Electric cable quick winding equipment used for electric cable machining

A cable, fast technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of difficult cable reel cable winding, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

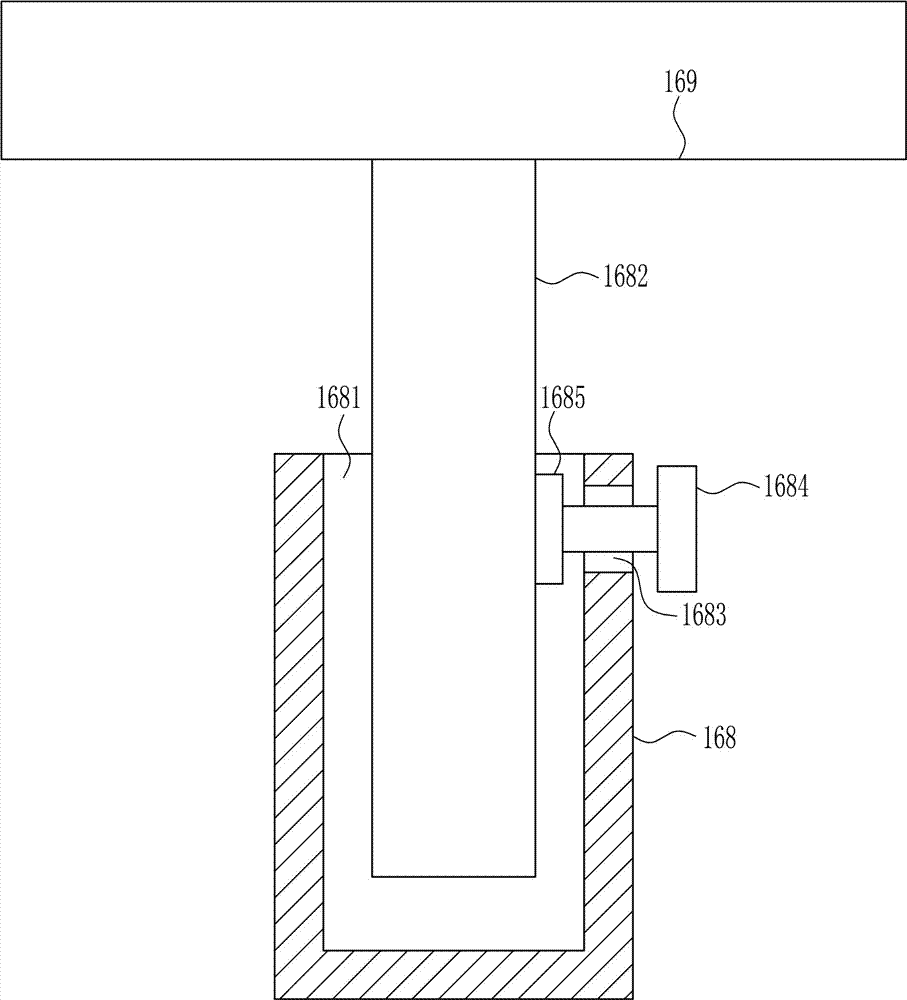

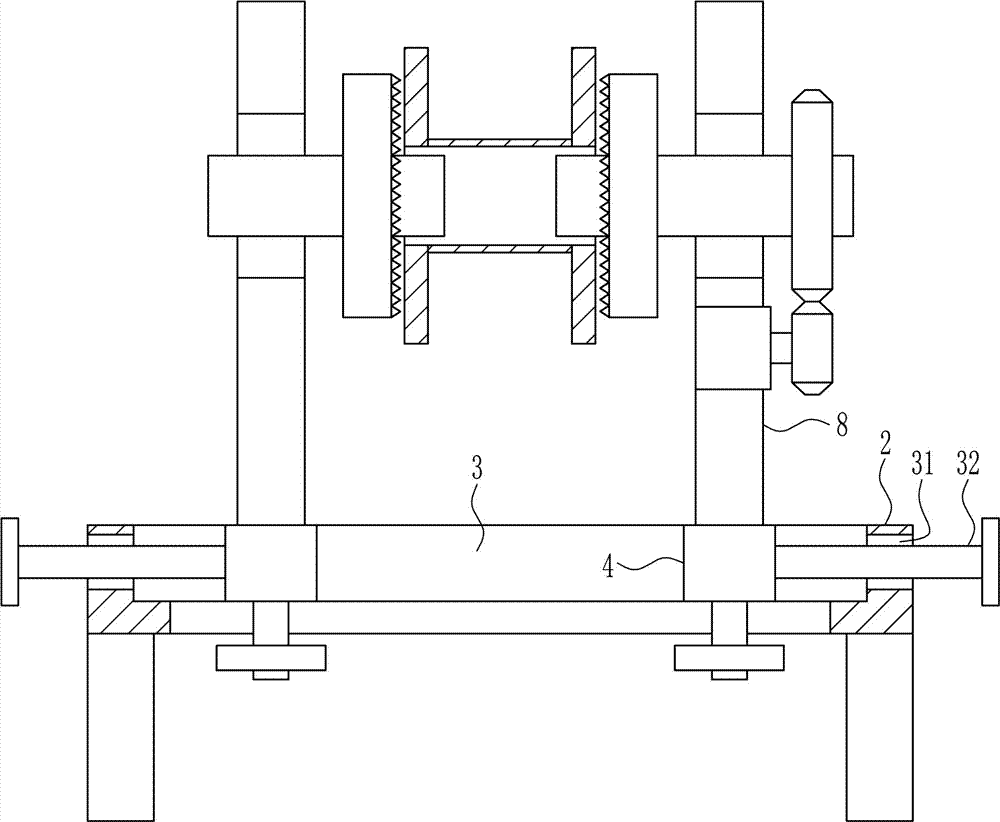

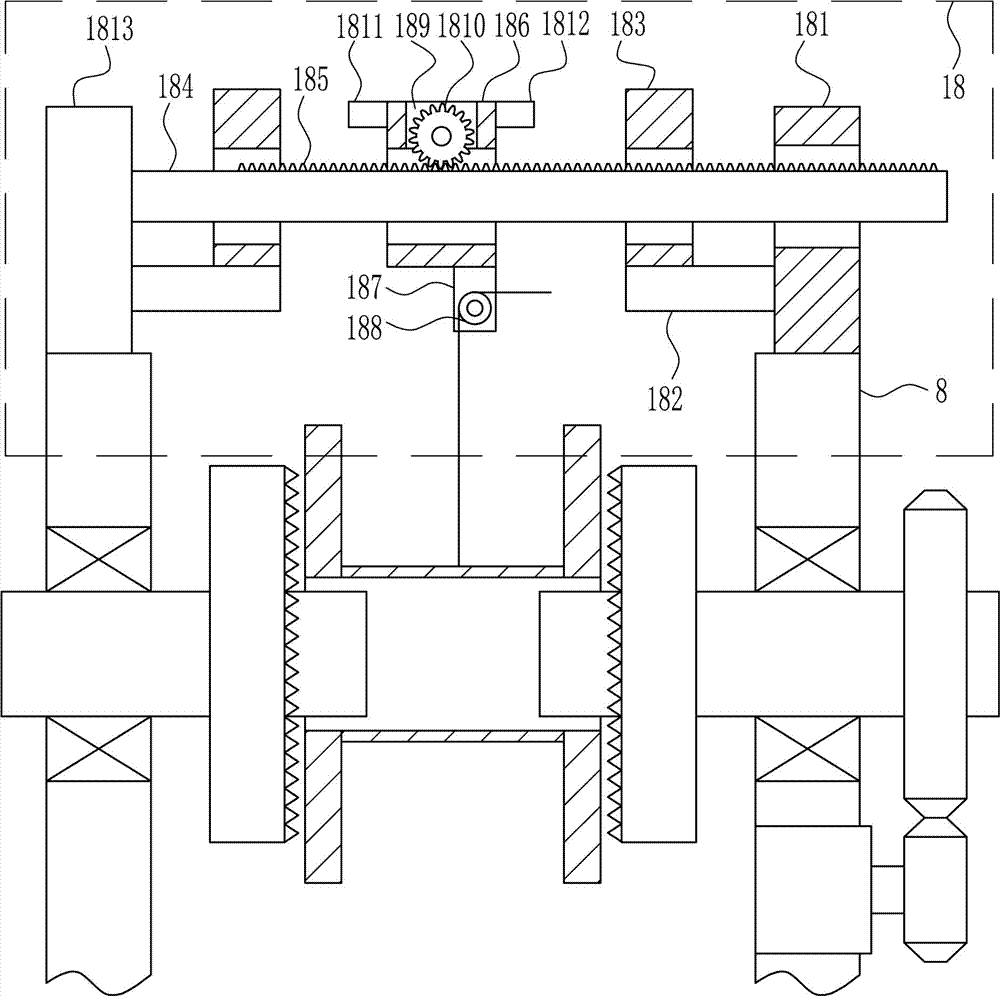

[0038] A kind of cable fast winding equipment for cable processing, such as Figure 1-8 As shown, it includes a pillar 1, a mounting plate 2, a first slide rail 3, a first slider 4, a first screw rod 6, a first nut 7, a support plate 8, a bearing seat 9, a first rotating rod 10, a first The gear 11, the first motor 12, the second gear 13, the pressure plate 14 and the toothed belt 15, the upper ends of the two pillars 1 are installed with the installation plate 2 by welding, and the upper side of the installation plate 2 is installed with the first bolt connection. Slide rail 3, two first sliders 4 are slidably connected in the first slide rail 3, the first slot 5 is opened on the lower side of the mounting plate 2, and the first slotted hole 5 is installed on the