Hardware rust removal device capable of recovering scrap iron

A hardware and rust technology, which is applied in the field of hardware rust removal and cleaning devices, can solve the problems of chemical rust removal such as pollution, full utilization, and a lot of iron filings, and achieves good rust removal effect, simple overall structure, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

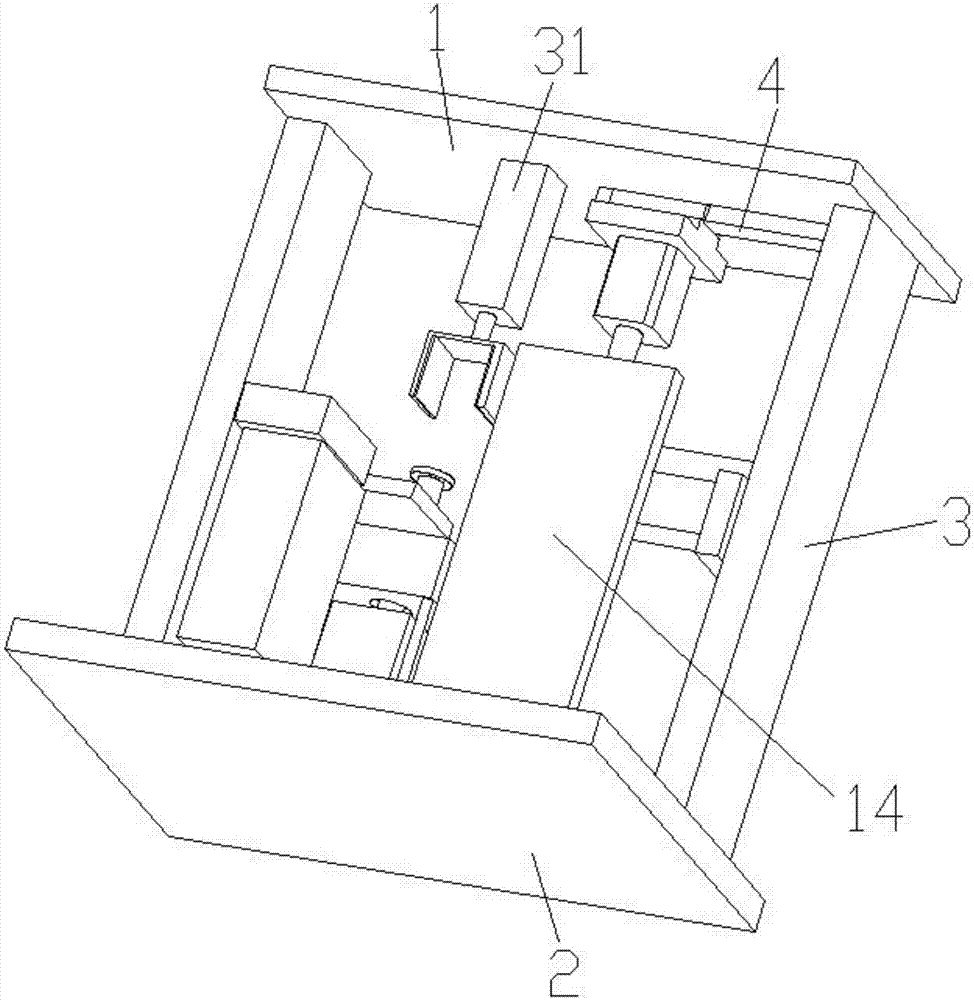

[0019] as attached Figure 1-5 The shown hardware rust removing device capable of recovering iron filings according to the present invention includes a first base plate 1, a second base plate 2, a support block 3, a first slide rail 4, a second slide rail 5, and a grinding assembly , the third slide rail 6, telescopic cylinder 7, U-shaped electromagnet 8, frosted assembly, positioning rod 9, accommodating frame 10, air injection port 11, supporting cylinder 12, circular electromagnet 13 and sealing assembly; the first The base plate 1 and the second base plate 2 are connected up and down through the support block 3; the lower end of the first base plate 1 and the upper end of the second base plate 2 are respectively provided with a first slide rail 4 and a second slide rail 5, and the first Both the slide rail 4 and the second slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com