A double swing head with integrated pneumatic auxiliary chip removal device

An auxiliary chip removal and pneumatic technology, applied in the field of double swing heads, can solve the problems of limited tool processing angle and range, waste chip pollution, inability to track blowing chips in all directions, and achieve the effect of preventing intrusion and ensuring machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

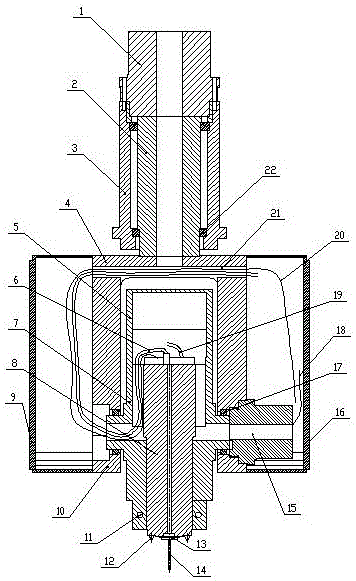

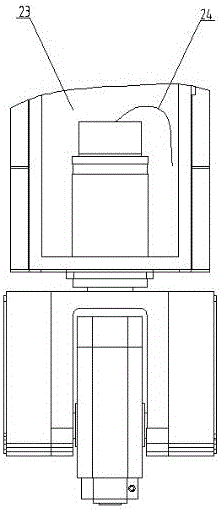

[0019] see figure 1 , which schematically shows a preferred embodiment of a double swing head integrated with a pneumatic auxiliary chip removal device provided by the present invention. As shown in the figure, the double swing head includes: an A-axis motion device, a C-axis motion device, and a rotating tool device and pneumatic auxiliary chip removal device.

[0020] Specifically, the C-axis motion device includes a C-axis drive unit 1 located inside the Z-axis base 23 and a C-axis bearing seat 3 mounted on the bottom of the Z-axis base 23; the C-axis drive unit 1 is fixed to the C-axis bearing seat by bolts 3. A pair of deep groove ball bearings 22 are installed on the upper and lower sides of the C-axis bearing seat 3 , and the rotating shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com