Water reducing agent especially for subway segments and preparation method of same

A technology of subway segment and water reducing agent, which is used in underground chambers, mining equipment, shaft equipment, etc., can solve the problems of high strength grade, high dosage, high concrete viscosity, etc., and achieves improved performance, workability improvement, The effect of improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

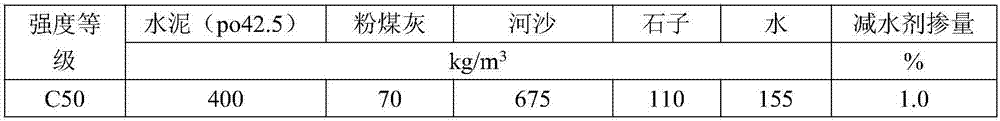

Examples

Embodiment 1

[0017] A special water reducing agent for subway segments, which is characterized in that it is made of the following components: 27% water-reducing polycarboxylate mother liquor, 6% slump-preserving polycarboxylate mother liquor, and 2% viscosity-reducing additive , workability regulator 2.8%, foam control agent 0.09%, water 62.11%.

[0018] The preparation method of the subway segment: add two kinds of water reducer mother liquids into a four-necked flask, stir for 5 minutes, add high-carbon alcohol polyether ester foam control agent, stir for another 15 minutes, then add water with a total water mass of 55% and stir for 5 minutes , then add the workability modifier at a uniform speed, stir for 15 minutes, then add the viscosity reducing agent at a uniform speed and stir for 10 minutes, finally add the remaining water, and stir for 10 minutes to obtain the finished product.

[0019] Among them, the workability regulator is a mixture of potassium sulfate, sodium sulfate, and ...

Embodiment 2

[0021] A special water reducing agent for subway segments, which is characterized in that it is made of the following components: 30% water-reducing polycarboxylate mother liquor, 5% slump-preserving polycarboxylate mother liquor, and 1.5% viscosity-reducing additive , Workability regulator 3%, foam control agent 0.07%, water 60.43%.

[0022] The preparation method of the subway segment: add two kinds of water reducer mother liquors into a four-necked flask, stir for 10 minutes, add high-carbon alcohol polyether ester foam control agent, stir for another 20 minutes, then add water with a total water mass of 55% and stir for 5 minutes , then add the workability modifier at a uniform speed, stir for 15 minutes, then add the viscosity reducing agent at a uniform speed and stir for 15 minutes, finally add the remaining water, and stir for 10 minutes to obtain the finished product.

[0023] Among them, the workability regulator is a mixture of potassium sulfate, sodium sulfate, and...

Embodiment 3

[0025] A special water reducing agent for subway segments, which is characterized in that it is made of the following components: 28% water-reducing polycarboxylate mother liquor, 9% slump-preserving polycarboxylate mother liquor, and 2.5% viscosity-reducing additive , workability regulator 2%, foam control agent 0.1%, water 58.4%.

[0026] The preparation method of the subway segment: add two kinds of water reducer mother liquors into a four-necked flask, stir for 10 minutes, add high-carbon alcohol polyether ester foam control agent, stir for another 20 minutes, then add water with a total water mass of 55% and stir for 5 minutes , then add the workability modifier at a uniform speed, stir for 20 minutes, then add the viscosity reducing agent at a uniform speed and stir for 10 minutes, finally add the remaining water, and stir for 10 minutes to obtain the finished product.

[0027] Among them, the workability regulator is a mixture of potassium sulfate, sodium sulfate, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com