Mechanical hand used for grabbing disc parts

A technology of manipulator and grabbing plate, applied in the field of robotics, can solve the problems of high labor cost, large market demand, low product value, etc., and achieve the effect of high degree of automation, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

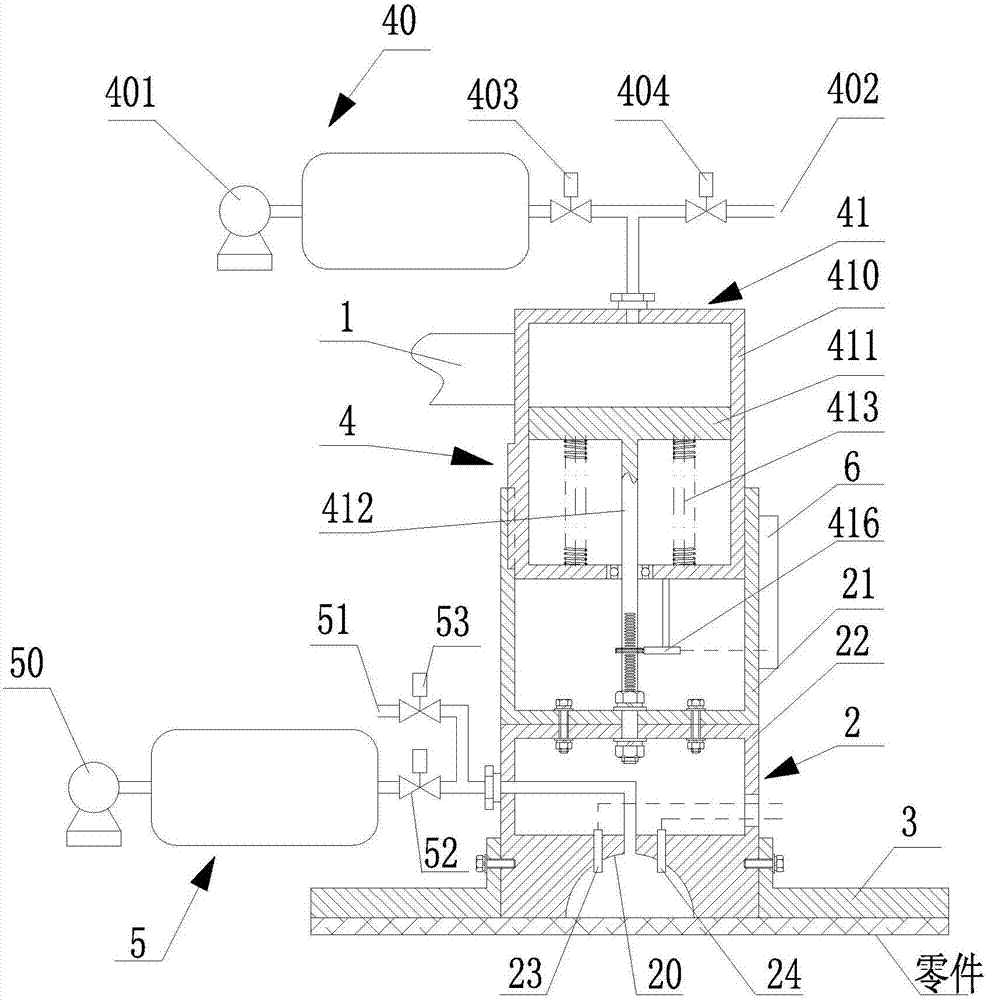

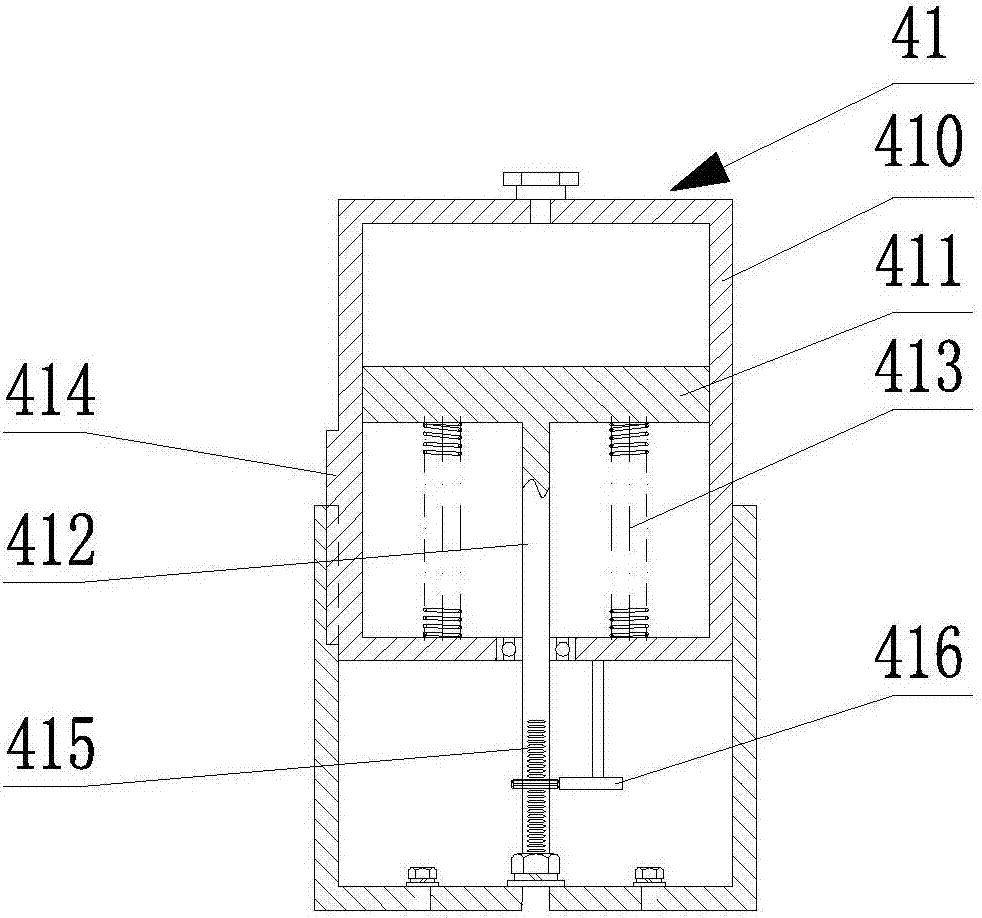

[0029] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a manipulator for grasping disc parts. The manipulator is mounted on the manipulator 1 , and the manipulator includes a support device 2 , a mold 3 , a drive device 4 , an adsorption device 5 and a controller 6 .

[0030] A groove 20 is provided at the bottom of the support device 2, and the groove 20 can form a sealed vacuum adsorption area with the parts. The mold 3 is arranged on the support device 2, and the bottom surface of the mold 3 and the bottom surface of the support device 2 are located on the same horizontal plane.

[0031] The upper part of the driving device 4 is connected with the mechanical arm 1, the bottom of the driving device 4 is connected with the supporting device 2, and the driving device 4 drives the supporting device 2 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com