Electronic component auxiliary mounting structure

A technology for mounting structures and electronic components, applied in electrical components, electrical components, etc., can solve problems such as low work efficiency, narrow application range, circuit board damage, etc., to achieve the effect of improving convenience and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034]In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

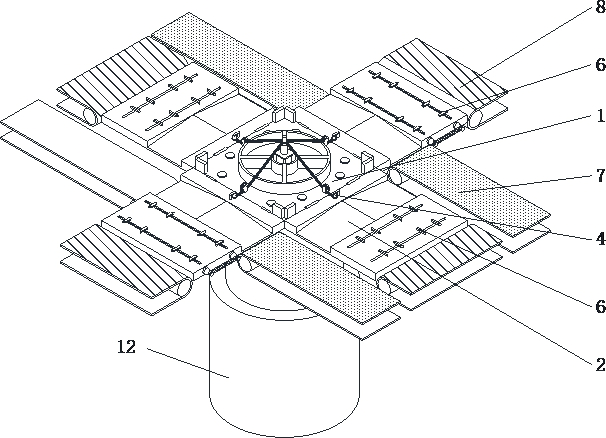

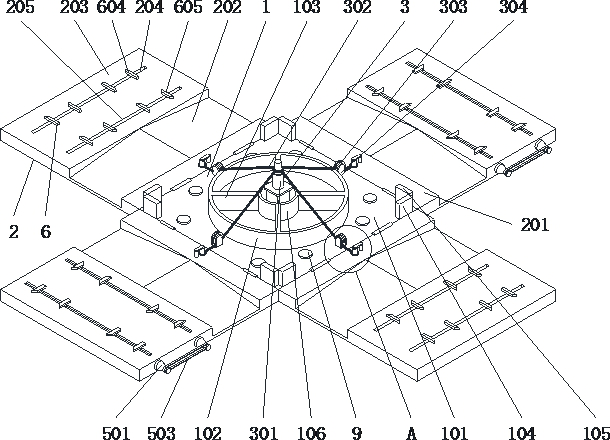

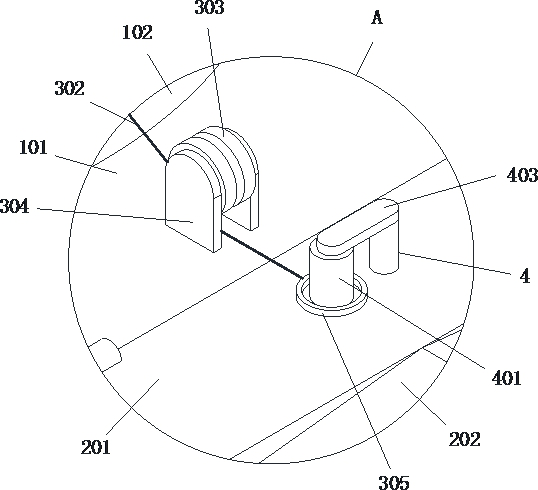

[0035] Such as Figure 1-7 As shown, an auxiliary installation structure for electronic components includes a support assembly 1, a discharge conveyor belt 7, a feed conveyor belt 8, a mechanical arm rocker shaft support 9 and an electric push rod 12, so as to adapt to the discharge conveyor belt 7 and the height of the feed conveyor belt 8 are used, and the surrounding rotation of the support assembly 1 is equipped with a feeding assembly 2. During the forward movement of the feed conveyor belt 8, the feeding assembly 2 enables the device to pass through the feed conveyor belt. 8 Squeeze the circuit board into the surface of the feeding assembly 2 of the device to facilitate subsequent automatic fixing of the circuit board. The bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com