A kinetically adjustable color-changing material and its preparation method

A technology of acidity regulator and indicator, which is applied in the field of color-changing indicator technology and related materials, which can solve the problems of poor dynamic adjustable range, single color change, high cost, etc., and achieve the effect of small volume, relatively small volume and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0131] Using the following recipe and procedure, a self-evolving color-changing indicator was prepared.

[0132] formula:

[0133]

[0134] Note 1: The standard concentration of gold nanorod solution is prepared by dispersing gold nanorods in cetyltrimethylammonium chloride solution (0.010M), its extinction peaks are at 508nm and 825nm, and the optical density at 508nm 10.000cm -1 , the optical density at 825nm is 44.000cm -1 . The same below.

[0135]Note 2: The standard concentration of silver chloride suspension is obtained by mixing equal masses of cetyltrimethylammonium chloride solution (concentration: 0.116M) and silver nitrate (concentration: 0.100M) solution. The same below.

[0136] operate:

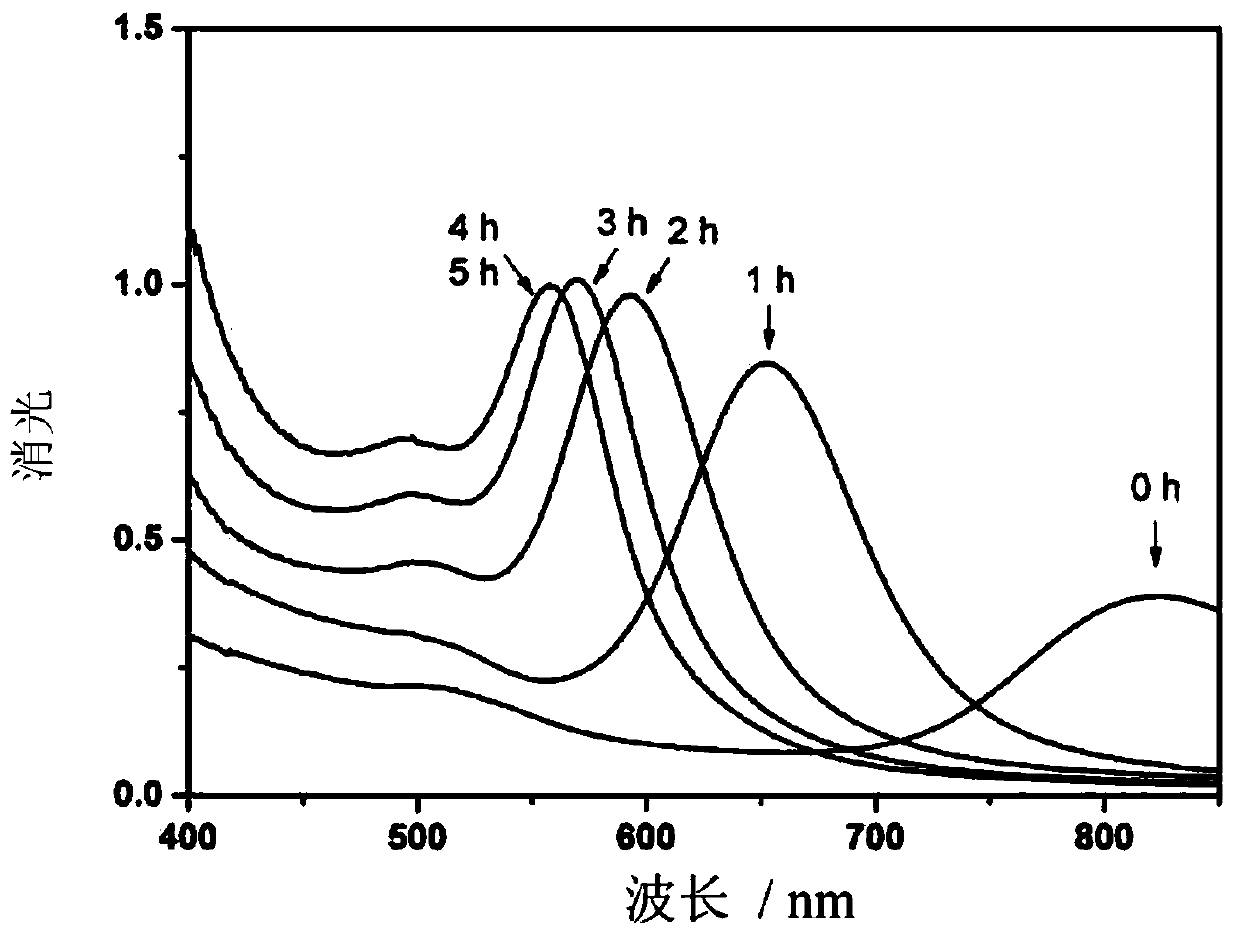

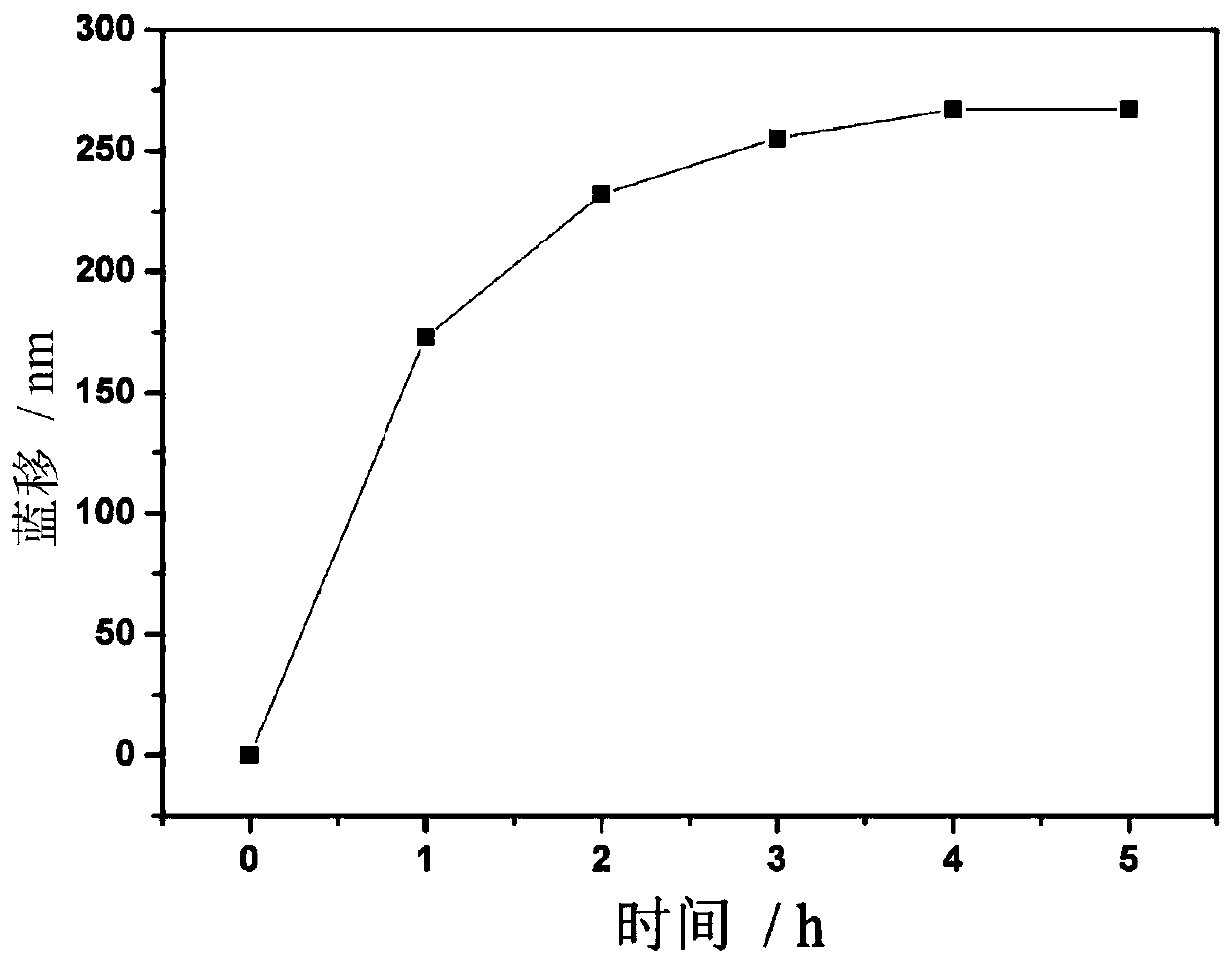

[0137] 1) At a reaction temperature of 35°C, gold nanorod solution (standard concentration, 0.4000g), cetyltrimethylammonium chloride (0.100M, 0.5000g), cetyltrimethylammonium bromide (0.001M, 0.4000g) and ascorbic acid (0.100M, 0.1000g) were fully mixed to obtain a c...

Embodiment 2

[0143] Using the same recipe and operation as in Example 1, the self-evolving color indicator was prepared at a reaction temperature of 5°C.

