Zein-chitosan composite agglomerate and multi-mode ultrasonic preparation method

A technology of zein and complex coagulation, which is applied in food science and other fields, can solve the problems of poor coagulation effect and low embedding efficiency of bioactive components, and achieve the effects of long release time, increased added value and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

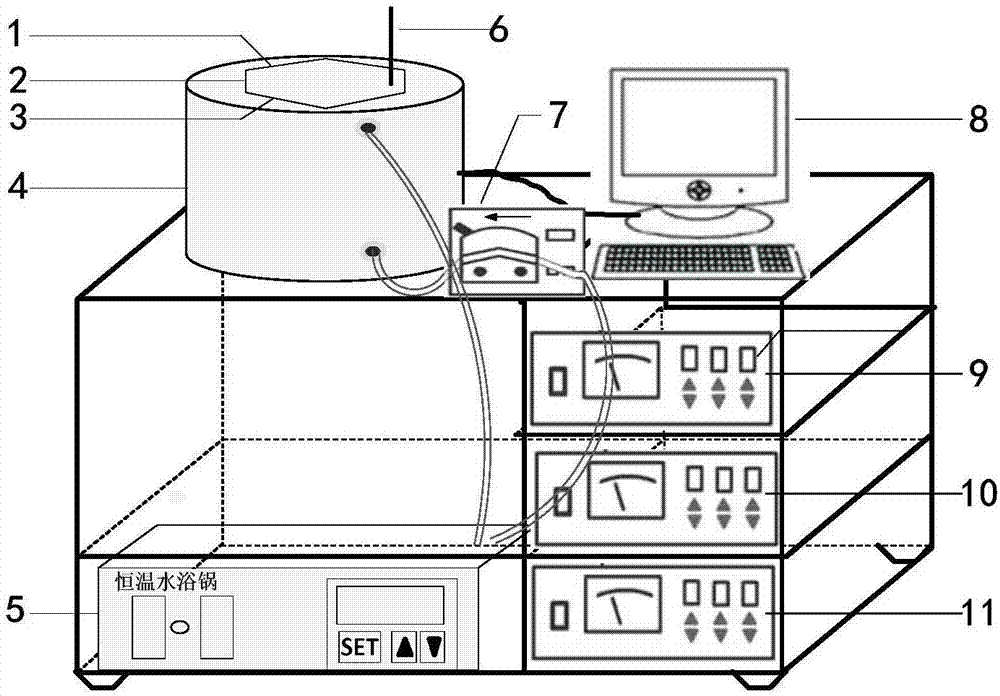

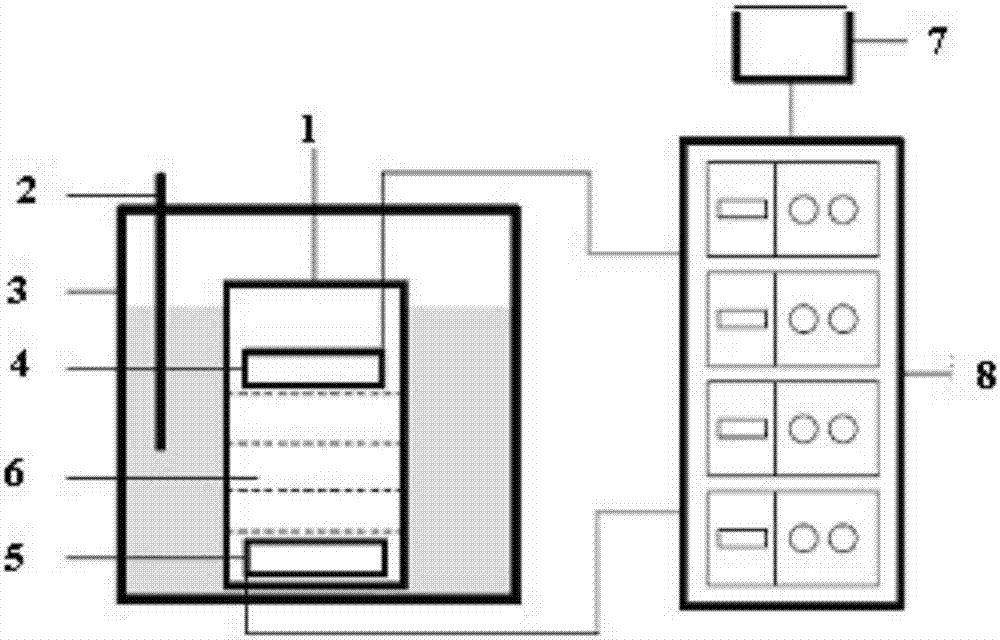

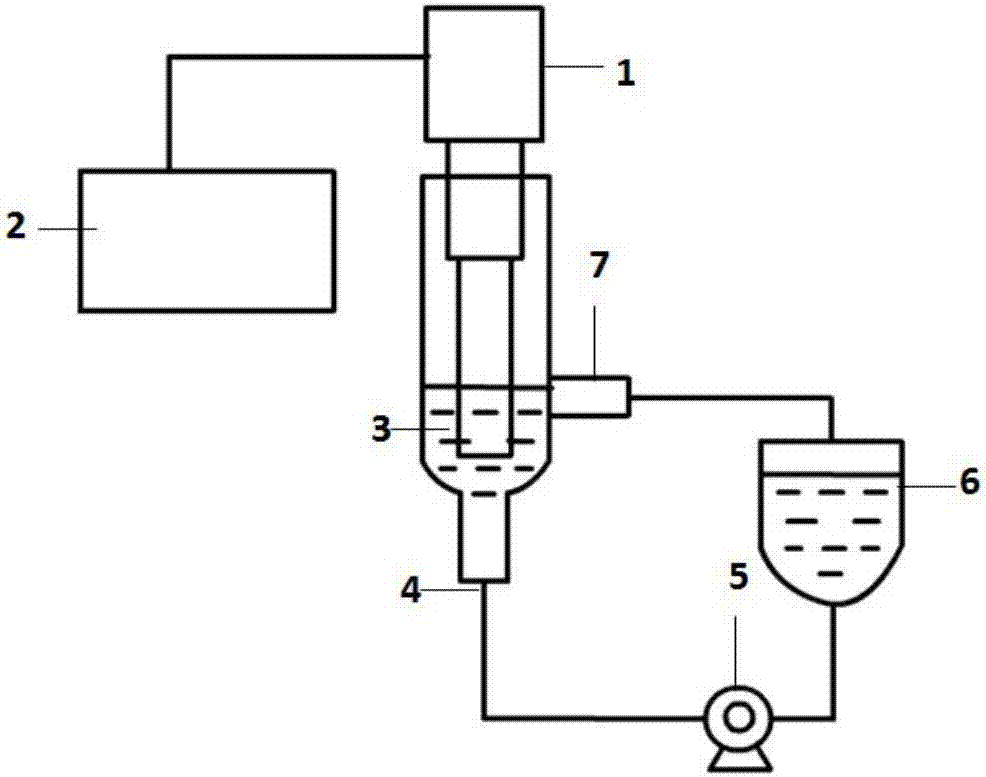

Method used

Image

Examples

Embodiment 1-6

[0053] Embodiment 1-6 (do not add ultrasonic)

[0054] The ratio of zein and chitosan is shown in Table 1, and the molecular weight of chitosan is 100,000 Daltons.

[0055] The zein-chitosan complex aggregate is prepared according to the following steps:

[0056] (1) Dissolve zein in 70% ethanol to obtain a solution with a zein concentration of 0.06 g / mL, stir magnetically until completely dissolved; centrifuge at low temperature (4°C) for 10 min at 8000 r / min; take 0.75 mL Supernatant, disperse dropwise into 2mL deionized water under the condition of vortex shaking;

[0057] (2) Add resveratrol into the above mixed solution under the condition of avoiding light, so that the mass ratio of zein and resveratrol is 10:1.

