Carbon-doped ultrathin bismuth tungstate nanosheet photocatalytic material and preparation method thereof

A technology of ultra-thin bismuth tungstate and photocatalytic materials, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc., can solve problems of low electrical conductivity, low photocatalytic reduction efficiency, and low exposure surface Active sites and other issues, to achieve the effect of low recombination efficiency, excellent visible light response and charge transfer ability, and improved solar energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The synthesis process of carbon-doped ultrathin bismuth tungstate nanosheet photocatalytic material is as follows:

[0040] 1) Na 2 WO 4 , a certain amount of cetyltrimethylammonium bromide (CTAB) was dissolved in distilled water to form a uniform solution, wherein the concentration of CTAB was 0.625mg / mL; 2) Bi(NO 3 ) 3 Pour the powder into the solution obtained in step 1), and stir rapidly for more than 1 hour until the solution turns milky white, wherein the molar ratio of CTAB:W:Bi is 1:7:14, and pour the obtained solution into a 50ml polytetrafluoroethylene reaction kettle reacted at 120°C for 24 hours, and the resulting precipitate was washed 3 times with water and ethanol, filtered and dried to obtain an ultra-thin bismuth tungstate nanosheet photocatalytic material; 3) the ultra-thin tungstic acid containing residual CTAB obtained in step 2) Bismuth nanosheets were placed in a tube furnace in N 2 The carbon-doped ultrathin bismuth tungstate nanosheet photoca...

Embodiment 2

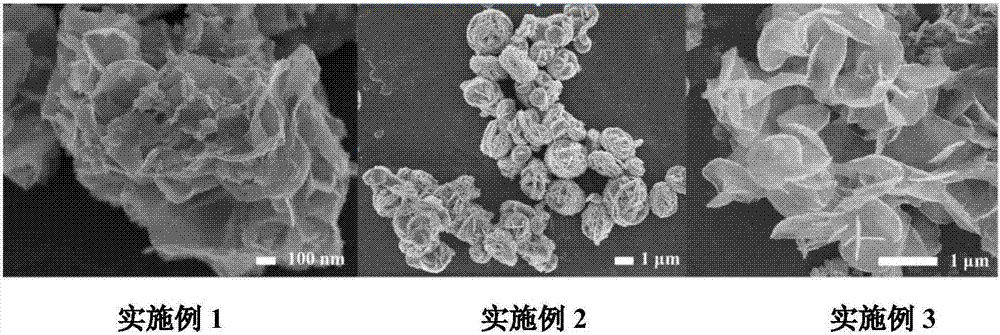

[0050] In order to examine the effect of CTAB on the morphology and structure of carbon-doped bismuth tungstate nanosheet photocatalyst materials, except for CTAB, other reaction conditions are as follows: sample addition sequence, stirring time, W:Bi ratio, reaction temperature (120°C), reaction Time (24h), heat treatment time (1h), temperature (350 ℃) etc. are all identical with embodiment 1. The results showed that when no CTAB was added, since no CTAB was inserted into Bi 2 WO 6 Between molecular layers, Bi 2 WO 6 In the hydrothermal synthesis process, thick sheets self-assemble into a spherical structure. Compared with the carbon-doped ultra-thin bismuth tungstate nanosheets in Example 1, the ultra-thin two-dimensional nanosheet structure cannot be formed, nor can it be calcined for doping modification. . When the concentration of CTAB is adjusted in the range of 0.5-0.7 mg / mL, bismuth tungstate nanosheets with ultrathin structure can be obtained. Therefore, during t...

