Vertical shaft planet stirring machine capable of lifting materials

A planetary mixer and planetary mixing technology, applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of difficult transportation of finished mixers, lack of forced material lifting, and restrictions on large-scale mixers, etc., to achieve benefits Effects of transportation and upsizing, good mixing quality, and reduced diameter-to-height ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

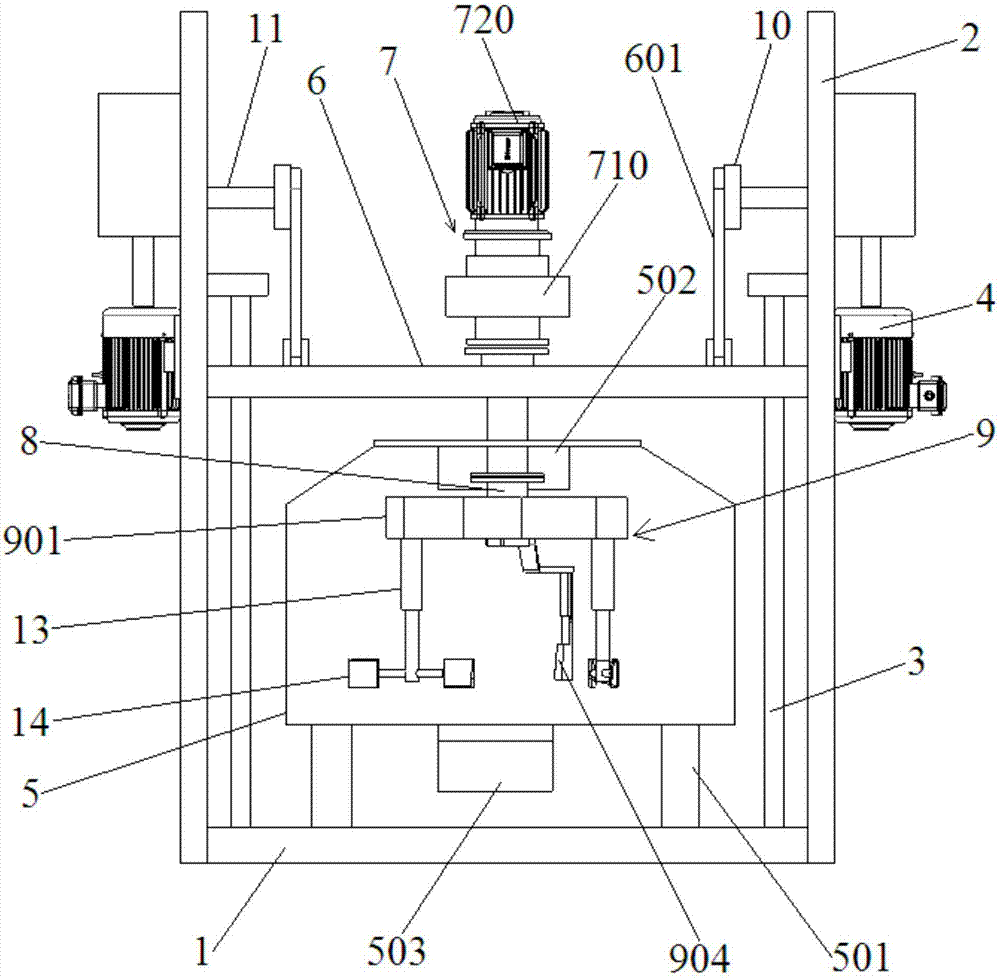

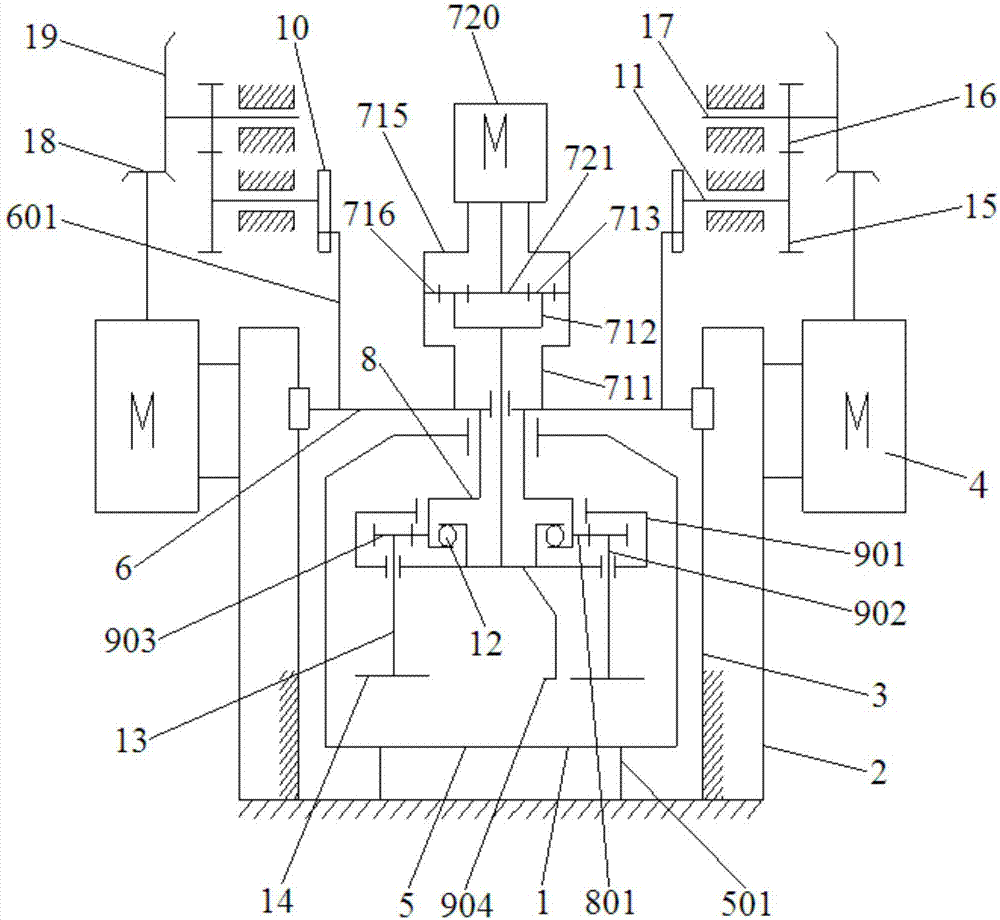

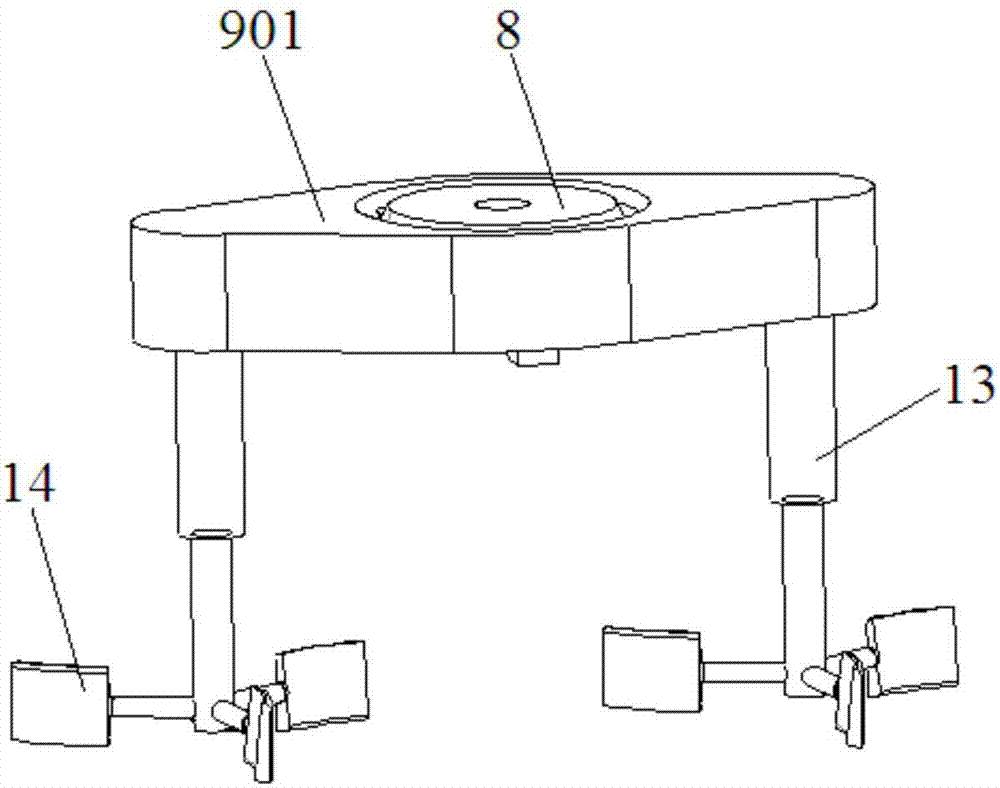

[0027] refer to figure 1 and figure 2 , the embodiment of the present invention proposes a kind of lifting type vertical shaft planetary mixer, comprises: base 1, mixing drum 5, stirring frame 6, planetary mixer 9 and two lifting cranks 10, the two ends of described base 1 are respectively arranged There is a column 2, a longitudinal guide rod 3 is provided on the inner side of the two columns 2, and a lifting motor 4 is provided on the outer side of the two columns 2; the mixing drum 5 is fixed by the support leg 501 On the base 1, the upper end of the mixing drum 5 is provided with a stirring port, one side of the stirring port is provided with a material inlet 502, and the bottom of the mixing drum 5 is provided with a discharge door 503; The two ends of 6 are slidably matched with the two guide rods 3 respectively through sliding holes, and a connecting rod 601 is respectively hinged on the upper sides of the two ends of the stirring frame 6, and a stirring rod 601 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com