Preparation method of raw whole potato powder

A kind of raw potato powder and potato technology, applied in food science, food preservation, application, etc., can solve food safety problems, poor browning inhibition effect, etc., to achieve the purpose of inhibiting non-enzymatic browning, retaining nutrients, and improving protection color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

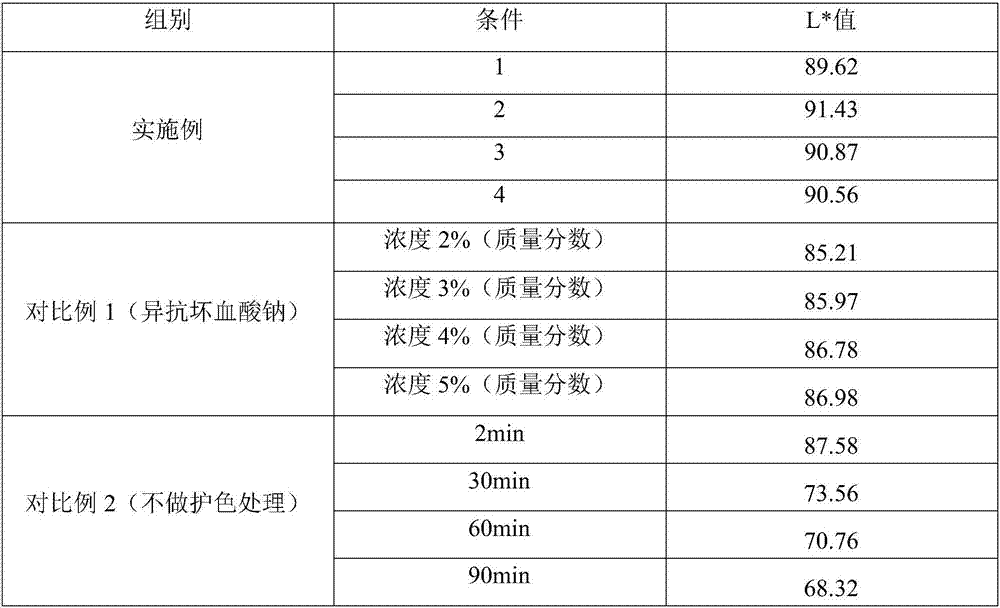

Examples

Embodiment 1

[0033] A preparation method of raw potato powder, comprising the following steps:

[0034] (1) Raw material selection: use Yu Potato No. 1 as the raw material, and select potatoes with few buds, no rot and no pests;

[0035] (2) Cleaning: the potatoes are cleaned with a potato cleaning machine, and the temperature of the cleaning water is 15°C; after cleaning, the potatoes are sorted again, and rotten, germinated and green-skinned potatoes are selected;

[0036] (3) peeling: the potato of step (2) is removed epidermis with potato peeling machine;

[0037] (4) slice: the potato of step (3) is cut into the sheet that thickness is 5mm with machine;

[0038] (5) soaking in white vinegar: soak the potato slices in step (4) with a white vinegar solution with a mass fraction of 1.0% for 20 min;

[0039] (6) Cleaning: Rinse the potato chips in step (5) with clear water, the temperature of the cleaning water is 15°C, and drain the water after cleaning;

[0040] (7) Ultra-high pressu...

Embodiment 2

[0044] A preparation method of raw potato powder, comprising the following steps:

[0045] (1) Raw material selection: use Luo Potato No. 8 as the raw material, and select potatoes with few buds, no rotten deterioration and no insect damage;

[0046] (2) Cleaning: clean the potatoes with a potato cleaning machine, and the temperature of the cleaning water is 20°C; after cleaning, the potatoes are sorted again, and the rotten, germinated and green-skinned potatoes are selected;

[0047] (3) peeling: the potato of step (2) is removed epidermis with potato peeling machine;

[0048] (4) Cut into strips: the potato of step (3) is cut into the strip of 1 * 1 * 5cm with machine;

[0049] (5) soaking in white vinegar: soak the potato strips in step (4) with a white vinegar solution with a mass fraction of 1.5% for 20 min;

[0050] (6) Cleaning: rinse the potato strips in step (5) with clear water, the temperature of the cleaning water is at 20°C, and drain the water after cleaning;

...

Embodiment 3

[0055] A preparation method of raw potato powder, comprising the following steps:

[0056] (1) Raw material selection: use Shang Potato No. 1 as the raw material, and select potatoes with few buds, no rot and no pests;

[0057] (2) Cleaning: clean the potatoes with a potato cleaning machine, and the temperature of the cleaning water is 20°C; after cleaning, the potatoes are sorted again, and the rotten, germinated and green-skinned potatoes are selected;

[0058] (3) peeling: the potato of step (2) is removed epidermis with potato peeling machine;

[0059] (4) dicing: the potato of step (3) is cut into pieces of 1 * 1 * 1cm by machine;

[0060] (5) soaking in white vinegar: soak the potato pieces in step (4) with a white vinegar solution with a mass fraction of 1.5% for 20 min;

[0061] (6) Cleaning: Rinse the potato pieces in step (5) with clear water, the temperature of the cleaning water is at 20°C, and drain the water after cleaning;

[0062] (7) Ultra-high pressure tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com