Device for cleaning lamp tube end surfaces of fluorescent lamps

A technology of cleaning device and fluorescent lamp, which is applied to cleaning methods and utensils, cleaning methods using tools, transmittance measurement, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

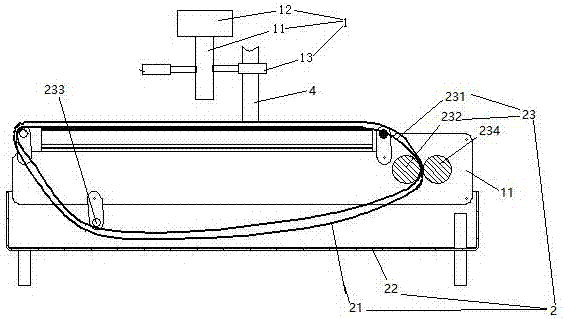

Examples

Embodiment 2

[0031] Embodiment two, the difference with embodiment one is:

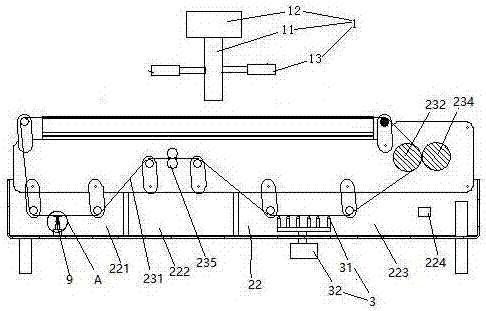

[0032] see figure 2 The water tank 22 is provided with a primary cleaning pool 221 , a sewage storage pool 222 and a secondary cleaning pool 223 in sequence along the moving direction of the conveyor belt 231 .

[0033] A dirt detachment booster mechanism 9 is provided in the primary cleaning tank 221 . A pair of second squeezing rollers 235 are arranged at the sewage storage tank 222 . The secondary cleaning tank 223 is provided with a pair of light-transmitting windows 224 distributed on two opposite side walls of the secondary cleaning tank.

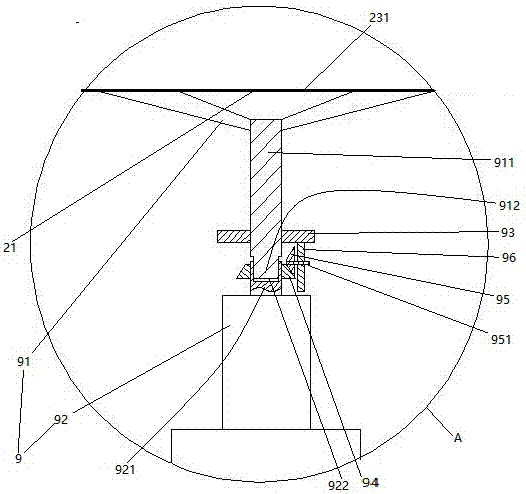

[0034] see image 3 Dirt breaks away from booster mechanism 9 and packs blade 91 and rotary motor 92. The rotating shaft 911 of the blade is provided with a spline connection head 912 and a support plate 93 above the spline connection head. The rotating shaft 911 of the blade extends in the vertical direction. The end surface of the power output shaft 921 of the ro...

Embodiment 3

[0047] Embodiment three, the difference with embodiment two is:

[0048] see Figure 6 , one end of the heat conduction sleeve 734 and one end of the heat sink 71 are sealed against the sealing plate 74 , that is, both the heat conduction sleeve and the heat sink can slide relative to the seal plate 74 . The other end of the heat conducting sleeve 734 and the other end of the radiator 71 are sealed and connected together through the annular liquid storage bag 75 . The annular liquid storage bag 75 is filled with heat-insulating liquid, and the heat-insulating liquid makes the annular liquid storage bag 75 in an elastically expanded state. When the temperature is below 25° C., a sealed cavity 76 is formed among the heat conducting sleeve 734 , the sealing plate 74 , the radiator 71 and the annular liquid storage bag 75 . The sealed cavity 76 communicates with the annular liquid storage bag 75 .

[0049] When in use, the annular liquid storage bag 75 is positioned above the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com