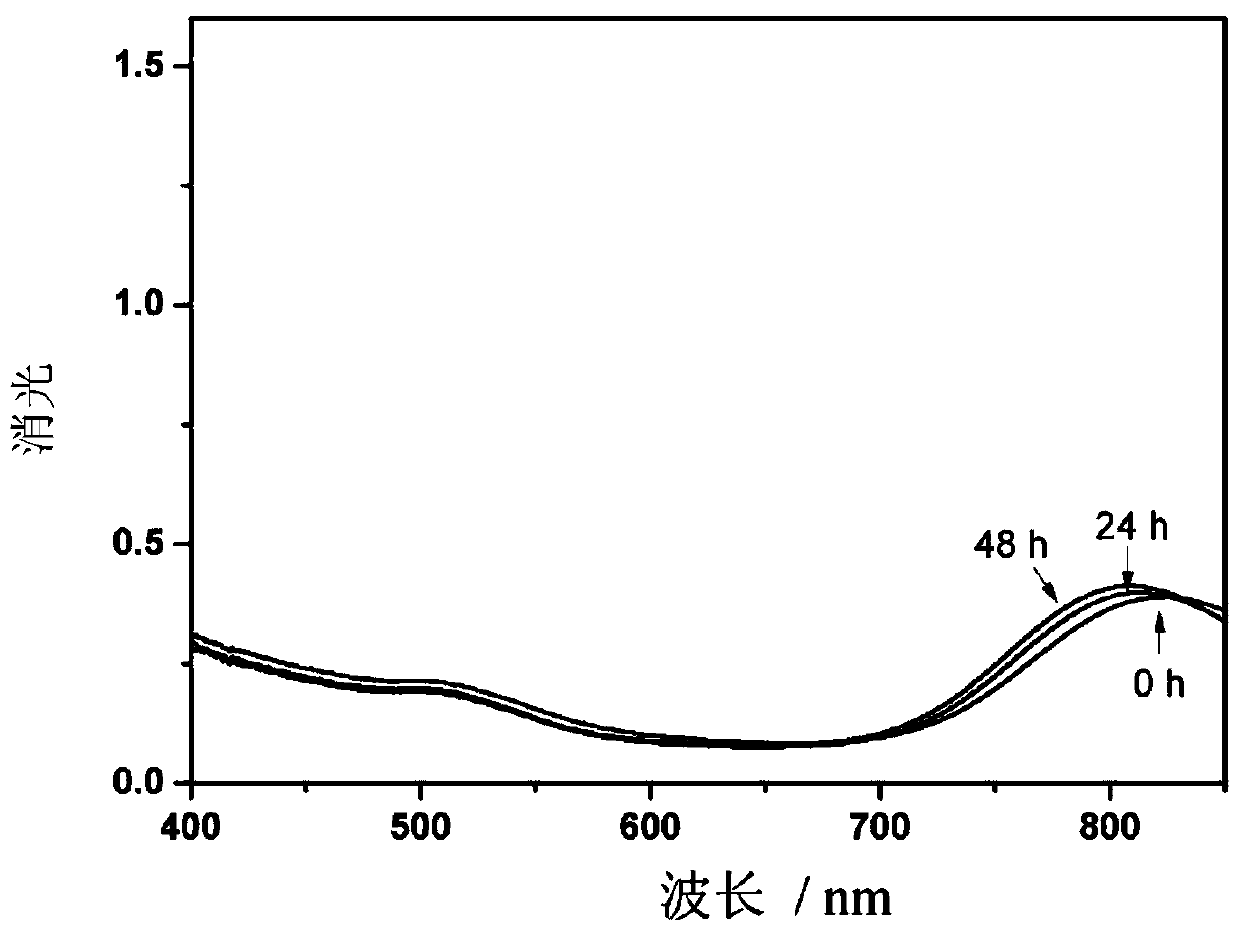

[0144] Place the prepared self-evolving color indicator in a constant temperature environment at 5°C, and measure its extinction spectrum every 24 hours. The results are as follows: Figure 2A and 2B shown.

[0145] It can be known from the spectral results that, compared with Example 1, when the ambient temperature decreases (from 35° C. to 5° C.), the self-evolving color-changing process of the self-evolving color-changing indicator slows down.

Embodiment 3

[0147] Using the following recipe and the same operation as in Example 1, a self-evolving color indicator was prepared.

[0148] formula:

[0149]

[0150] Place the prepared self-evolving color indicator in a constant temperature environment of 35°C, measure its extinction spectrum every 1.0h, and the results are as follows: Figure 3A and 3B shown.

[0151] It can be seen from the spectral results that, compared with Example 1, when the concentration of ascorbic acid is reduced (the amount used is reduced from 0.1000 g to 0.0500 g), the self-evolving color-changing process of the self-evolving color-changing indicator slows down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com