Method for preparing polyvinyl acetate zirconyl precursor sol spinning solution and sub-micron zirconium oxide crystal fibers

A technology of sol spinning solution and precursor fiber, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of low solid content of precursor spinning solution, insufficient diameter of zirconia crystal fiber, and It is difficult to guarantee the spinnability and fiber crystal quality at the same time, so as to achieve the effect of improving ultra-high temperature thermal insulation and mechanical properties, excellent ultra-high temperature thermal insulation and mechanical properties, and excellent thermal insulation and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of polyzirconyl acetate precursor sol spinning solution:

[0037] Weigh 300g of polyzirconyl acetate, 150g of glacial acetic acid, 45g of yttrium nitrate hexahydrate, and 5g of polyvinylpyrrolidone and dissolve them in 600g of anhydrous methanol under stirring. After the solid was completely dissolved and the reaction solution turned into a transparent solution, it was concentrated under reduced pressure at 35° C. until a colorless and transparent polyzirconyl acetate sol spinning solution with a density of 1.2 g / ml (measured at 25° C.) was obtained.

[0038] (2) Electrospinning

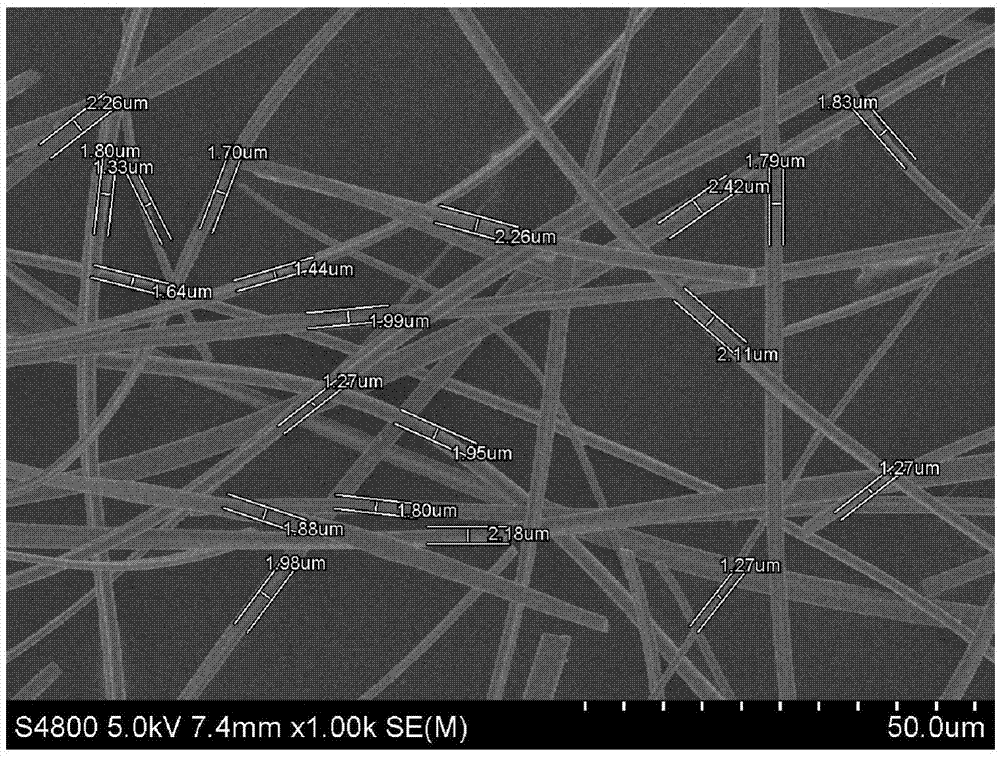

[0039] Add the polyzirconyl acetate sol spinning solution into a glass syringe with a 6# stainless steel needle, propel the spinning solution to flow out slowly by gravity, and cover the negative electrode receiving screen with aluminum foil to collect fibers. At a temperature of 25° C., a humidity of 45%, a voltage of 27 kV, and a receiving distance of 30 cm, the spinning sol...

