Compact antenna feed calibration network

An antenna feeding and antenna calibration technology, which is applied in the field of feeding calibration comprehensive network design, can solve the problems of calibration network amplitude-phase consistency variation, mutual crosstalk of antenna signals, and antenna influence on electrical performance, etc., and achieve good amplitude-phase consistency , reduce the thickness of the section, the structure is simple and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

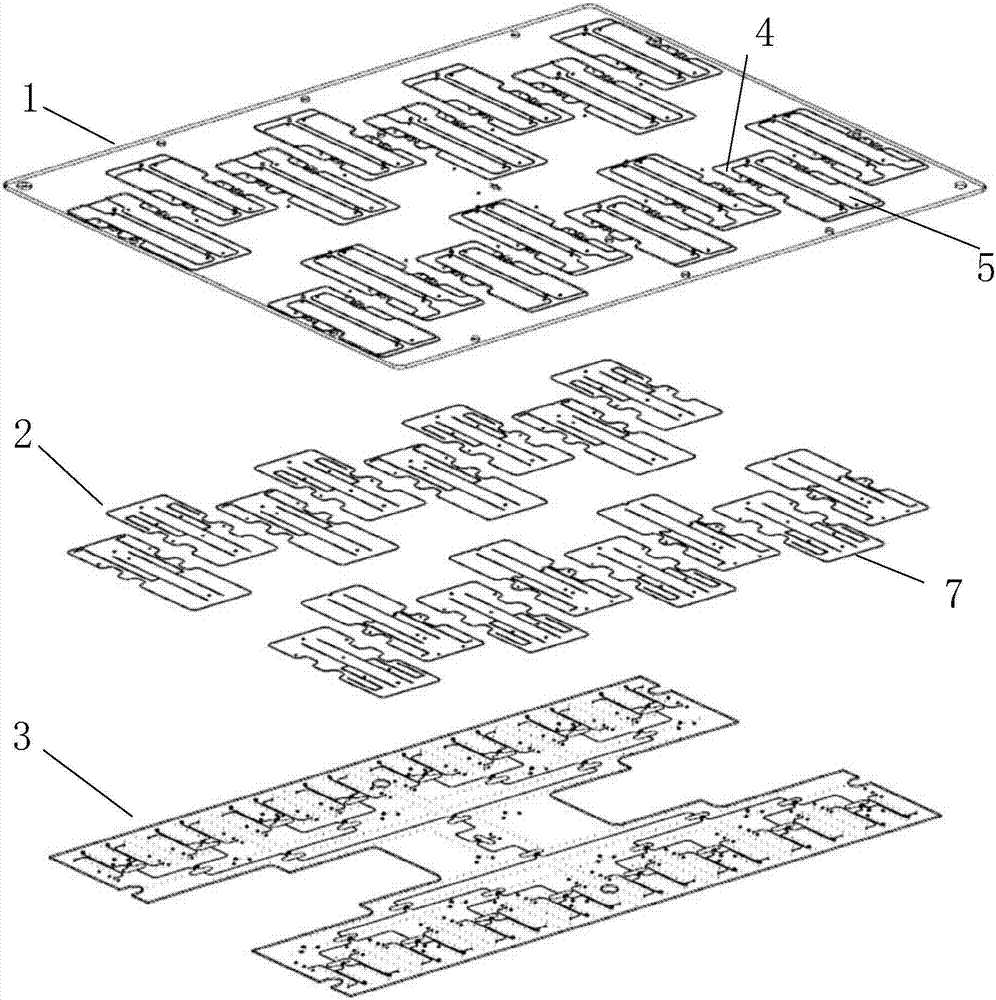

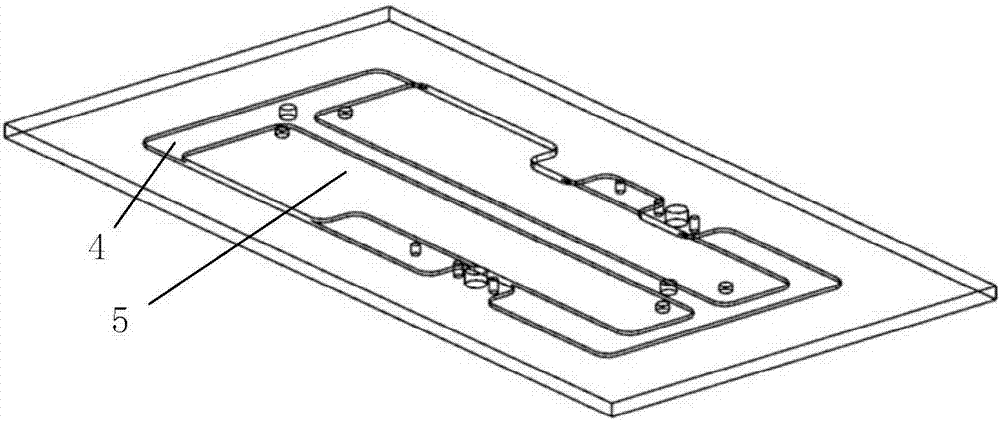

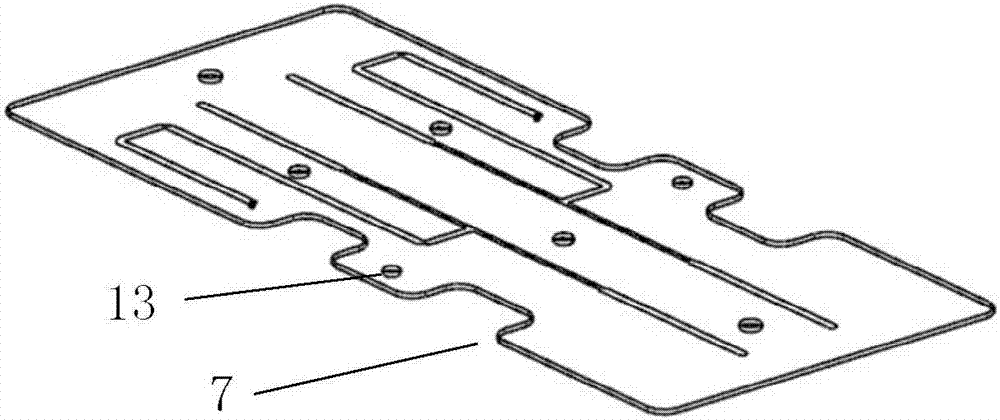

[0023] refer to figure 1 . An antenna feeding calibration network described in the embodiment of the present invention mainly includes three parts: the upper antenna metal floor 1 , the middle antenna combiner feeding network 2 and the lower antenna calibration network 3 . The upper antenna metal floor 1, the middle antenna combiner feed network 2 and the lower antenna calibration network 3 with a symmetrical structure, the upper antenna metal floor 1 is the top layer, and the upper antenna metal floor 1 is equipped with the corresponding middle antenna combiner feed network 2 The embedding grooves of each combiner module 7 are staggered at the same interval to bury each combiner module 7 in the metal floor. The combiner is installed in blocks, and each two-unit sub-array The two combiners required for polarization are used as a module, and are fastened together with the upper antenna metal floor 1 in the form of block installation to form the feed network of the middle anten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com