A kind of rubber asphalt-based material for expansion joints of concrete structure and preparation method thereof

A technology of concrete structure and rubber asphalt, which is applied in the direction of building insulation materials, building components, building structures, etc., can solve the problems of difficult to achieve the expected performance of materials, unsatisfactory use effect, poor sealing effect of expansion joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

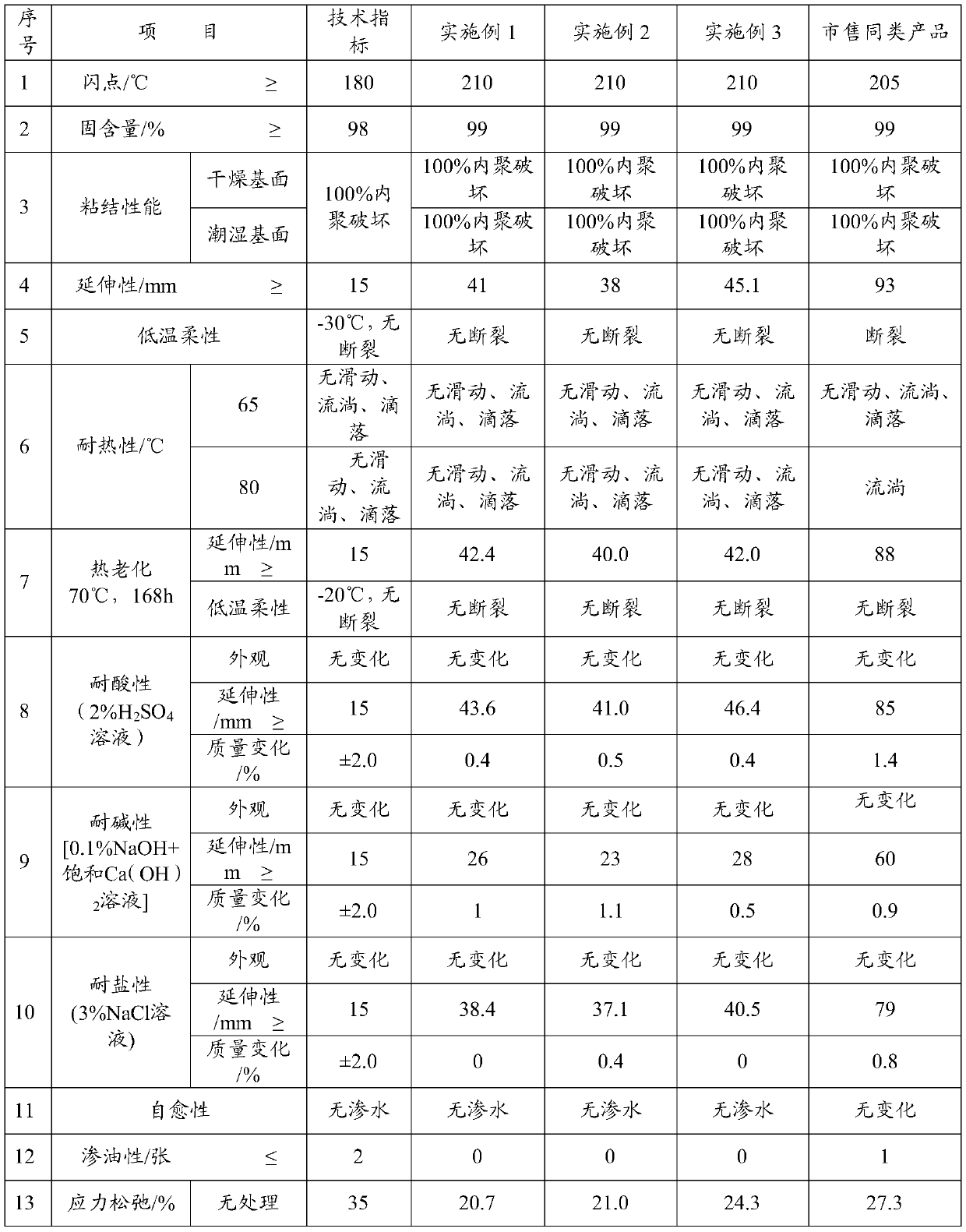

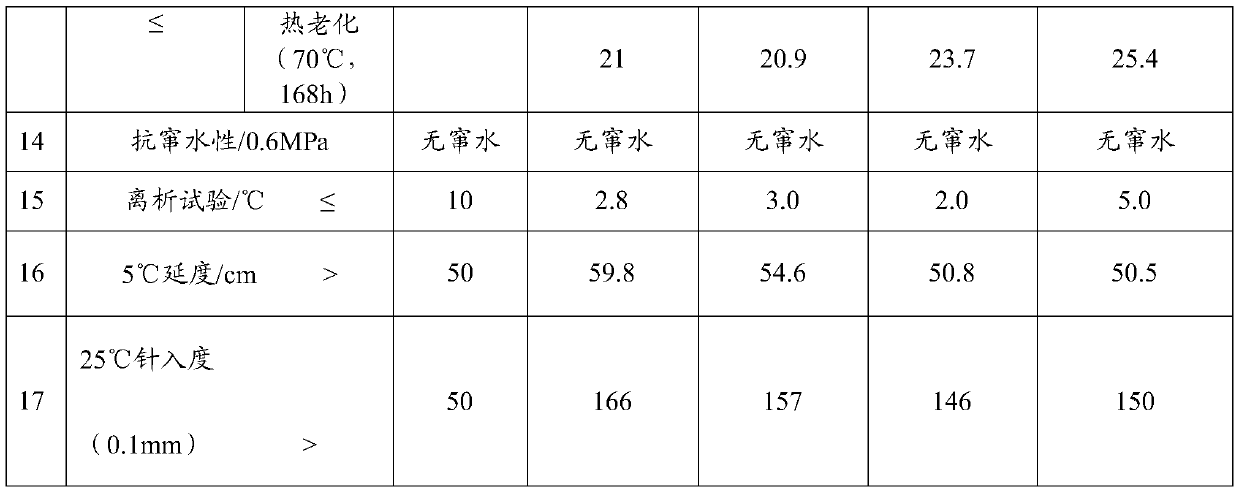

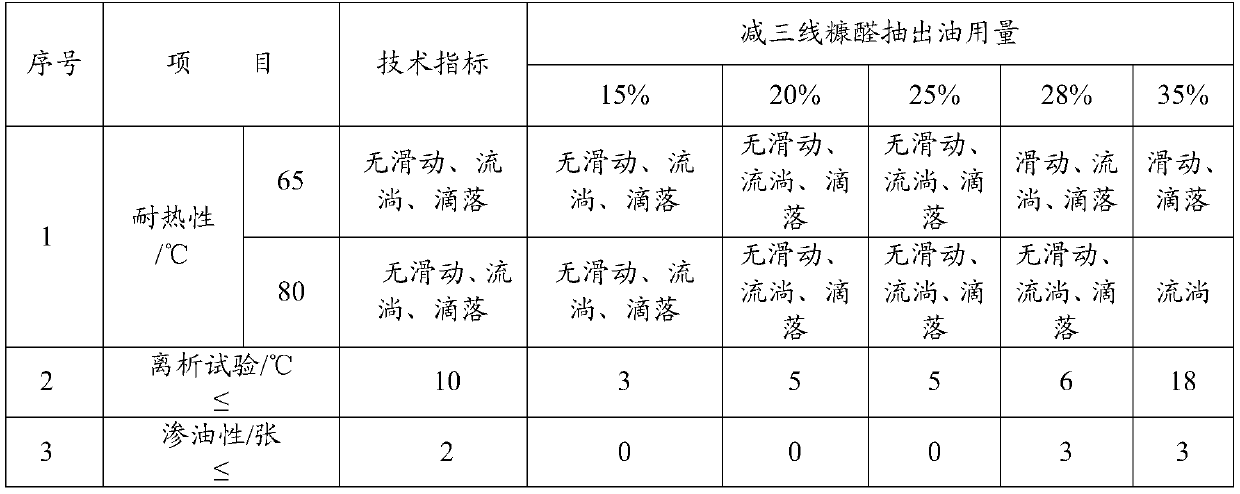

Examples

Embodiment 1

[0059] Embodiment 1: Preparation of rubber asphalt-based material for concrete structure expansion joints according to the present invention

[0060] 1. The raw materials and dosage: asphalt 41.7g, third-line furfural-reduced oil 22.9g, SBS 2.1g, SBR 13.0g, DOS 4.2g, terpene resin 5.2g, PB2400 polyisobutylene 5.1g, POE 4.2g, Honeywell Titan Special asphalt additive 1.6g;

[0061] 2. Preparation method:

[0062] (1) Add the base asphalt heated to 130°C into the mixing pot, raise the temperature to 170°C, start the electric mixer to stir, and the speed is 100-200rpm;

[0063] (2) In the system of step (1), add the third-line furfural-extracted oil, SBS and SBR in sequence, and continue heating and stirring at 170° C., with a rotating speed of 50-100 rpm, until there are no infusible particles;

[0064] (3) In the system of step (2), add DOS, terpene resin, POE, polyisobutylene, special asphalt additives, etc. in sequence, raise the temperature to 180°C, continue heating and s...

Embodiment 2

[0065] Embodiment 2: Preparation of rubber asphalt-based material for concrete structure expansion joints according to the present invention

