Non-contact freely-locatable method for measuring deformation of cylinder

A measurement method and a technology for positioning cylinders, which are applied in the direction of mechanical solid deformation measurement, etc., can solve the problems that the engine cannot be measured, and achieve the effect of convenient and free clamping and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

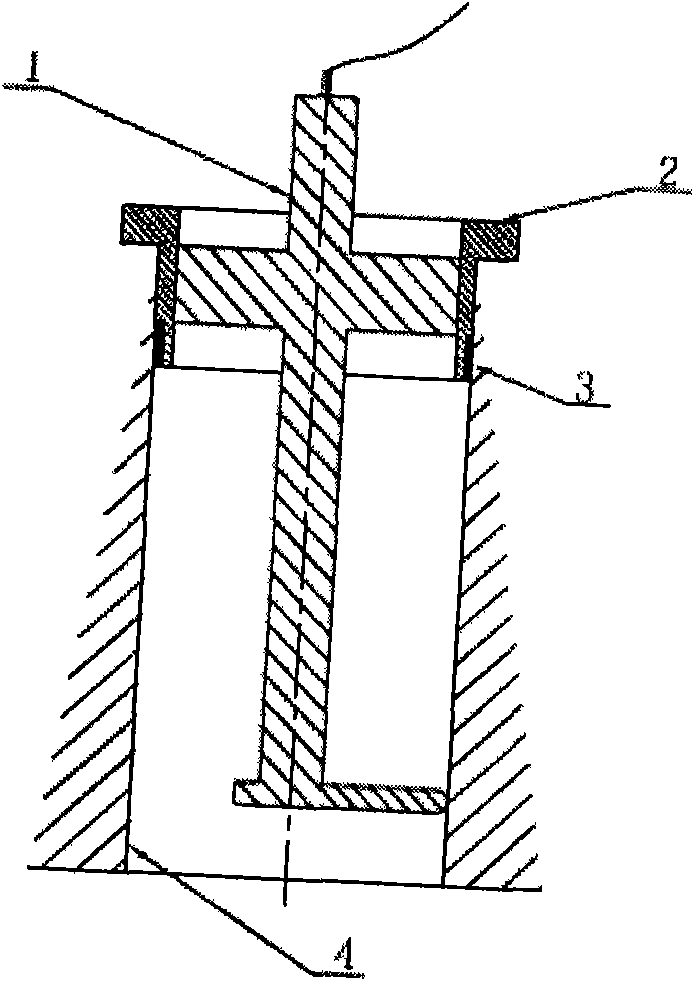

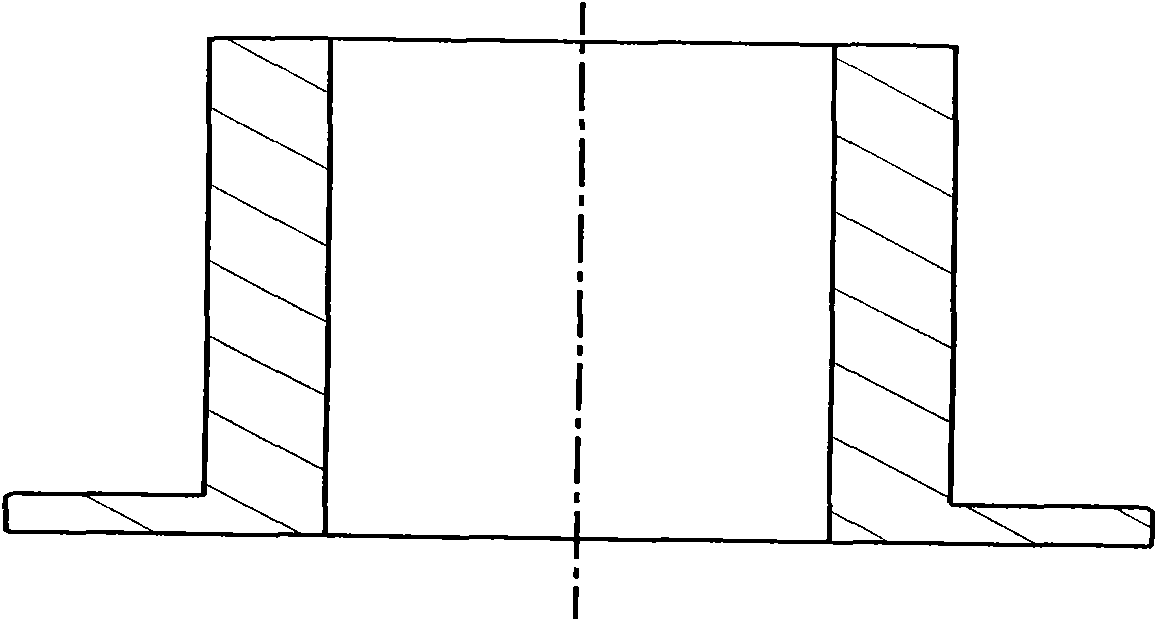

[0008] The following structural drawings further describe the present invention: as Figure 1-2 As shown, the non-contact free positioning cylinder deformation measurement method is characterized in that: the cylinder deformation T-shaped fixture 2 is set on the cylinder 4, so that the upper part of the T-shaped fixture 2 rests on the edge of the cylinder 4, and the lower part goes deep into the cylinder. In cylinder 4, fixture 2 is put into the cylinder barrel 4 and pasted with elastic soft medium 3, the width of the medium is about 8-12 mm, and fixture 2 pasted with soft medium 3 is put into engine cylinder barrel 4, so that the inner wall of cylinder barrel 4 Position with the outer edge of the soft medium 3; after positioning, the probe 1 is directly clamped into the cylinder deformation fixture; after the probe 1 is clamped, the probe 1 is concentric with the cylinder 4 and then the measurement starts. Because the positioning of the cylinder itself is currently used, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com