Water washing method and device for purifying calcite ores through rotating drum

A technology of rotary drum and water washing device, which is applied to cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc. It can solve problems such as difficult to remove, ore cannot be rolled over, and the power of the excitation motor is large, so as to save clean water and energy, increase washing output, and ensure the effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

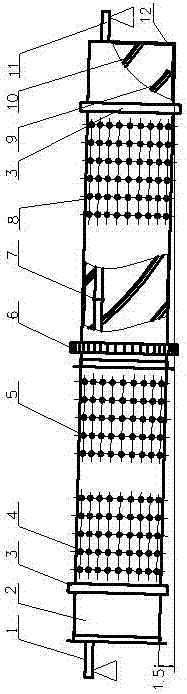

[0017] The invention relates to a water washing method and device for purifying calcite ore by using a rotary drum.

[0018] The main equipment is a rotary drum 2 with a cylindrical shape and a circular aspect ratio of 10:1. The two ends of the rotary drum 2 are equipped with two sets of drum support rings 3 concentric with it. The drum support rings 3 support the rotary drum 2 together. For this purpose, the middle position of the rotary drum 2 is equipped with a large gear 6 concentric with it. When the external power drives the large gear 6, it will drive the rotary drum 2 to rotate in the left-hand direction, and there is washing water on the drum body of the rotary drum 2 Drainage holes 8 in the front section, 5 drainage holes in the washing water section, and 4 drainage holes in the rear section of washing water. These drainage holes are drilled with ø15 holes according to the 80×80 grid, and the entrance end of the rotary drum 2 is welded with a water retaining wall with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com