Waterproof top cover and construction method thereof

A construction method and roof technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of easy cracking and failure of rigid waterproof layers, easy damage to flexible waterproofing, and difficult problems of roof waterproofing durability. Avoid man-made and external damage, flexible processing methods, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

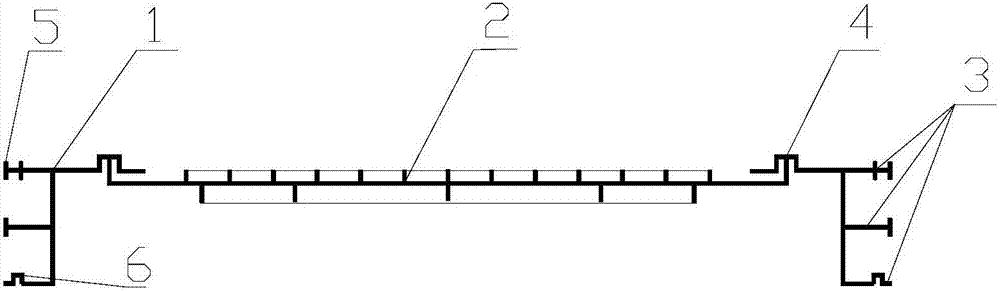

[0026] Embodiment 1: A waterproof top cover, which includes a waterproof frame 1 and a waterproof web 2, the waterproof frame 2 is rectangular, the length and width are 2.1 meters, the length and width of the internal cavity are 1.9 meters, and the frame is wide 0.1 meters, the cross-section is straight, the thickness is 5 mm, there is a ring-shaped water-stop convex rib on the upper and lower surfaces of the free end, 5 is 20 mm wide, and 10 mm thick, and there is a ring-shaped water-stop groove at the connecting end One 4 is 20 mm wide and 10 mm deep. The panel of the waterproof web 2 is 5 mm thick. There is a ring-shaped closed connection convex rib on the bottom surface of the panel periphery. The size corresponds to the water-stop groove-4. Forming, factory mass production.

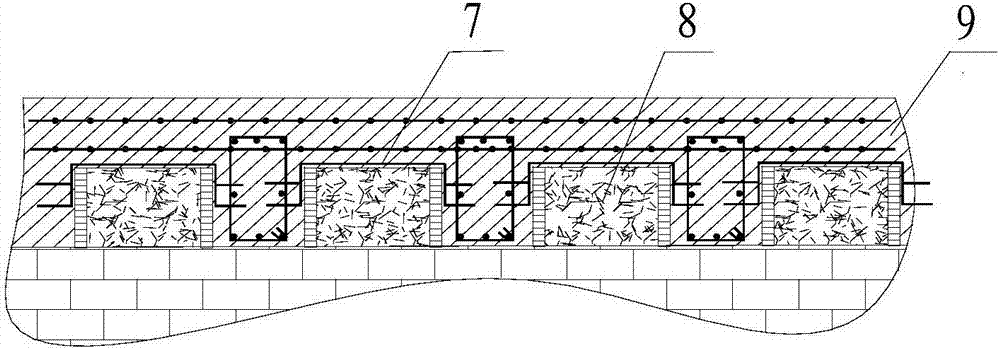

[0027] Further, the above-mentioned waterproof top cover and the mandrel 8 are used to form a concrete hollow board, the top surface of the mandrel 8 is covered with the waterproof top cover 7, and a...

Embodiment 2

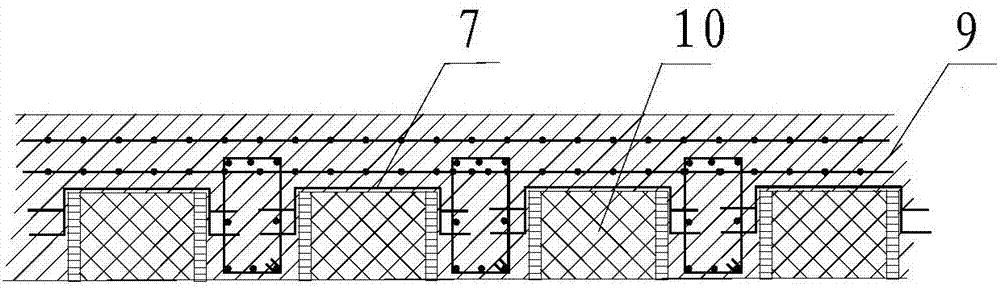

[0035] Embodiment 2: A waterproof top cover, the section form of the water-stop frame 1 is inverted L-shaped, there are two circles of water-stop grooves 26 on the outer surface of the free limb, and there is a ring-shaped connection groove at the end of the connecting limb. The surface of the waterproof web 2 has grid-like convex ribs, the rib height is 2 mm, the rib width is 3 mm, and the rib distance is 50 mm, and the rest are the same as in embodiment 1.

[0036] Use the above-mentioned waterproof top cover and mandrel 8 to form a concrete hollow board. The gap reserved between the mandrels 8 is 400 mm, and the rest are the same as in Example 1.

[0037] The construction method and steps of the above-mentioned concrete hollow slab are as follows:

[0038] 1. The waterproof top cover 7 is prefabricated in batches at the factory and delivered to the construction site;

[0039]2. The anti-floating mandrel 8 is arranged on the in-situ foundation according to the reserved gap ...

Embodiment 3

[0044] Embodiment 3: A waterproof top cover, which includes a waterproof frame 1 and a waterproof web 2, the waterproof frame 2 is rectangular, with a length and width of 2.5 meters, an internal cavity with a length and width of 2.3 meters, and a frame width of 0.1 meters, the cross-section is straight, the thickness is 5 mm, there is a ring-shaped water-stop convex rib on the upper and lower surfaces of the free end, 5 is 20 mm wide, and 10 mm thick, and there is a ring-shaped water-stop groove at the connecting end One 4 is 30 mm wide and 15 mm deep. The panel of the waterproof web 2 is 5 mm thick. There is a ring-shaped closed connecting convex rib on the bottom surface around the panel. The size corresponds to the water-stop groove-4. Forming, factory mass production.

[0045] Use the above-mentioned waterproof top cover and mandrel 8 to form a concrete hollow board. The gap reserved between the mandrels 8 is 400 mm, and the rest are the same as in Example 1.

[0046] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com