Low-temperature underwater anchoring adhesive and preparation method thereof

A planting glue and low-temperature technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of poor wetting effect of adhesives, slow underwater curing speed, and decline in colloid performance, and achieve good water resistance and water repellency. Water-based, enhanced bonding effect, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of component A: 100 parts by weight of bisphenol A type epoxy resin, 3 parts of reactive diluent, 15 parts of toughening agent, 2 parts of silane coupling agent, and 3 parts of thixotropic agent are mixed Stir well, then add 180 parts of filler and mix well

[0031] Preparation of component B: Mix and stir 94 parts by weight of cardanol-modified phenalkamine curing agent, 6 parts of accelerator, 2 parts of silane coupling agent, and 2 parts of thixotropic agent, and then add 200 parts Stir the filler evenly

[0032] Mix components A and B according to the weight ratio of 2:1 and stir evenly to prepare the low-temperature underwater rebar-planting glue.

Embodiment 2

[0034] Preparation of component A: 100 parts by weight of bisphenol A type epoxy resin, 2 parts of reactive diluent, 16 parts of toughening agent, 3 parts of silane coupling agent, and 2 parts of thixotropic agent are mixed Stir well, then add 200 parts of filler and mix well

[0035] Preparation of component B: Mix and stir 94 parts by weight of cardanol-modified phenalkamine curing agent, 6 parts of accelerator, 2 parts of silane coupling agent, and 3 parts of thixotropic agent, and then add 200 parts Stir the filler evenly

[0036] Mix components A and B according to the weight ratio of 2:1 and stir evenly to prepare the low-temperature underwater rebar-planting glue.

Embodiment 3

[0038] Preparation of component A: 100 parts by weight of bisphenol A type epoxy resin, 3 parts of reactive diluent, 18 parts of toughening agent, 2 parts of silane coupling agent, and 3 parts of thixotropic agent are mixed Stir well, then add 200 parts of filler and mix well

[0039] Preparation of component B: Mix and stir 94 parts by weight of cardanol-modified phenalkamine curing agent, 6 parts of accelerator, 3 parts of silane coupling agent, and 3 parts of thixotropic agent, and then add 220 parts Stir the filler evenly

[0040] Mix components A and B according to the weight ratio of 2:1 and stir evenly to prepare the low-temperature underwater rebar-planting glue.

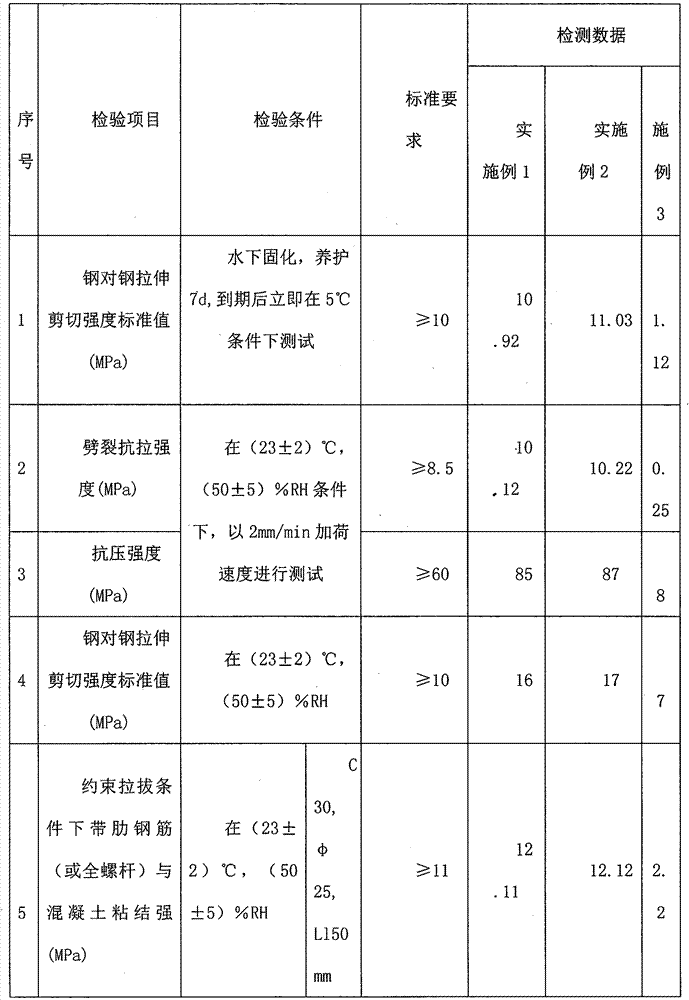

[0041] The performance test of the rebar glue prepared by the three embodiments of the present invention is carried out according to the relevant requirements of GB 50728-2011, and the test data are shown in Attached Table 1

[0042] Table I

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com