Realizing method and device of coal slime semi-concentrate flotation process

A realization method and technology of coal slime water, applied in the field of flotation, can solve the problems of small equipment selection, difficult control of process parameters, frequent fluctuations, etc., reduce investment costs and processing costs, ensure separation process indicators, and flotation chemicals consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

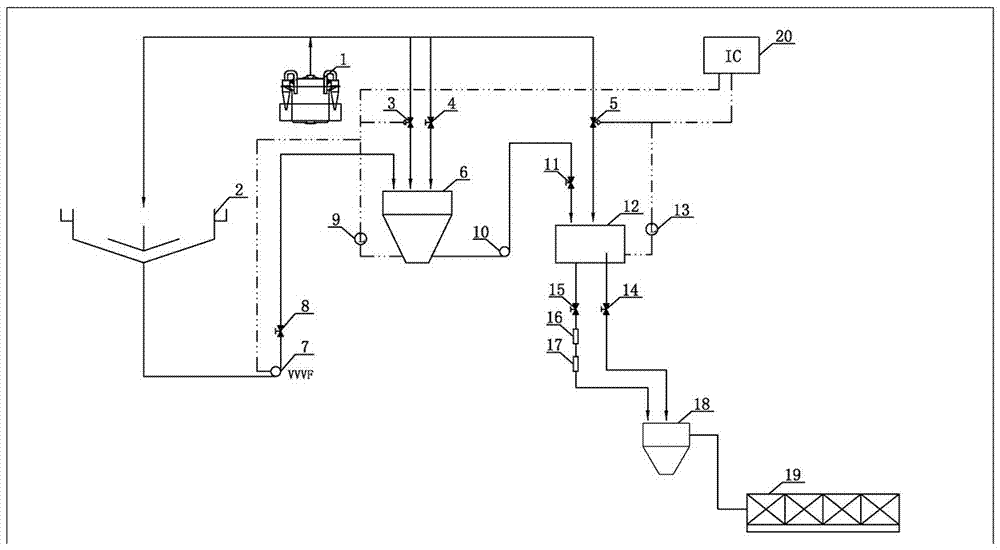

[0036] Attached below figure 1 The present invention is further described, but they are not intended to limit the protection scope of the present invention.

[0037] Such as figure 1As shown, the device for realizing the semi-concentrated flotation process of coal slime water in this embodiment includes a thickener (2), a first electric regulating valve (3), a first manual regulating valve (4), a second electric regulating valve ( 5), slurry mixing bucket (6), underflow pump (7), second manual control valve (8), first static pressure sensor (9), transfer pump (10), third manual control valve (11) , mixing tank (12), second static pressure sensor (13), fourth manual regulating valve (14), fifth manual regulating valve (15), concentration meter (16), flow meter (17), pulp pretreatment device (18), flotation machine (19), intelligent controller (20).

[0038] The working principle and working process of the device for realizing the semi-concentrated flotation process of coal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com