High-precision mirror surface automatic detection equipment and working method thereof

An automatic detection, high-precision technology, applied in the direction of cleaning methods using tools, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of increasing capital and labor costs, affecting life, mirror damage, etc., and achieve practical savings and manpower, improve accuracy, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

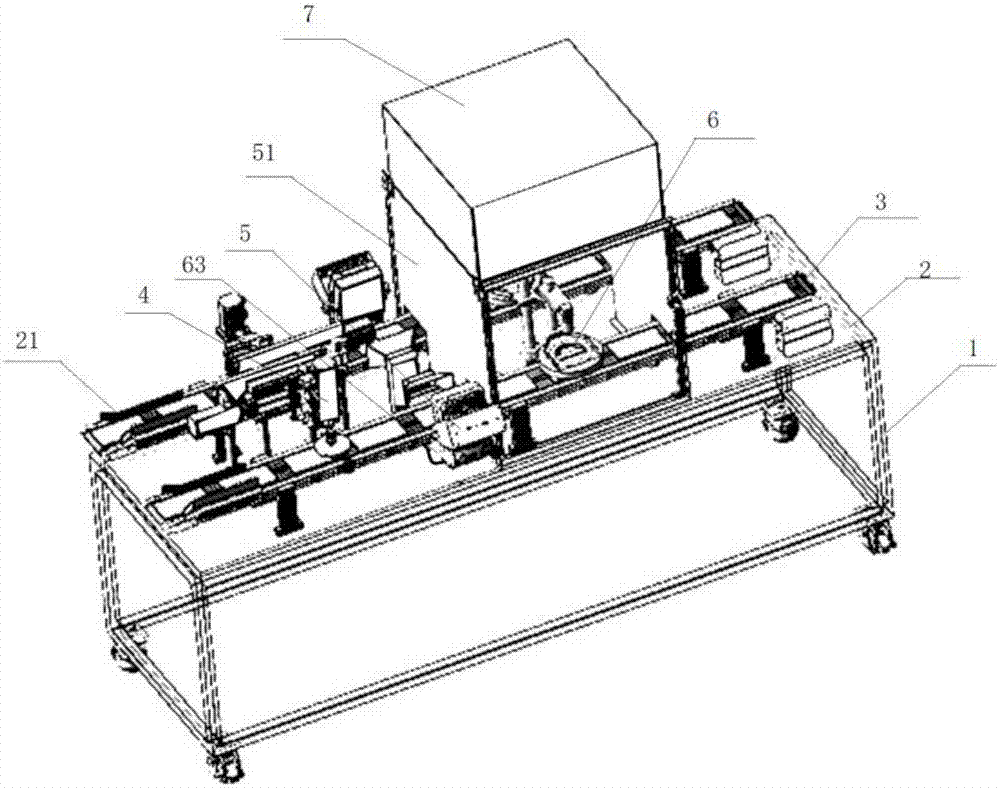

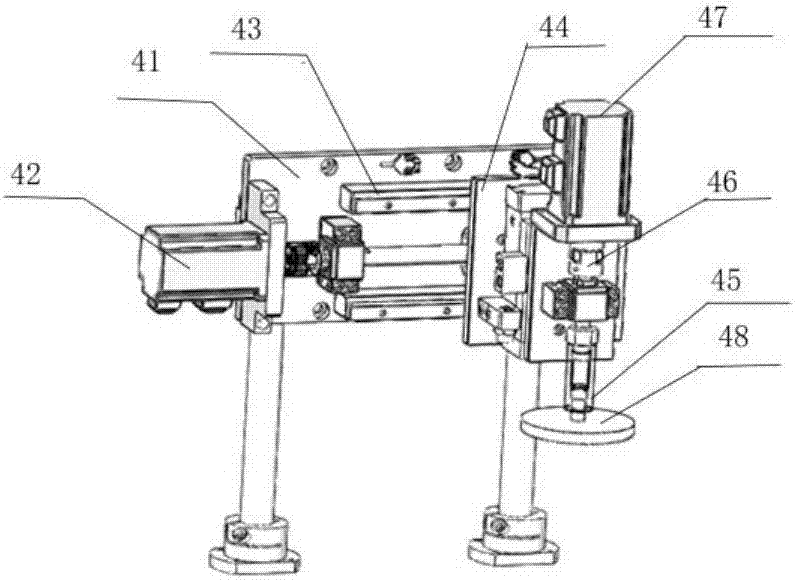

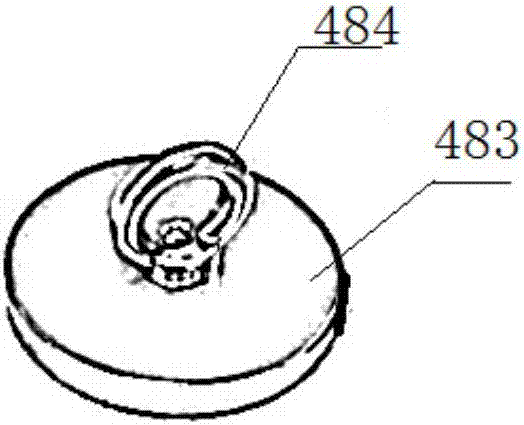

[0059] Such as Figure 1 to Figure 4 , Figure 9 , 10 A high-precision mirror automatic detection device shown includes: a body 1, a workbench 2, a dust removal device 4, a fan 5, a detection device 6 and a control device;

[0060] The relationship between the above components is as follows:

[0061] The workbench 2 is provided with a detection streamline 3, and the front and rear of the detection streamline 3 are respectively provided with a feed inlet and a discharge port, and a first station 31 and a second station 31 are arranged on the streamline. 32 and the third station 33; the dust removal device 4 is arranged on the first station 31, the fan 5 is arranged on the second station 32, the detection device 6 is arranged on the third station 33, and An air cleaner 7 is arranged above the detection device 6, and the dust removal device 4, the fan 5, the detection device 6 and the air cleaner 7 are all connected to the control device.

[0062] In this embodiment, the dust...

Embodiment 2

[0076] Such as Figure 5-8 as well as Figure 11 , 12 A high-precision mirror automatic detection device shown includes: a body 1, a workbench 2, a dust removal device 4, a fan 5, a detection device 6, a cleaning mechanism 8 and a control device;

