Mechanical type end surface sealing specific pressure measuring device for high-speed liquid oxygen turbine pump

A technology of end face sealing and turbo pump, which is used in liquid/vacuum measurement for liquid tightness, and by measuring the acceleration and deceleration rate of fluid, etc., which can solve the problems that the seal cannot be actually measured, and the pressure and rise of the seal cavity cannot be effectively controlled. , to avoid the influence of friction, improve the accuracy of measurement, and eliminate the effect of unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

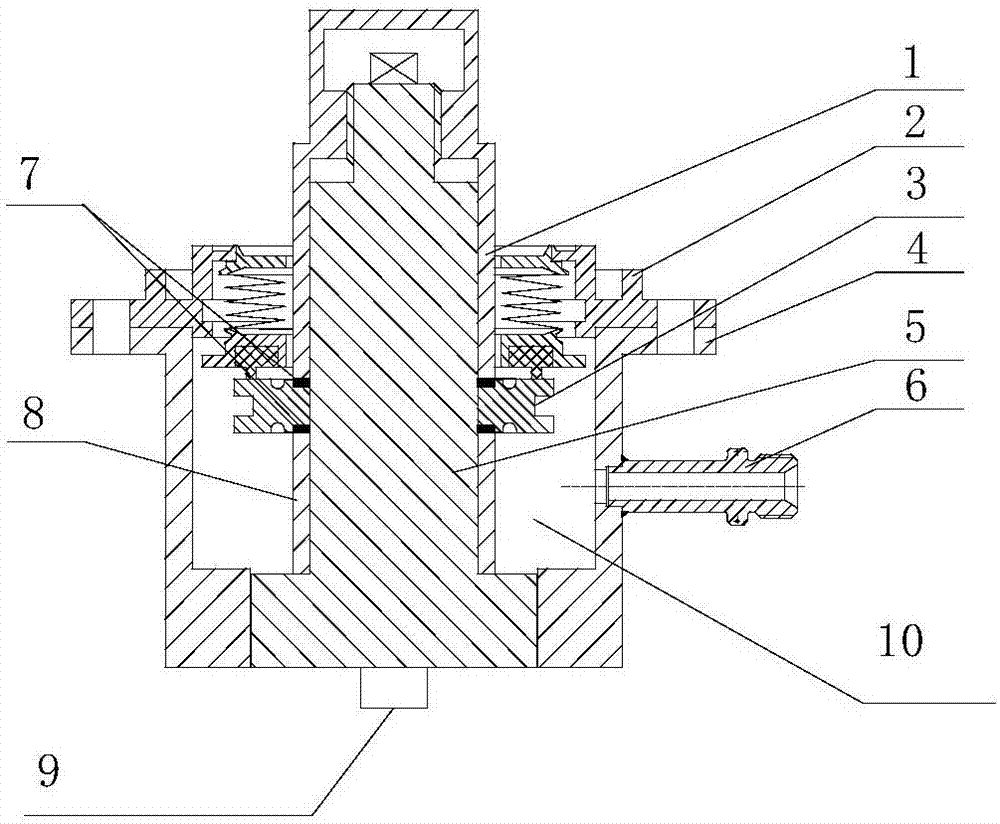

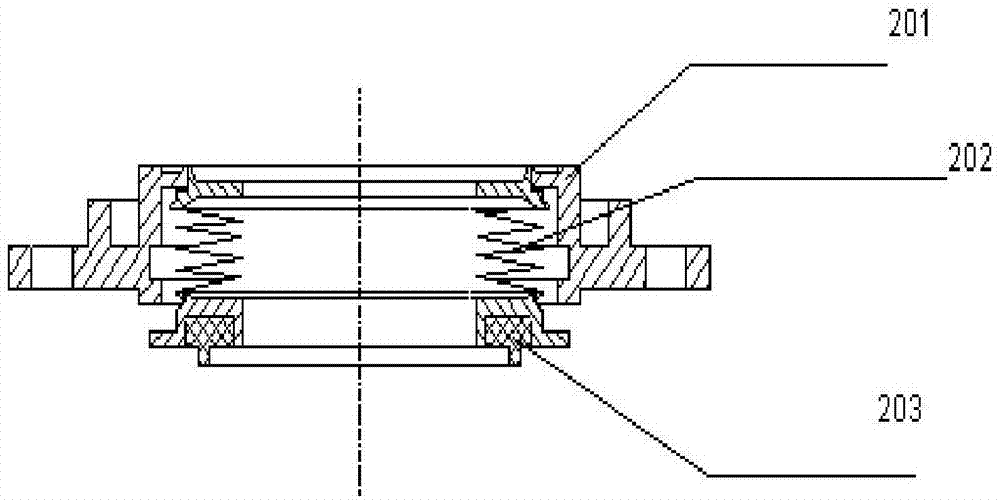

[0020] Such as figure 1 The present invention shown includes a sealed static ring assembly 2, a moving ring 3, a first shaft sleeve 1, a housing 4, a shaft 5, a charging nozzle 6, a sealing gasket 7, a second shaft sleeve 8, and a pressure sensor 9, wherein the shaft 5 is a two-stage structure, including the shaft part of the thin section and the piston part of the thick section. The first shaft sleeve 1 and the second shaft sleeve 8 are respectively sleeved on the shaft body part from the upper part and the lower part. The first shaft The connection between the sleeve 1 and the second sleeve 8 is fixedly connected with the moving ring 3 through the gasket 7, the sealing static ring 2 assembly is fixed on the first sleeve 1, and the upper end of the moving ring 3 is in close contact with the sealing static ring assembly 2, The upper end of the casing 4 is fixedly connected with the sealing static ring assembly 2, the lower end of the casing 4 is connected with the piston part,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com