Automobile headlamp based on laser excitation of fluorescence optical fiber

A technology for exciting fluorescence and fluorescent optical fibers, which is applied to optical components used to change the spectral characteristics of emitted light, headlights, and semiconductor devices for light-emitting components. , to achieve the effects of compact structure, easy access to laser modules, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

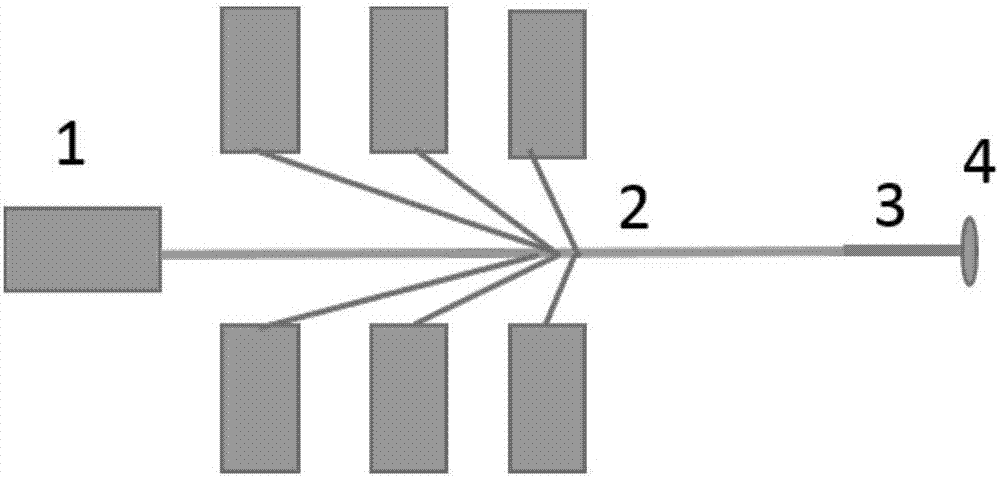

[0024] figure 1 A schematic diagram of the structure of a laser-excited fluorescent fiber optic automotive headlight is given, as shown in figure 1 shown. Including: a laser module 1, used to emit laser light; an optical fiber 2, connected to the laser module 1, used to transmit the laser light emitted by the laser module 1; a fluorescent optical fiber 3, connected to the optical fiber 2; specifically , in this embodiment, after the laser module 1 emits laser light, the laser light is transmitted to the fluorescent optical fiber 3 through the optical fiber 2, and the laser light will excite the fluorescent optical fiber to generate a white light beam visible to human eyes. The white light beam is expanded through the lens 4 at the end of the optical fiber to generate parallel light, which results in a smaller emission angle, thereby increasing the overall irradiation distance of the vehicle light.

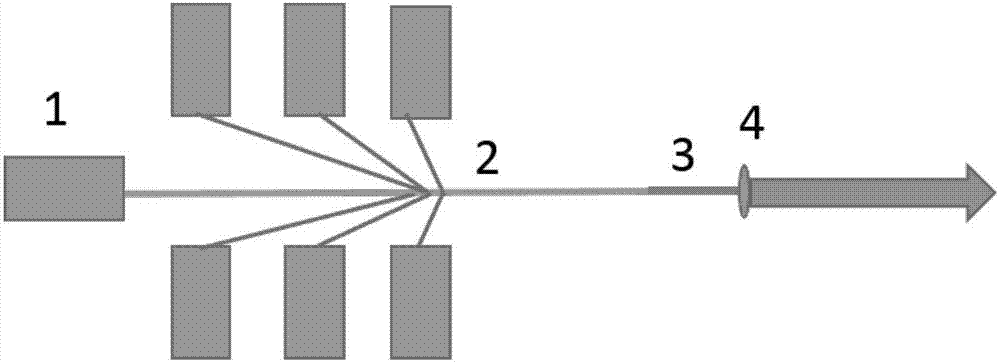

[0025] figure 2 A schematic diagram of the use state of a fiber-optic lase...

Embodiment 2

[0028] In this embodiment, multiple lasers are arranged in the laser module 1, and the laser light emitted by the lasers is coupled through the optical fiber 2, so as to increase the power of the laser. As the power of the laser is increased, the power of the laser injected into the fluorescent optical fiber 3 is also increased, and the power of the light in the red, yellow and green segments generated by the laser irradiation is also enhanced, and the power of the formed white light beam is also enhanced. The white light beam is expanded through the lens 4 at the end of the fluorescent optical fiber 3 to generate parallel light, which obtains a smaller emission angle and realizes the purpose of remote irradiation of vehicle lights.

[0029] Tests have shown that the laser-excited fluorescent optical fiber automotive headlight of the present invention has a longer irradiation distance. Compared with traditional LED headlights, the light transmission of the car light proposed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com