Method for detecting damage defect of curved tag based on template matching and similarity calculation

A technology of similarity calculation and template matching, applied in computing, image data processing, instruments, etc., can solve problems such as reducing the difficulty of system implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

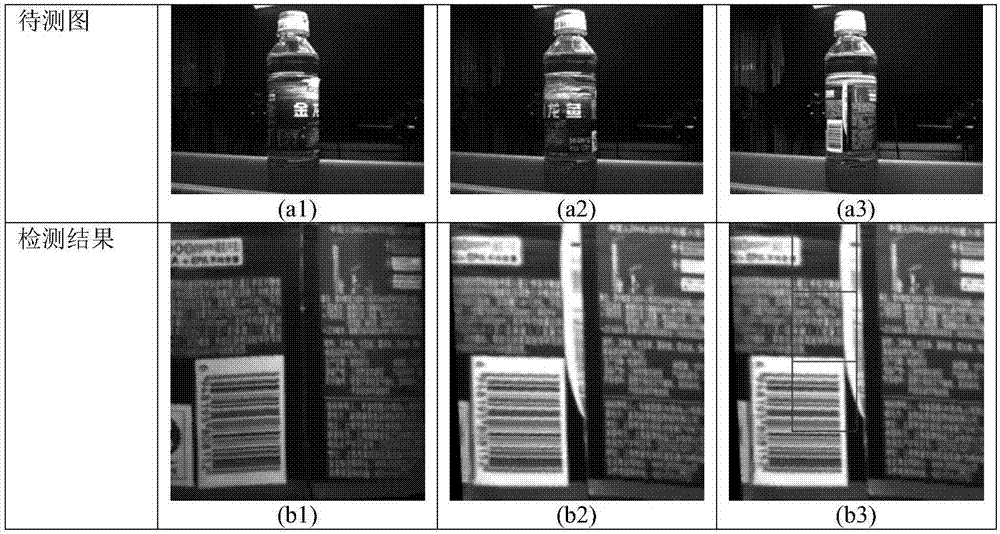

Examples

Embodiment 1

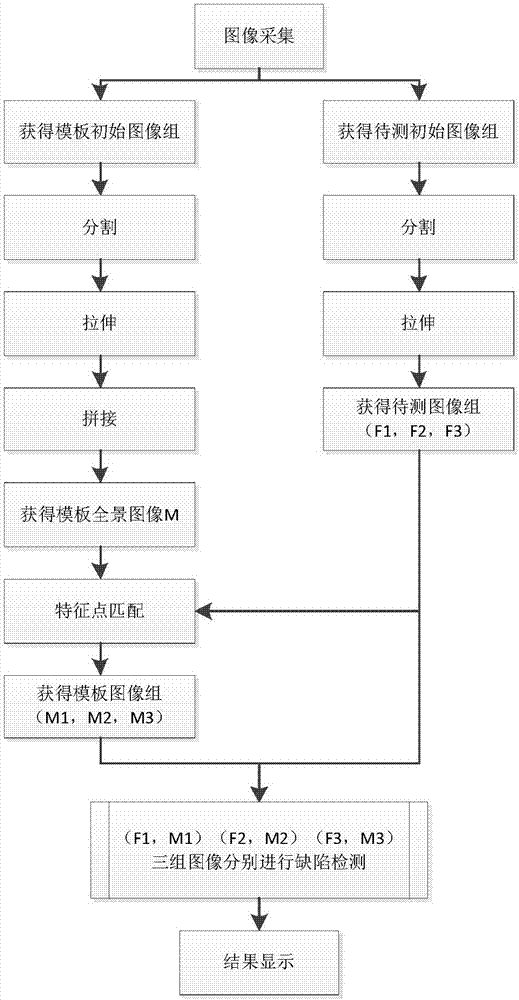

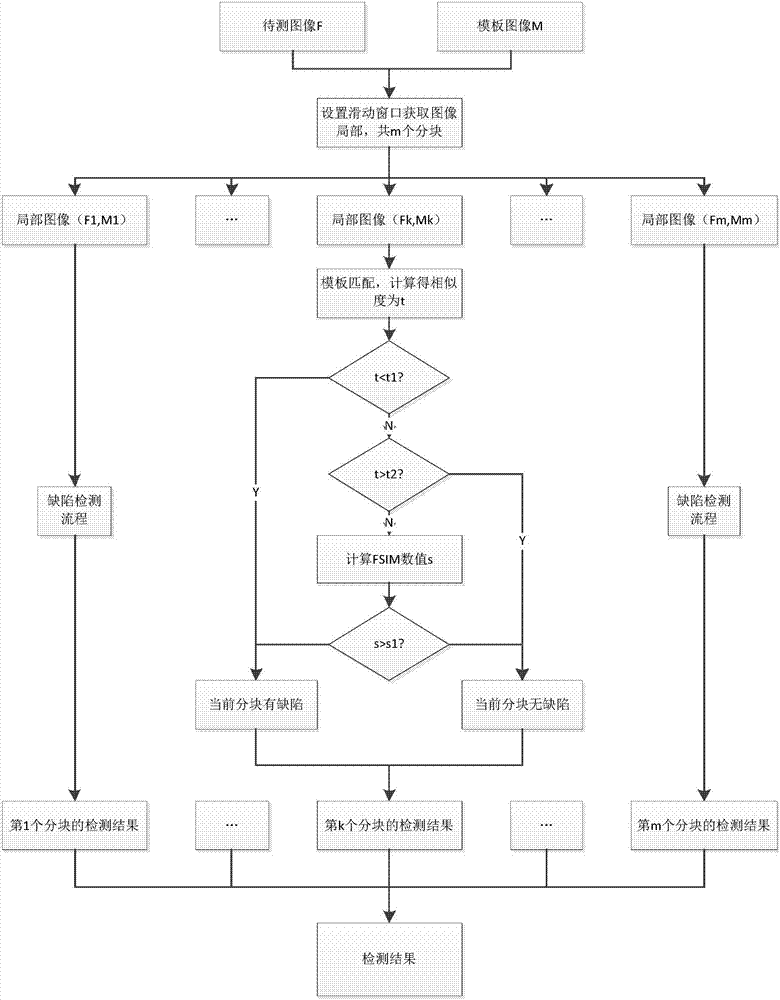

[0067] see figure 1 and figure 2 , the surface label damage defect detection method based on template matching and similarity calculation of the present embodiment includes the following steps:

[0068] image preprocessing

[0069] Image preprocessing includes a series of steps such as image acquisition, image segmentation, image stretching, and template image stitching, which are used to obtain the plane label area of the image to be tested and the plane label panorama area of the template image. The specific steps are as follows:

[0070] (1) Image acquisition:

[0071] Specifically, the CCD camera is used to collect bottle label images in a low-brightness environment. The three cameras are located at the vertices of an equilateral triangle centered on the bottle, and a light source is placed directly below each camera to ensure that each camera The direction of the central axis is kept horizontal and passes through the center of the bottle placement area. The colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com