[0066] 1. The raw materials and dosage: 41.7g of asphalt, 22.0g of furfural-reduced third-line extract oil, 2.1g of SBS, 13.0g of SBR, 2.1g of Fischer-Tropsch wax, 5.2g of DOS, 3.1g of terpene resin, 6.2g of PB2400 polyisobutylene, POE 3.2g, Honeywell Titan special asphalt additive 1.4g;

[0067] 2. Preparation method:

[0068] (1) Add the base asphalt heated to 130°C into the mixing pot, raise the temperature to 170°C, start the electric mixer to stir, and the speed is 100-200rpm;

[0069] (2) In the system of step (1), add the third-line furfural-extracted oil, SBS and SBR in sequence, and continue heating and stirring at 170° C., with a rotating speed of 50-100 rpm, until there are no infusible particles;

[0070] (3) In the system of step (2), add Fischer-Tropsch wax, DOS, terpene resin, POE, polyisobutylene, special asphalt add...

Embodiment 3

[0071] Embodiment 3: Preparation of rubber asphalt-based material for concrete structure expansion joints according to the present invention

[0072] 1. The raw materials and dosage: asphalt 41.0g, third-line furfural-reduced oil 22.0g, SBS 2.1g, SSBR 14.0g, paraffin 2.1g, DOS 5.2g, terpene resin 2.1g, PB2400 polyisobutylene 6.0g, POE2. 0g, vinyltrimethoxysilane 1.5g, Honeywell Titan special asphalt additive 2.0g;

[0073] 2. Preparation method:

[0074] (1) Add the base asphalt heated to 130°C into the mixing pot, raise the temperature to 170°C, start the electric mixer to stir, and the speed is 100-200rpm;

[0075] (2) In the system of step (1), add the third-line furfural-extracted oil, SBS and SSBR in sequence, and continue heating and stirring at 170° C., with a rotating speed of 50-100 rpm, until there are no infusible particles;

[0076] (3) In the system of step (2), add paraffin wax, DOS, terpene resin, POE, polyisobutylene, vinyltrimethoxysilane, special asphalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com