Anti-oxidation ball mill

A technology of oxidizing balls and ball mills, applied in grain processing, etc., can solve problems such as loss of performance, increase in surface area, and increase in air contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

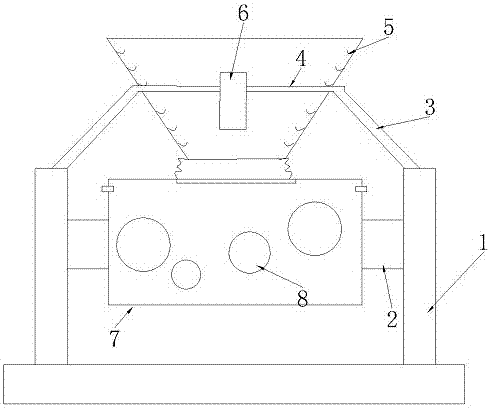

[0016] The reference signs in the drawings of the description include: frame 1, rotating shaft 2, bracket 3, cross bar 4, chute 5, inertia hammer 6, cylinder body 7, and grinding ball 8.

[0017] The embodiment is basically as figure 1 Shown:

[0018] The anti-oxidation ball mill of the present embodiment comprises a frame 1 and a cylinder 7, a plurality of grinding balls 8 are placed in the cylinder 7, a rotating shaft 2 is installed on the frame 1, and the rotating shaft 2 can rotate under the action of an external motor, and the rotating shaft 2 A cylinder 7 is welded in the middle of the cylinder, and the side wall of the cylinder 7 is provided with a material door for feeding and discharging materials. The top of the frame 1 is also provided with an inclined bracket 3, and the top of the bracket 3 is movable to install a hopper. A cross bar 4 that runs through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com