Method for preparing silver nanosheet-modified polyacrylonitrile nano-pillar array film SERS substrate

A nano-pillar array, polyacrylonitrile technology, applied in ion implantation plating, liquid chemical plating, coating and other directions, to achieve the effect of good SERS signal repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

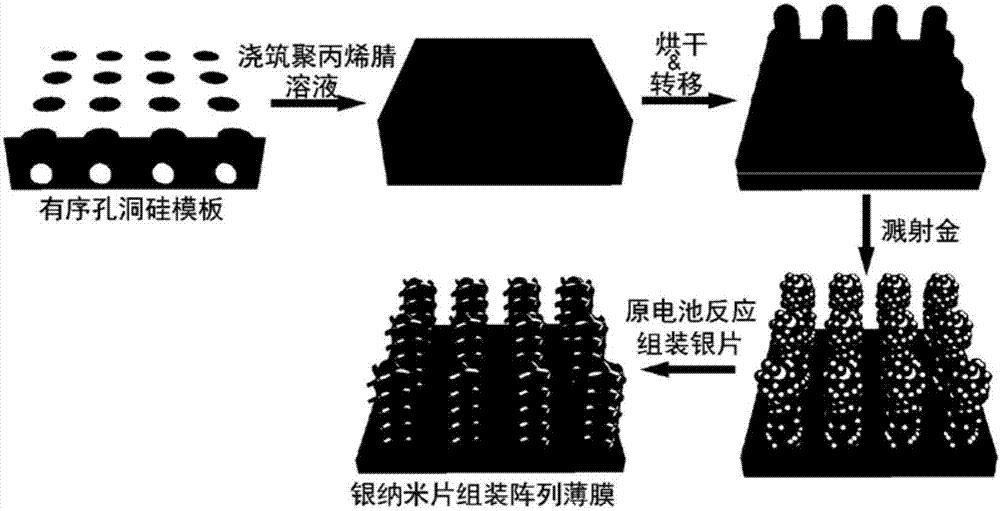

[0028] The preparation method of the polyacrylonitrile nanocolumn array film SERS substrate modified by silver nanosheets of the present invention comprises the following steps:

[0029] (1) First, pour a pre-configured amount (100-400 microliters) of a certain concentration of polyacrylonitrile solution (5%-10% mass fraction, the solvent is N,N'-dimethylformamide) On a silicon template with ordered nano-vertical holes (hexagonal or tetragonal arrangement of holes, period 100nm-1500nm, hole diameter 100nm-800nm, depth 100nm-600nm), and then heat it in an oven (60-80°C) Dry to remove the organic solvent, and after a certain period of time (20-30 minutes), peel off the upper layer of polyacrylonitrile film directly on the surface of the silicon template to obtain a PAN nanocolumn ordered array film;

[0030](2) Using the ion sputtering method, sputtering gold nanoparticles on the surface of the PAN nanocolumn array film obtained in step (1) (2-5 minutes), to obtain the PAN nanoc...

Embodiment 1

[0034] (1) Preparation of PAN nanopillar films: first, a silicon template with nanometer-sized vertical holes arranged in squares on the pre-prepared surface ( figure 2 a-b, period 350nm, diameter 225nm, depth 300nm; silicon template size 2cmx2cm) surface poured 300 microliters of polyacrylonitrile (mass fraction 8%, solvent is dimethylformamide (DMF) solution), and then coated with polyacrylonitrile The silicon template of the acrylonitrile solution was dried in an oven (70°C) to remove the DMF solution. After 25 minutes, a thin film was peeled off on the surface of the silicon template with tweezers to obtain a flexible film of polyacrylonitrile nanopillar arrays. Observation results from SEM ( figure 2 c-d) It can be seen that the surface of the polyacrylonitrile film has a large-area, regularly arranged array of nanocolumns. These nanocolumns are arranged in a uniform tetragonal array. The diameter of the nanocolumns is about 152 nm, and the distance between the centers ...

Embodiment 2

[0042] (1) Preparation of PAN nanopillar films: First, a silicon template with hexagonally arranged nano-vertical holes on the surface ( Figure 9 a-b, pore period 600nm, diameter 400nm, depth 680nm; silicon template size 2cmx2cm) pour 300 microliters of polyacrylonitrile (mass fraction 8%, solvent is dimethylformamide (DMF) solution) on the surface, and then coat the surface with The silicon template of the polyacrylonitrile solution was dried in an oven (70°C) to remove the DMF solution. After 25 minutes, a layer of film was peeled off on the surface of the silicon template with tweezers to obtain a flexible film of polyacrylonitrile nanopillar arrays. Observation results from SEM ( Figure 9 c-d) It can be seen that the surface of the polyacrylonitrile film has a large-area, regularly arranged array of nanopillars. These nanopillars are arranged in a uniform hexagonal array. The diameter of the nanopillars is about 270 nm, and the distance between the centers is about 600 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com