[0077] The relationship between the above components is as follows:

[0078]The workbench 2 is provided with a detection streamline 3, and the front and rear of the detection streamline 3 are respectively provided with a feed inlet and a discharge port, and a first station 31 and a second station 31 are arranged on the streamline. 32 and the third station 33; the dust removal device 4 is arranged on the first station 31, the fan 5 is arranged on the second station 32, the detection device 6 is arranged on the third station 33, and , the top of the detection device 6 is provided with an air cleaner 7, the cleaning mechanism 8 is located at the first station 31, the dust removal device 4, the fan 5, the detection device 6, the air ...

Embodiment 3

[0094] Such as Figure 5-8 as well as Figure 11 , 12 A high-precision mirror automatic detection device shown includes: a body 1, a workbench 2, a dust removal device 4, a fan 5, a detection device 6, a cleaning mechanism 8 and a control device;

[0095] The relationship between the above components is as follows:

[0096] The workbench 2 is provided with a detection streamline 3, and the front and rear of the detection streamline 3 are respectively provided with a feed inlet and a discharge port, and a first station 31 and a second station 31 are arranged on the streamline. 32 and the third station 33; the dust removal device 4 is arranged on the first station 31, the fan 5 is arranged on the second station 32, the detection device 6 is arranged on the third station 33, and , the top of the detection device 6 is provided with an air cleaner 7, the cleaning mechanism 8 is located at the first station 31, the dust removal device 4, the fan 5, the detection device 6, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com