lower side of the first slider 4 by welding. A screw rod 6, the first screw rod 6 extends to the bottom of the mounting plate 2 through the first slot 5, the first screw rod 6 is screwed with a first nut 7, the first...

Embodiment 2

[0040] A kind of cable fast winding equipment for cable processing, such as Figure 1-8As shown, it includes a pillar 1, a mounting plate 2, a first slide rail 3, a first slider 4, a first screw rod 6, a first nut 7, a support plate 8, a bearing seat 9, a first rotating rod 10, a first The gear 11, the first motor 12, the second gear 13, the pressure plate 14 and the toothed belt 15, the upper ends of the two pillars 1 are installed with the installation plate 2 by welding, and the upper side of the installation plate 2 is installed with the first bolt connection. Slide rail 3, two first sliders 4 are slidably connected in the first slide rail 3, the first slot 5 is opened on the lower side of the mounting plate 2, and the first slotted hole 5 is installed on the lower side of the first slider 4 by welding. A screw rod 6, the first screw rod 6 extends to the bottom of the mounting plate 2 through the first slot 5, the first screw rod 6 is screwed with a first nut 7, the first ...

Embodiment 3

[0043] A kind of cable fast winding equipment for cable processing, such as Figure 1-8 As shown, it includes a pillar 1, a mounting plate 2, a first slide rail 3, a first slider 4, a first screw rod 6, a first nut 7, a support plate 8, a bearing seat 9, a first rotating rod 10, a first The gear 11, the first motor 12, the second gear 13, the pressure plate 14 and the toothed belt 15, the upper ends of the two pillars 1 are installed with the installation plate 2 by welding, and the upper side of the installation plate 2 is installed with the first bolt connection. Slide rail 3, two first sliders 4 are slidably connected in the first slide rail 3, the first slot 5 is opened on the lower side of the mounting plate 2, and the first slotted hole 5 is installed on the lower side of the first slider 4 by welding. A screw rod 6, the first screw rod 6 extends to the bottom of the mounting plate 2 through the first slot 5, the first screw rod 6 is screwed with a first nut 7, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com