[0058] (3) Chitosan is put into the above-mentioned mixed solution according to a certain ratio, and the mass ratio of zein and chitosan is shown in Table 1.

[0059] (4) Stand still at room temperature for 6 hours to obtain the zein-chitosan complex coacerv...

Embodiment 7-10

[0067] Embodiment 7-10 (add ultrasonic)

[0068] Zein: 1 part;

[0069] Chitosan: 1 part, the molecular weight of chitosan is 100,000 Daltons.

[0070] The zein-chitosan complex aggregate is prepared according to the following steps:

[0071] (1) Dissolve zein in 70% ethanol to obtain a solution with a zein concentration of 0.06 g / mL, stir magnetically until completely dissolved; centrifuge at low temperature (4°C) for 10 min at 8000 r / min; take 0.75 mL Supernatant, disperse dropwise into 2mL deionized water under the condition of vortex shaking;

[0072] (2) Add resveratrol into the above mixed solution under the condition of avoiding light, so that the mass ratio of zein and resveratrol is 10:1.

[0073] (3) Put chitosan into the above mixed solution in a certain proportion, the mass ratio of zein and chitosan is 1:1.

[0074](4) Simultaneously perform multi-frequency mode ultrasonic treatment under light-proof conditions, wherein the multi-frequency ultrasonic treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com