Automatic loading-unloading system

A technology of automatic loading, unloading and moving, applied in the field of mechanical processing, can solve the problems of low degree of automation and low cutting efficiency, and achieve the effect of high reclaiming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

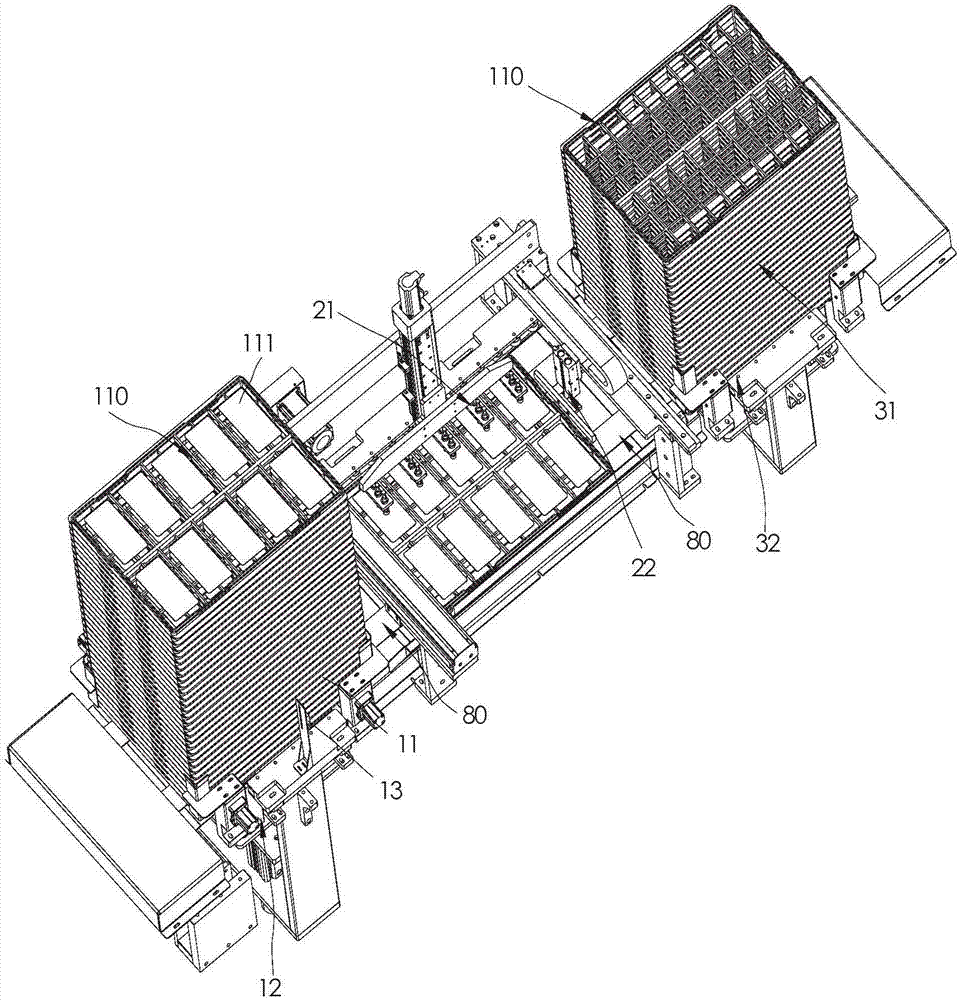

[0042] Such as Figure 1-5 The shown automatic loading and unloading system includes a frame 100, a first conveying mechanism 80, a feeding mechanism 10, a retrieving mechanism 21, a blanking mechanism 30, a positioning mechanism 40, and a material inserting manipulator 50. The frame 100 is provided with an upper Material station, reclaiming station 20, positioning station, unloading station, and inserting slot 61. The loading station, the retrieving station 20 and the unloading station can be arranged sequentially along the conveying direction of the first conveying mechanism 80 .

[0043] A stacking space 11 is provided at the loading station, and the stacking space 11 is used for stacking a plurality of brackets 110 loaded with workpieces 111 , and the brackets 110 are stacked along the height direction of the stacking space 11 . A discharge openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com