High-torque-output fuel-saving energy-saving piston engine

A piston engine, high torque technology, used in combustion engines, machines/engines, mechanical equipment, etc., can solve problems such as low energy density, shutdown and flameout, incomplete combustion, etc., to improve energy density and power, reduce fuel leakage, complete burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is further described:

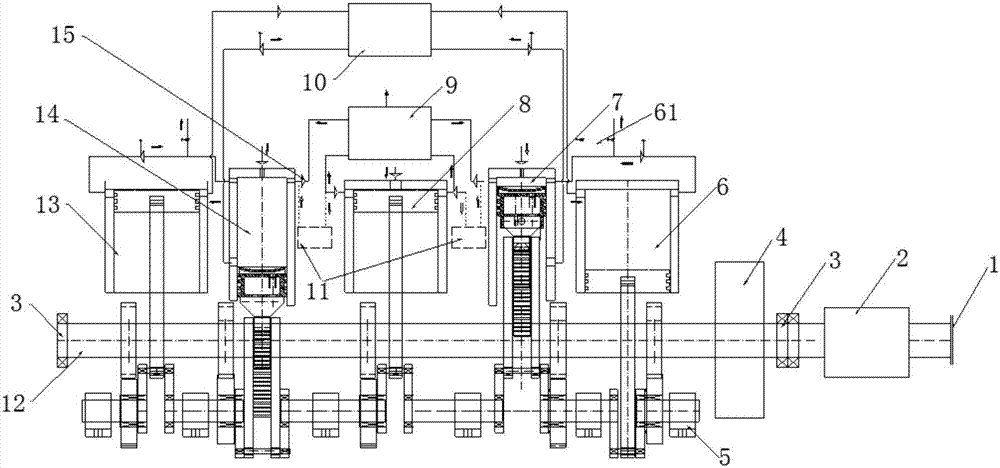

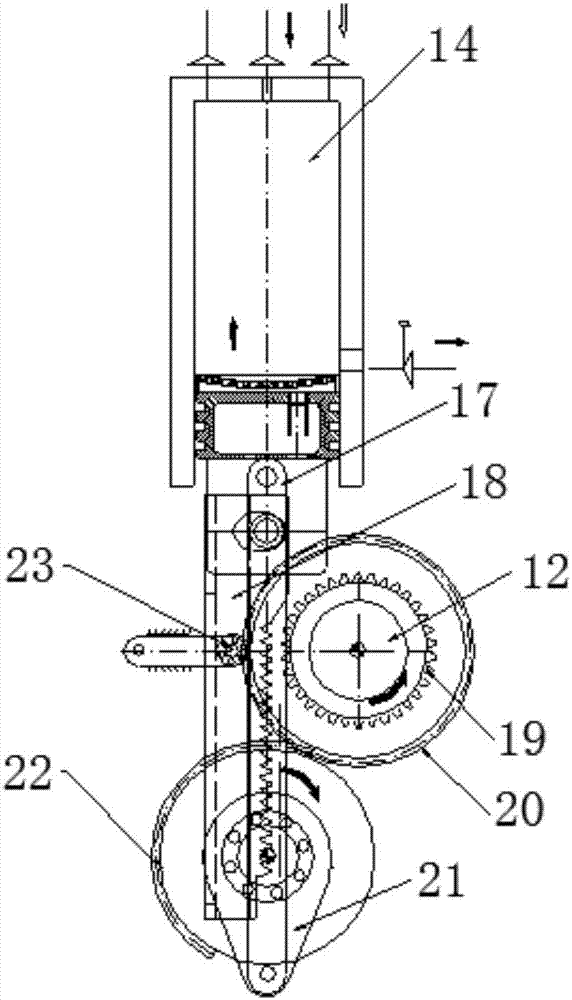

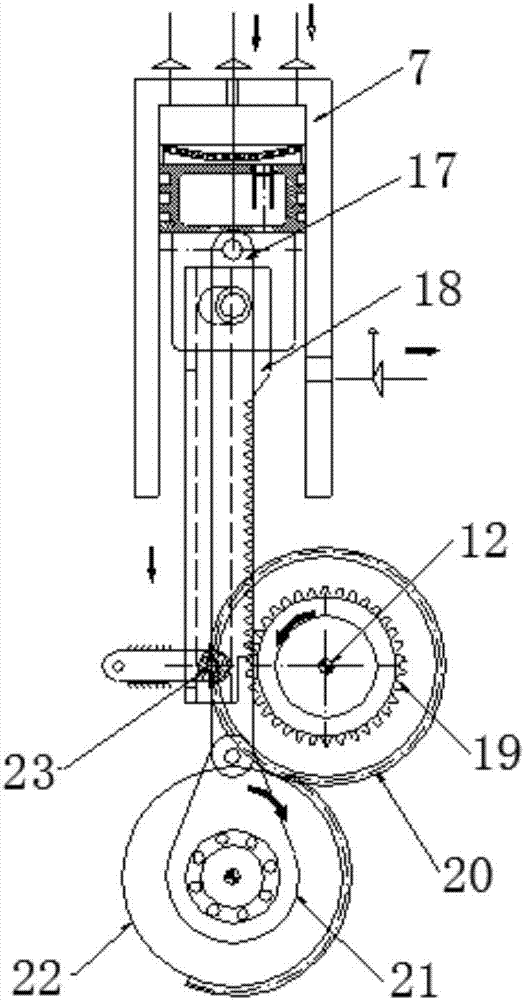

[0030] Such as figure 1 As shown, a fuel-efficient and energy-saving piston engine with high torque output includes an output shaft 12, a first combustion working cylinder 14, a second combustion working cylinder 7, an output end of the first combustion working cylinder 14, and the second combustion working cylinder The output ends of the cylinders 7 are all connected to the output shaft 12; the end of the output shaft 12 close to the second combustion working cylinder 7 is provided with a flywheel 4, a gearbox 2 and a clutch 1 sequentially from left to right.

[0031] Bearings 3 are provided on the output shaft 12 between the flywheel 4 and the gearbox 2 and on the output shaft 12 away from the end of the flywheel 4 .

[0032] Described engine also comprises heat exchanger and fresh air storage tank 9, and the gas outlet of described naturally aspirate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com