Embodiment 2

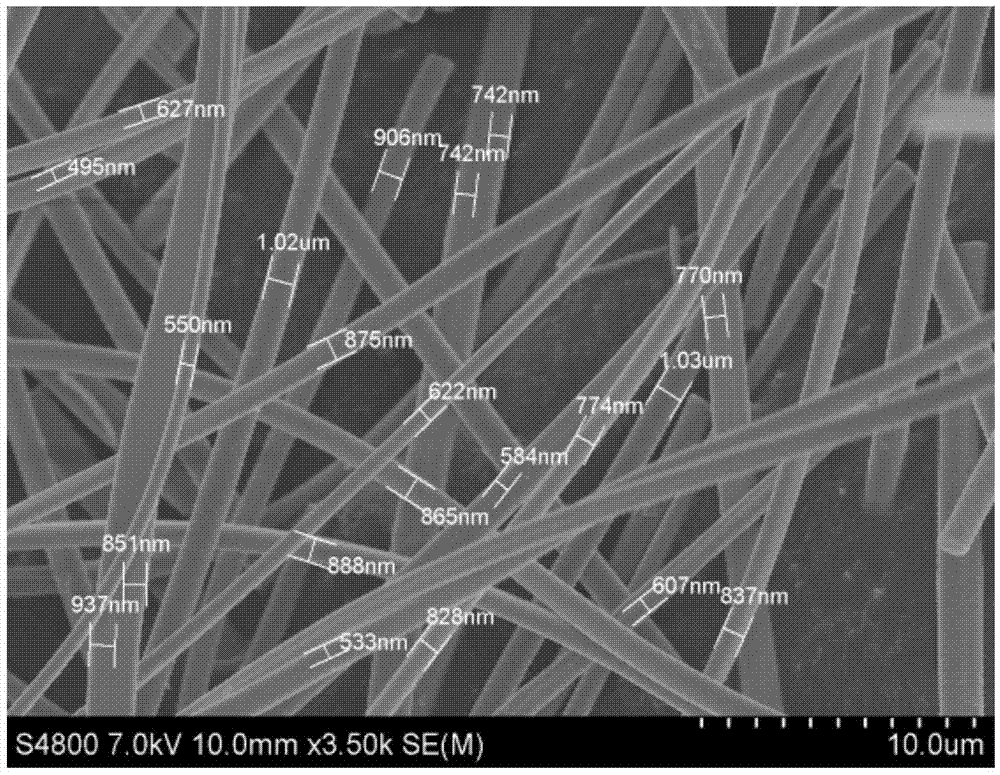

[0045] As described in Example 1, the difference is that step (1) is concentrated under reduced pressure until obtaining a colorless and transparent polyzirconyl acetate spinning solution with a density of 1.08g / ml; in step (2), the stainless steel needle Change to 5#, change the humidity to 60%, and adjust the voltage to 36kV. The diameter of the obtained submicron zirconia crystal fiber is 500nm~1μm, the average diameter is 766nm, and the length is 1~25cm (such as image 3 shown), the contact between grains is close, and the orientation of adjacent grains is relatively consistent (such as Figure 4 shown).

Embodiment 3

[0047] As described in Example 1, the difference is that step (1) concentrates under reduced pressure until obtaining a colorless and transparent polyzirconyl acetate spinning solution with a density of 1.0 g / ml; in step (2), the stainless steel needle Change to 5#, change the humidity to 70%, adjust the voltage to 48kV, and the receiving distance is 25cm. The diameter of the obtained submicron zirconia crystal fiber is 100nm~400nm, the average diameter is 274nm, and the length is 1~12cm ( Figure 5 ), the contact between grains is close, and the orientation of adjacent grains is relatively consistent (such as Image 6 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com