Discoloration indicator for shelf life of perishable product and preparation method thereof

An indicator and perishable technology, applied in the field of color-changing indicator technology and related materials, can solve the problems of difficult to completely cover, high cost, public health and safety threats, etc., and achieve the effect of safe preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Silver nitrate solution (0.1M, 30μL) was added to CTAC solution (0.08M, 1mL), followed by AA solution (1M, 3mL), gold nanorod solution (1mL, the maximum extinction peak was 870nm, and the optical density was 3cm -1 ), sodium acetate solution (0.1M, 50 μL). Place the mixed solution in a 30°C incubator, such as figure 1 As shown, the extinction spectrum of the solution changes, the maximum extinction peak gradually shifts to blue, and the solution changes from red to green within 1 hour.

Embodiment 2

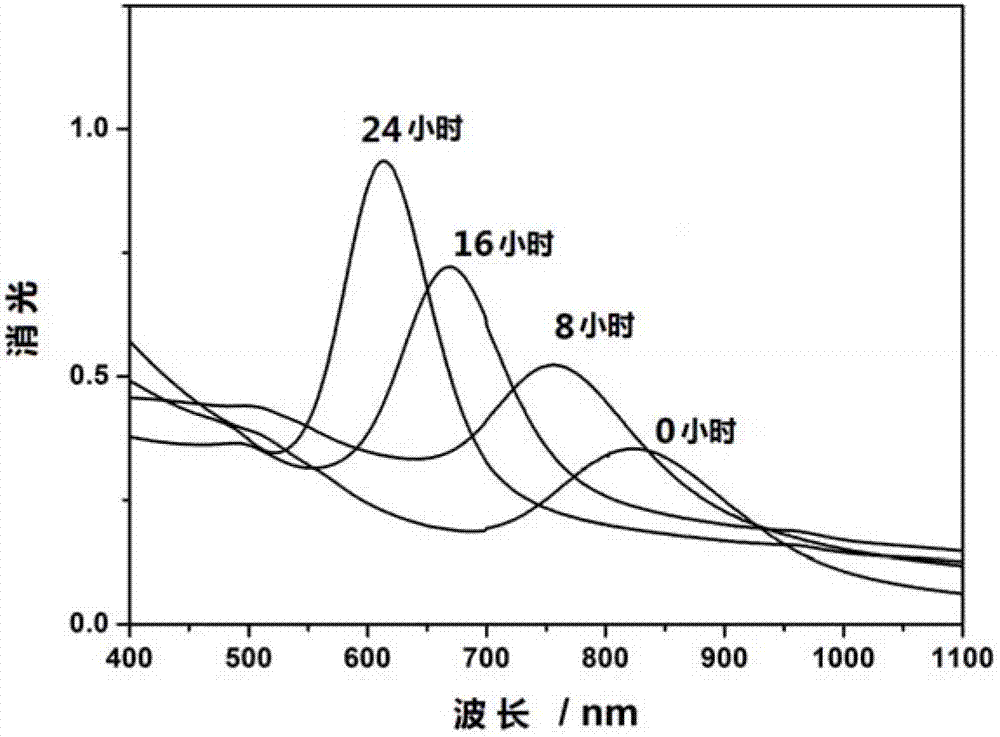

[0044] Silver nitrate solution (0.1M, 30 μL) was added to CTAC solution (0.08M, 1mL), followed by AA solution (0.1M, 3mL), gold nanorod solution (1mL, the maximum extinction peak position was 870nm, and the optical density was 3cm -1 ), acetic acid solution (0.1M, 50 μL). Place the mixed solution in a 30°C incubator, such as figure 2 As shown, the extinction spectrum of the solution changes, the maximum extinction peak gradually shifts to blue, and the solution changes from red to green within 24 hours.

Embodiment 3

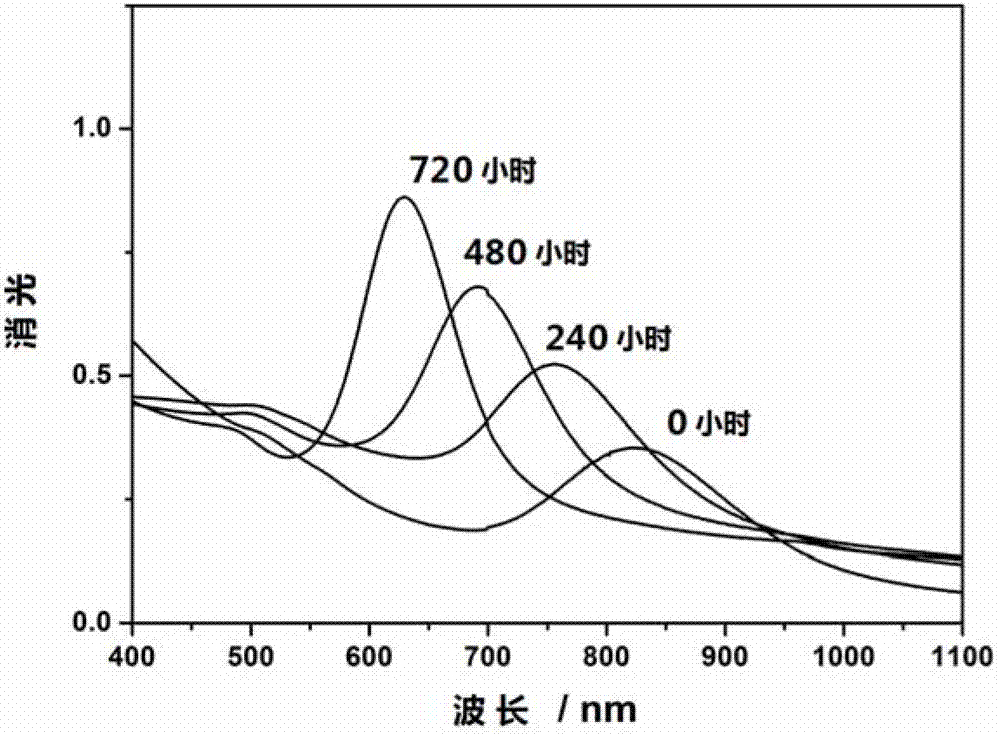

[0046] Silver nitrate solution (0.1M, 30 μL) was added to CTAC solution (0.08M, 1mL), followed by ascorbic acid solution (0.1M, 3mL), gold nanorod solution (1mL, the maximum extinction peak position was 870nm, and the optical density was 3cm -1 ), acetic acid solution (0.1M, 5mL). Place the mixed solution in a 30°C incubator, such as image 3 As shown, the extinction spectrum of the solution changes, the maximum extinction peak gradually shifts to blue, and the solution changes from red to green within 720 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com