Embodiment 3

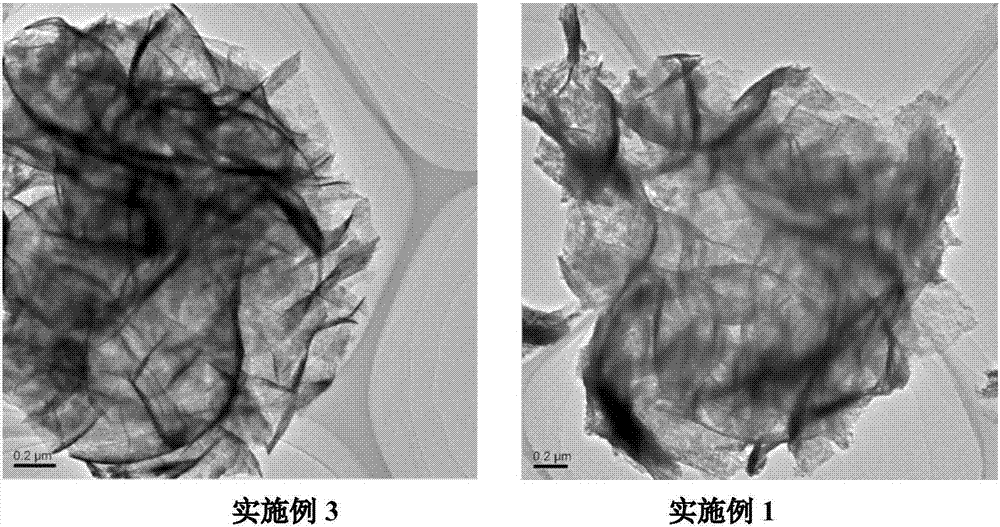

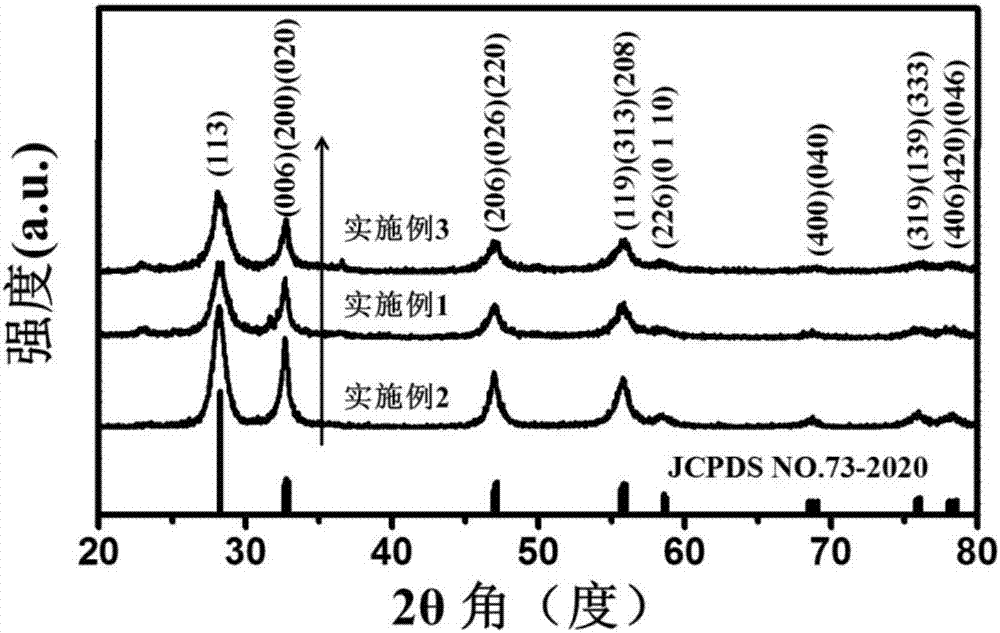

[0052] In order to test the influence of carbon doping on the photocatalytic material of ultra-thin bismuth tungstate nanosheets, in addition to not heat-treating the sample, and using deionized water, ethanol, and isopropanol to wash the sample several times to ensure that CTAB is cleaned, Other reaction conditions are as follows: sample addition order, stirring time CTAB:W:Bi ratio, reaction temperature (120°C), reaction time (24h), etc. are the same as in Example 1. Reference Example 1 carries out XRD, SEM, BET, CO 2 Adsorption and other tests. See the results separately Figure 1-9 .

[0053] Show comprehensively by above-mentioned result: by the carbon-doped ultrathin bismuth tungstate nanosheet photocatalyst material that obtains in embodiment 1, compare with the bulk bismuth tungstate of embodiment 2, specific surface area improves greatly, electron-hole pair Reduced recombination efficiency, enhanced visible light absorption performance, CO 2 The adsorption capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com