Environment-friendly PVC film and preparation method thereof

An environmentally friendly, high-quality technology, applied in the field of PVC film, can solve the problems of limited service life of PVC film, and achieve the effect of long service life, good stability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0021] A kind of environment-friendly PVC film of the present invention, according to mass ratio, comprises: PVC 85 parts, DOP 42 parts, calcium carbonate 3 parts, stabilizer 2.5 parts, soybean oil 6 parts, TiO 2 1 part and 0.3 parts of pigments, also including PVC mass fraction 0.6% graphene, 0.7% protein powder, 2.5% urea, 0.3% hydroxypropyl methylcellulose, 1.5% low-second nitrocellulose, 3.5% of catechins.

[0022] Graphene has super high surface hardness, when evenly distributed in PVC film, it can provide super high wear resistance on product surface.

[0023] Protein powder has air-moisture conductivity, which can give it the function of breathability and moisture absorption.

[0024] Urea has the functio...

PUM

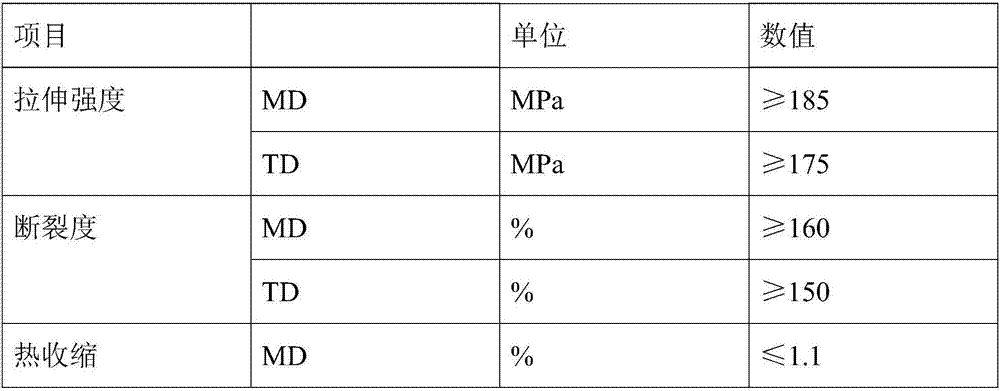

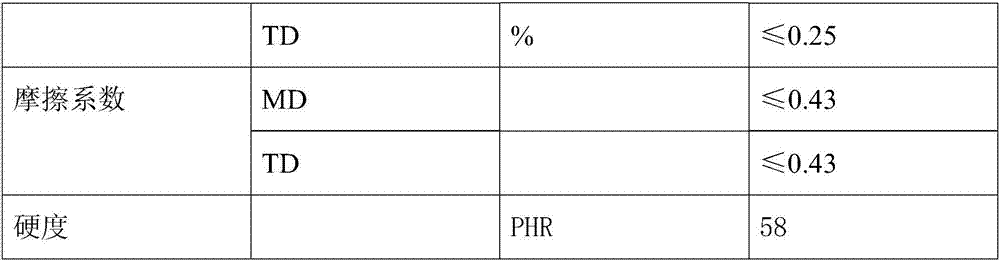

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com