Motor vehicle body

A technology of automobile body and plate, applied in the direction of vehicle parts, connecting members, thin plate connection, etc., can solve problems such as twisting, bending of lining elements, damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

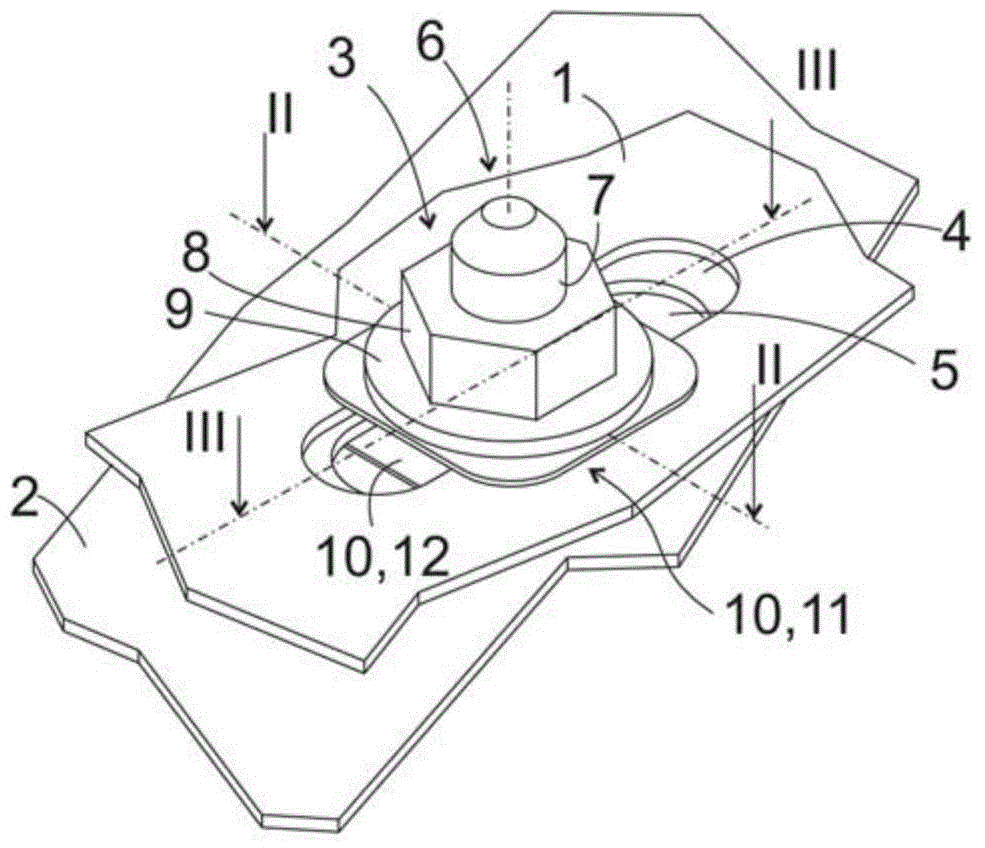

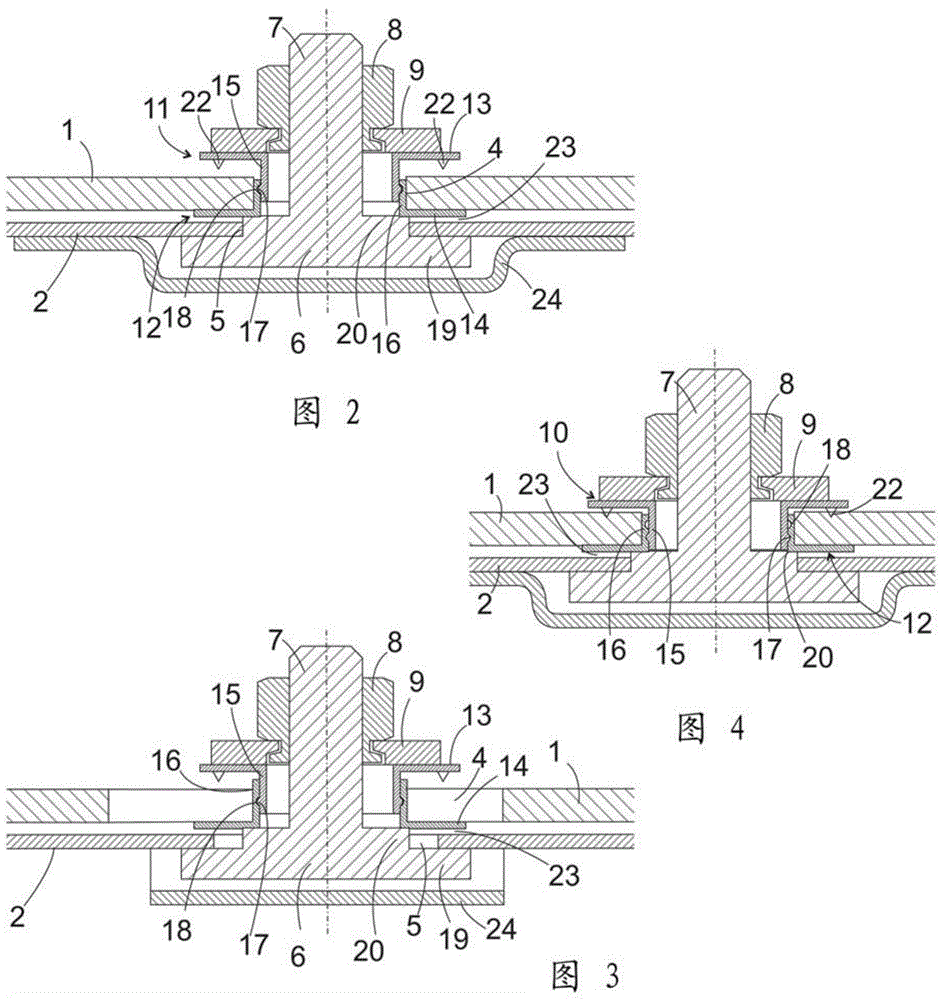

[0022] figure 1 A perspective view of a section of a first panel 1 and a second panel 2 is shown, clamped and fixed by a connection assembly 3 extending through the panels 1, 2 slotted holes 4,5. The longitudinal axes of the elongated holes 4, 5 are parallel to each other and are oriented along the plane marked III-III.

[0023] The panel 1 made of plastic, in particular fiber-reinforced plastic, is part of a lining element of a motor vehicle body which is not visible from the outside in the assembled vehicle. The lining element can be, for example, a fender, a door, a lid or the like. In contrast, the panel 2 is made of metal, in particular sheet steel, and is part of the supporting structure of the vehicle body. In particular, the second plate part can be a part of the frame rail or a frame part fastened to the frame rail.

[0024] The connection assembly 3 here comprises bolts 6 (however from figure 1 Only the tip of the screw 7 can be seen in ), the nut 8 screwed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com