Sheet material

A sheet and panel technology, applied in sheet/board, application, thermal insulation, etc., can solve the problems of easy rust at the cut of the steel plate, affecting the service life, difficult to guarantee the surface flatness, etc., to achieve flexible assembly, improve strength, avoid The effect of cracking and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the plate provided by the present invention will be described in detail below with reference to the accompanying drawings.

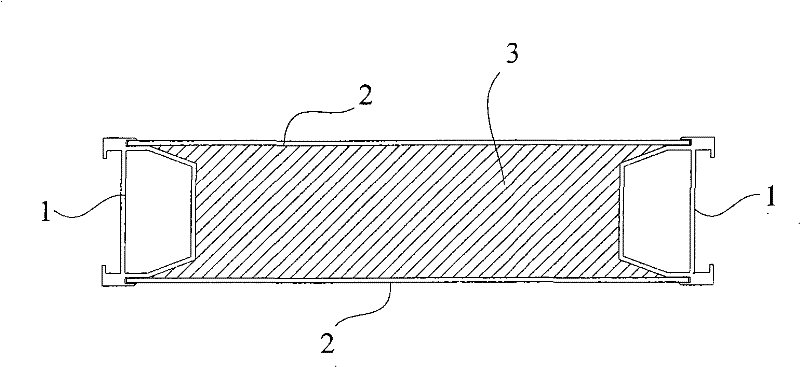

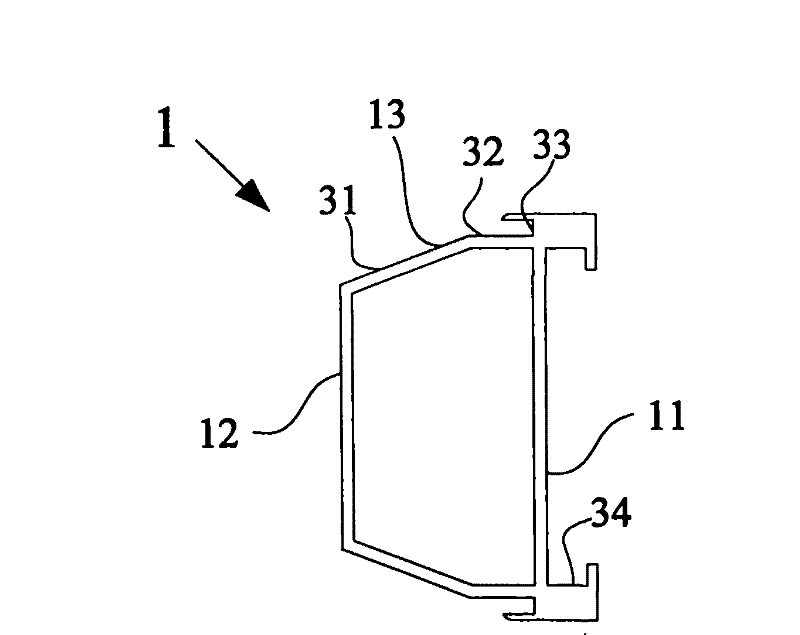

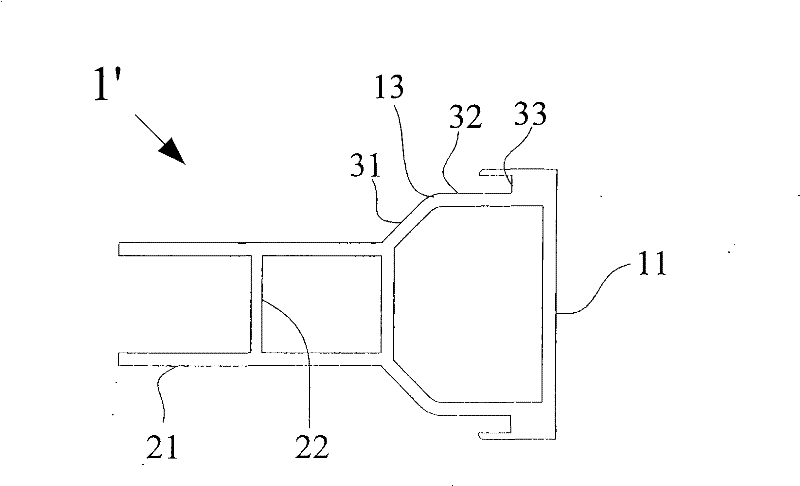

[0032] see figure 1 , is a cross-sectional view of the plate provided in the first embodiment of the present invention along the cross-sectional direction of the frame. Wherein, the board includes a frame 1 and two panels 2 arranged on both sides of the frame 1 , a cavity is formed between the two panels 2 and the frame 1 , and a filler 3 is arranged in the cavity. In this embodiment, the polyurethane foam material is injected into the cavity as the filler 3 by means of high-pressure injection. Of course, the filler 3 is not limited thereto, it can also be any one of benzene board, rock wool strip, or honeycomb paper, but in practical applications, due to the environmental protection aspect of gluing styrene board and rock wool strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com