Mechanical automation vegetable planting system

A planting system and vegetable technology, applied to motor vehicles, climate change adaptation, rack railways, etc., can solve the problems of easy corrosion and damage of nozzles, waste of labor, waste, etc., to improve work efficiency, reduce labor intensity, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

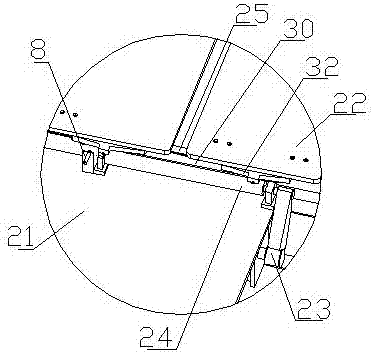

[0019] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a planting shed, a mobile planting frame, a mobile irrigation manipulator and a planting pot transfer vehicle, the planting shed includes a room frame 41, a sunshade device and a spraying device, and the top of the room frame 41 is provided with There is a transparent plastic film 42, and the sunshade device includes a sun visor mounting seat 43, a pair of telescopic sun visors 44 and a pair of electric slides 45, the sun visor mounting seat 43 is installed at the center of the housing body frame 41 top, and a pair of telescopic sun visors One end of the plate 44 is installed on both sides of the sun visor mounting seat 43 respectively, a pair of electric slides 45 are installed on the room body frame 41, and the other end of a pair of telescopic sun visors 44 is installed on the sides of a pair of electric slides 45 respectively. On the slide block, the spraying device includes one group of water pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com