A kind of cable support mechanism and cable platform

A technology of support mechanism and support line, which is applied in opto-mechanical equipment, microlithography exposure equipment, instruments, etc., can solve the problems of collision and friction between cables and the basic frame, cable stuck, unable to adapt to cables, etc. Control positioning accuracy, optimize support effect, and small sag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

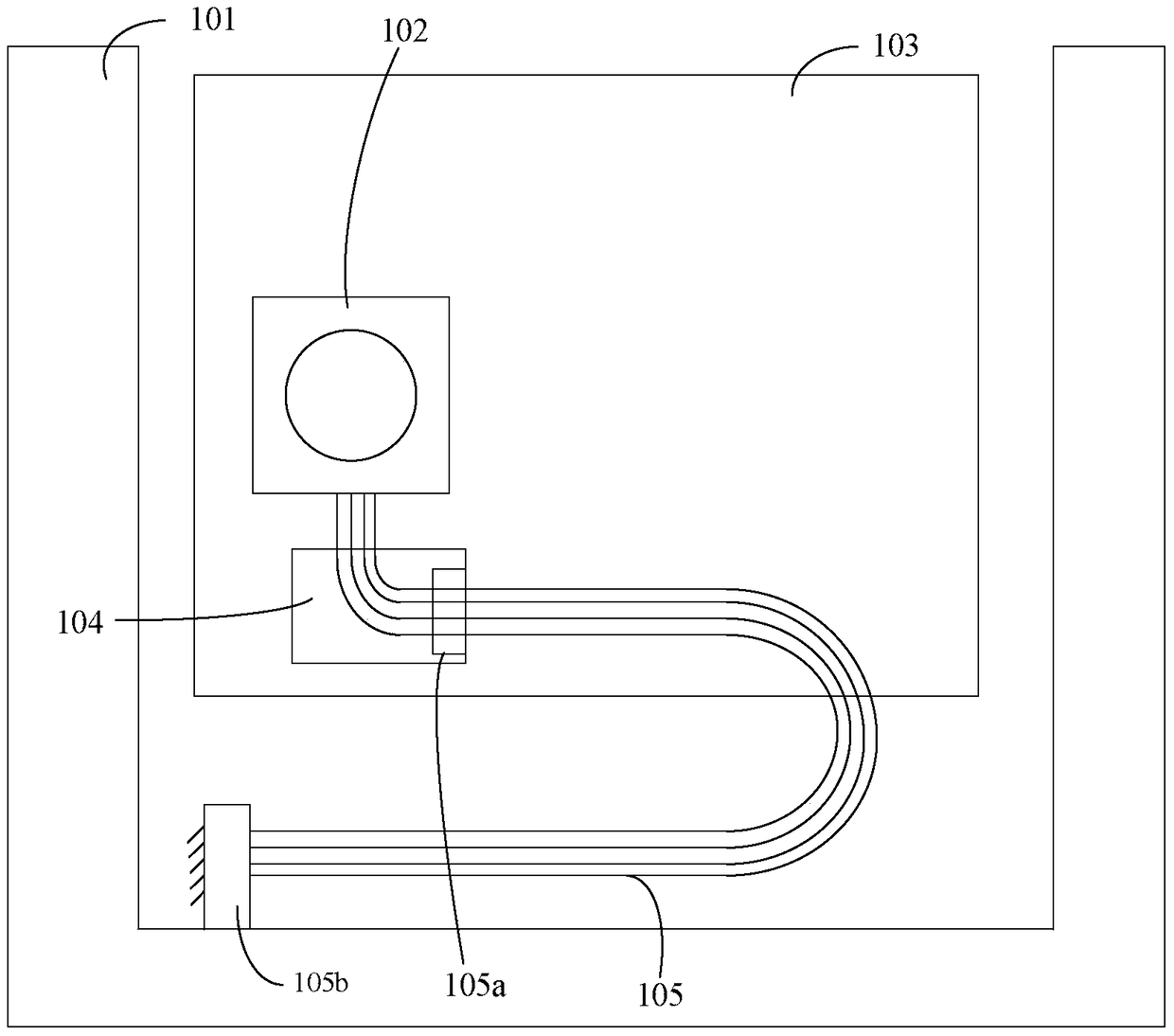

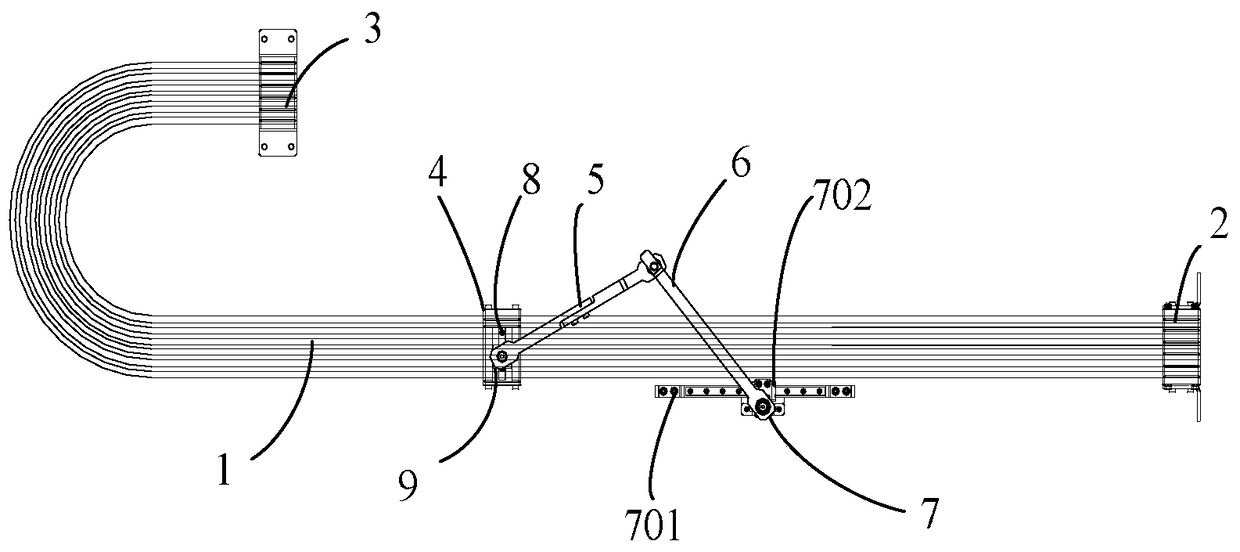

[0037] Such as Figure 2-5b As shown, the present invention provides a cable support mechanism for supporting the gravity of the U-shaped cable 1, the U-shaped cable 1 includes 3 layers of cables and 3 layers of pipes arranged in the horizontal direction, figure 2Every two lines form a layer of cables or pipes. One end of the U-shaped cable 1 is fixed on the basic frame (not shown in the figure) through the fixed end clamp 2, and the other end is connected to the cable platform through the movable end clamp 3. (not shown in the figure) is connected and moves together with the cable table.

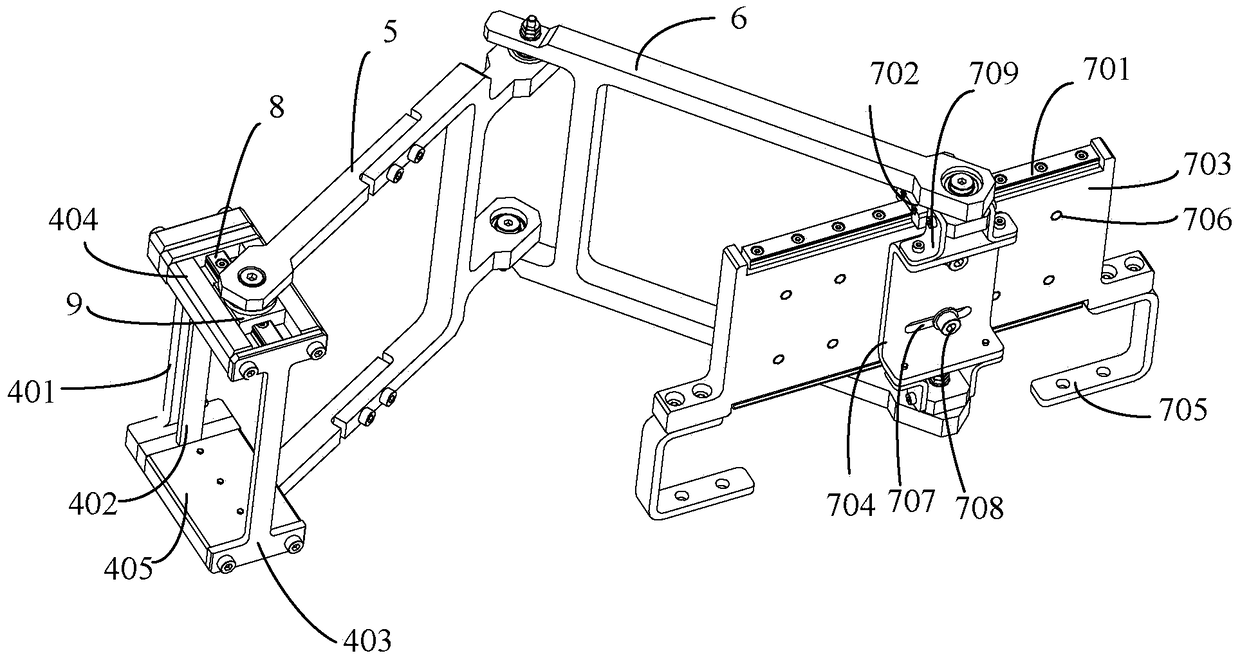

[0038] Please refer to figure 2 , the cable support mechanism includes a support clamp 4, a first link 5, a second link 6 and an adjustable connector 7, the U-shaped cable 1 passes through the support clamp 4, and the support clamp 4. Clamp the innermost layer of cables or tubes of the U-shaped cable, and only support the other 5 layers of cables or tubes. Since the movement trajectorie...

Embodiment 2

[0055] Such as Figure 6 As shown, different from Embodiment 1, in this embodiment, one end of one connecting rod in the first connecting rod 5 is connected to the top support plate 404, and one end of the other connecting rod is connected to the bottom The support plate 405 is connected, the first connecting rod 5 and the top support plate 404, the first connecting rod 5 and the bottom support plate 405 are all connected by a rotating pair, and the two connecting rods of the first connecting rod 5 The other end is provided with a first support rail 8, the first support rail 8 is affixed to the first connecting rod 5, and the first support slider 9 is slidably provided on the first support rail 8, and the first support slider 9 9 is connected with one end of the second connecting rod 6, and the first supporting slider 9 is connected with the second connecting rod 6 by a rotary pair. Adopting the above setting method can save the installation space of the cable support mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com