Electrified railway cantilever supporting device

A technology for electrified railways and support devices, which is applied to overhead lines and other directions, can solve the problems of difficult overall movement, stuck connecting ends of clues and wrist-arm support devices, and deflection of wrist-arm support devices. Good effect, strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

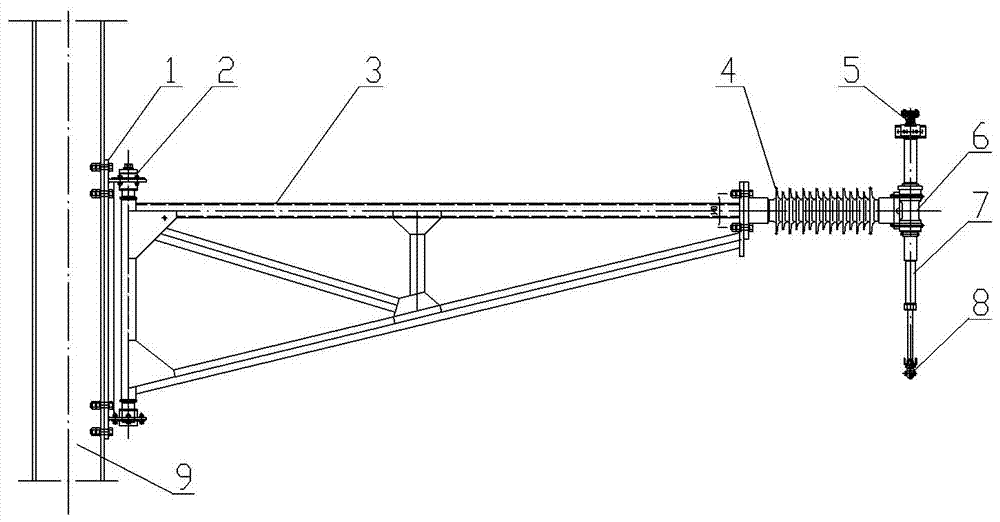

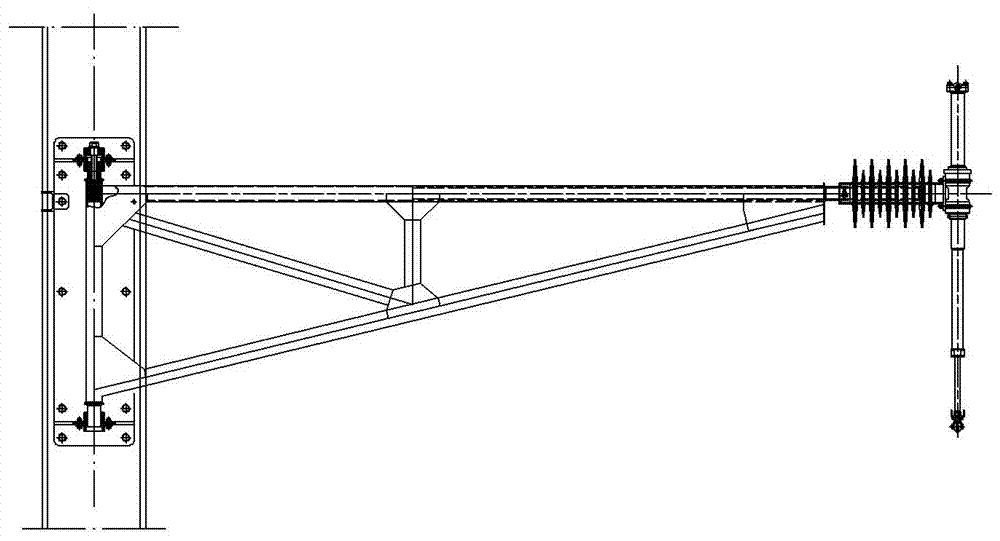

[0027] The present invention relates to an electrified railway arm supporting device, comprising an arm fixed base 1, an arm rotating shaft 2, a triangular truss 3, an arm supporting insulator 4, a positioning rotating shaft 6 and a positioning riser 7.

[0028] The wrist arm fixed base 1 is fixed on the side wall of the pillar 9 by bolts, and the connection method is connected by a reserved hole. The reserved hole adopts three rows of screw holes for step-by-step adjustment, and the channel-type stepless adjustable base can also be used. The connection method is simple and reliable , easy to adjust. A vertical arm rotation shaft 2 is installed on the wrist arm fixed base 1, and the upper and lower ends of the wrist arm rotation shaft 2 are installed on the wrist arm fixed base 1 by the wrist arm rotation shaft shaft seat provided on the wrist arm fixed base 1. The wrist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com