Damp-proof bag for storing purple sweet potato for extracting anthocyanin

A technology of anthocyanins and purple sweet potatoes, applied in the fields of application, food preservation, botanical equipment and methods, etc., can solve the problems of mold, rot, and purple sweet potato infection in purple sweet potatoes, reduce preparation costs, prevent rot, and avoid resources wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

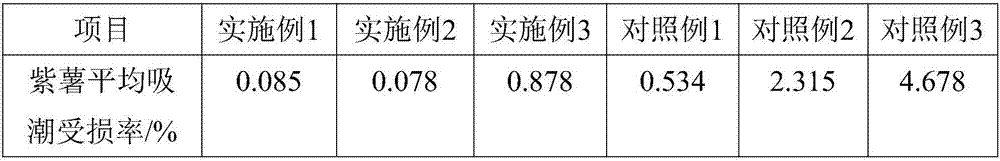

Examples

Embodiment 1

[0025] (1) Add 10 parts of activated clay and 1 part of polyaluminum ferric chloride to 15 parts of fly ash, mix well and roast at 350-400°C for 1 hour to obtain powder I;

[0026] (2) Add 2 parts of hydrogenated castor oil and 0.5 parts of N-methylol acrylamide to 2 parts of polyvinyl alcohol resin, and heat up to 115-120 °C at a heating rate of 5 °C / min and mix for 30 minutes, then add 0.5 Part of polydimethyldiallyl ammonium chloride, continue to mix at 115-120 ° C for 10 minutes, and then make a micropowder through an ultrafine pulverizer to obtain powder II;

[0027] (3) Add 10 parts of microcrystalline cellulose, 5 parts of polyglutamic acid cross-linked polyvinylpyrrolidone and 0.5 parts of potassium dihydrogen phosphate to powder I, and raise the temperature to 105-110 at a heating rate of 5°C / min. ℃ heat preservation and mixing for 15 minutes, then cool down naturally, after the temperature drops to 50-55 ℃, add 5 parts of pregelatinized starch, 5 parts of pregelatini...

Embodiment 2

[0032] (1) Add 5 parts of activated clay and 1 part of polyaluminum ferric chloride to 20 parts of fly ash, mix well and roast at 350-400°C for 1 hour to obtain powder I;

[0033] (2) Add 1 part of hydrogenated castor oil and 0.5 part of N-methylol acrylamide to 3 parts of polyvinyl alcohol resin, and heat up to 115-120 °C at a heating rate of 5 °C / min and mix for 30 minutes, then add 0.5 Part of polydimethyldiallyl ammonium chloride, continue to mix at 115-120 ° C for 10 minutes, and then make a micropowder through an ultrafine pulverizer to obtain powder II;

[0034] (3) Add 10 parts of microcrystalline cellulose, 3 parts of polyglutamic acid cross-linked polyvinylpyrrolidone and 0.5 parts of potassium dihydrogen phosphate to powder I, and raise the temperature to 105-110 at a heating rate of 5°C / min. ℃ heat preservation and mixing for 15 minutes, then cool down naturally, after the temperature drops to 50-55 ℃, add 10 parts of pregelatinized starch, 3 parts of pregelatinize...

Embodiment 3

[0039] (1) Add 5 parts of activated clay and 1 part of polyaluminum ferric chloride to 20 parts of fly ash, mix well and roast at 350-400°C for 1 hour to obtain powder I;

[0040] (2) Add 1 part of hydrogenated castor oil and 0.5 part of N-methylol acrylamide to 3 parts of polyvinyl alcohol resin, and heat up to 115-120 °C at a heating rate of 5 °C / min and mix for 30 minutes, then add 0.5 Part of polydimethyldiallyl ammonium chloride, continue to mix at 115-120 ° C for 10 minutes, and then make a micropowder through an ultrafine pulverizer to obtain powder II;

[0041] (3) Add 10 parts of microcrystalline cellulose with a degree of polymerization of 200-250, 3 parts of polyglutamic acid cross-linked polyvinylpyrrolidone and 0.5 part of potassium dihydrogen phosphate to powder I, and heat up at 5°C / min Heat up to 105-110°C and mix for 15 minutes, then cool down naturally. After the temperature drops to 50-55°C, add 10 parts of pregelatinized starch, 3 parts of pregelatinized st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com