technology, applied in the field of sewage and livestock and poultry manure treatment, can solve problems such as increased equipment and energy consumption, reduced biogas yield, and inability to stir evenly, and achieves improved material and liquid quality, less heat loss, fermentation The effect of decomposition cycle and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

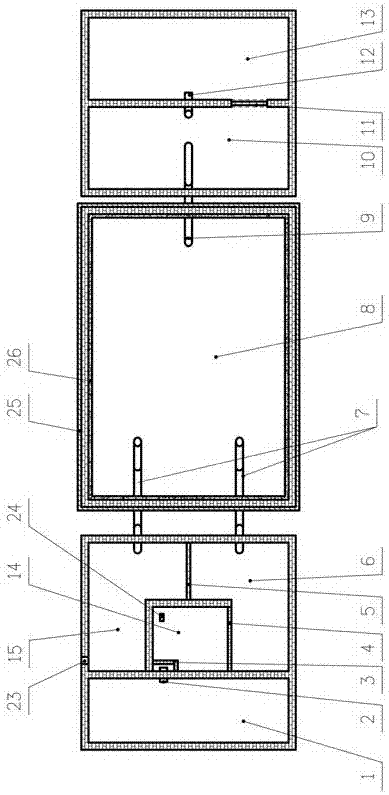

[0020] A fully automatic and efficient device for treating sewage and feces and producing biogas according to the present invention includes a U-shaped solid-liquid separation pond, a biogas pond, a biogas residue pond, a biogas slurry pond and a reclaimed water pond.

[0021]The solid-liquid separation tank of the present invention includes a coarse slag pool, a fine slag pool, and a membrane filtration tank. The coarse slag pool and the fine slag pool surround the membrane filtration tank in a U shape, and the coarse slag pool passes through the first channel The grid filter is connected with the fine slag tank, and the fine slag tank is connected with the membrane filter tank through the second grid filter, and the upper part of the membrane filter tank is provided with a suction pipe, and the membrane filter tank is connected with the reclaimed water tank through the suction pipe. Sewage and livestock manure first enter the coarse residue pond from the feed port of the coar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com