Synthesis method and application of ultraviolet-curing acrylate resin

A synthesis method, acrylate technology, applied in the direction of coating, etc., can solve the problems of high energy consumption, long synthesis steps of UV curing coatings, etc., and achieve the effect of simple synthesis, low cost and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

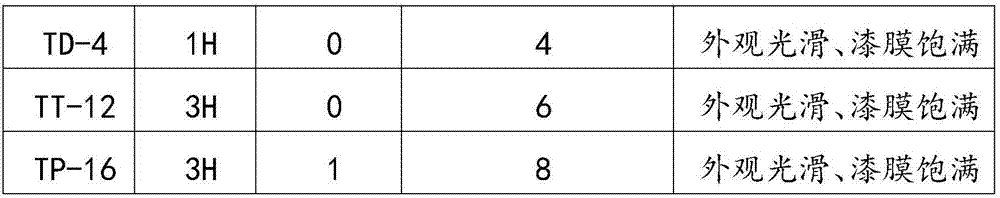

Examples

Embodiment 1

[0019] Example 1 This example discloses the preparation of a UV-curable acrylate resin ED-4 with a hyperbranched structure

[0020] The raw material ethylenediamine (30g) was added into the reaction flask, and then 1,6-hexanediol diacrylate (460g), sodium methoxide (0.5g), and hydroquinone (0.5g) were added. After reacting at 70° C. for about 6 hours, the reaction was stopped, and after the polymerization inhibitor was washed away with 5% NaOH aqueous solution, 483 g of light yellow transparent liquid was obtained.

Embodiment 2

[0021] Example 2 This example discloses the preparation of a UV-curable acrylate resin ET-8 with a hyperbranched structure

[0022] The raw material ethylenediamine (30 g) was added into the reaction flask, and then trimethylolpropane triacrylate (TMPTA) (600 g), sodium methoxide (0.5 g), and hydroquinone (0.5 g) were added. After reacting at 70° C. for about 7 hours, the reaction was stopped, and after the polymerization inhibitor was washed away with 5% NaOH aqueous solution, 622 g of light yellow transparent liquid was obtained.

Embodiment 3

[0023] Example 3 This example discloses the preparation of a UV-curable acrylate resin EP-12 with a hyperbranched structure

[0024] The raw material ethylenediamine (30g) was added into the reaction flask, and then pentaerythritol tetraacrylate (PET4A) (710g), sodium methoxide (0.5g), and hydroquinone (0.5g) were added. After reacting at 80° C. for about 8 hours, the reaction was stopped, and after the polymerization inhibitor was washed away with 5% NaOH aqueous solution, 728 g of light yellow transparent liquid was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com