Polishing liquid performance continuous real-time adjusting and control device

A real-time control and polishing liquid technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the temperature control speed and reliability constraints of the mixed liquid, the continuous real-time supply of the mixed liquid is difficult to achieve, and the solution mixing chamber The problem of large chamber volume, etc., can ensure the controllability and stability, reduce the volume and operating noise, and avoid accidental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

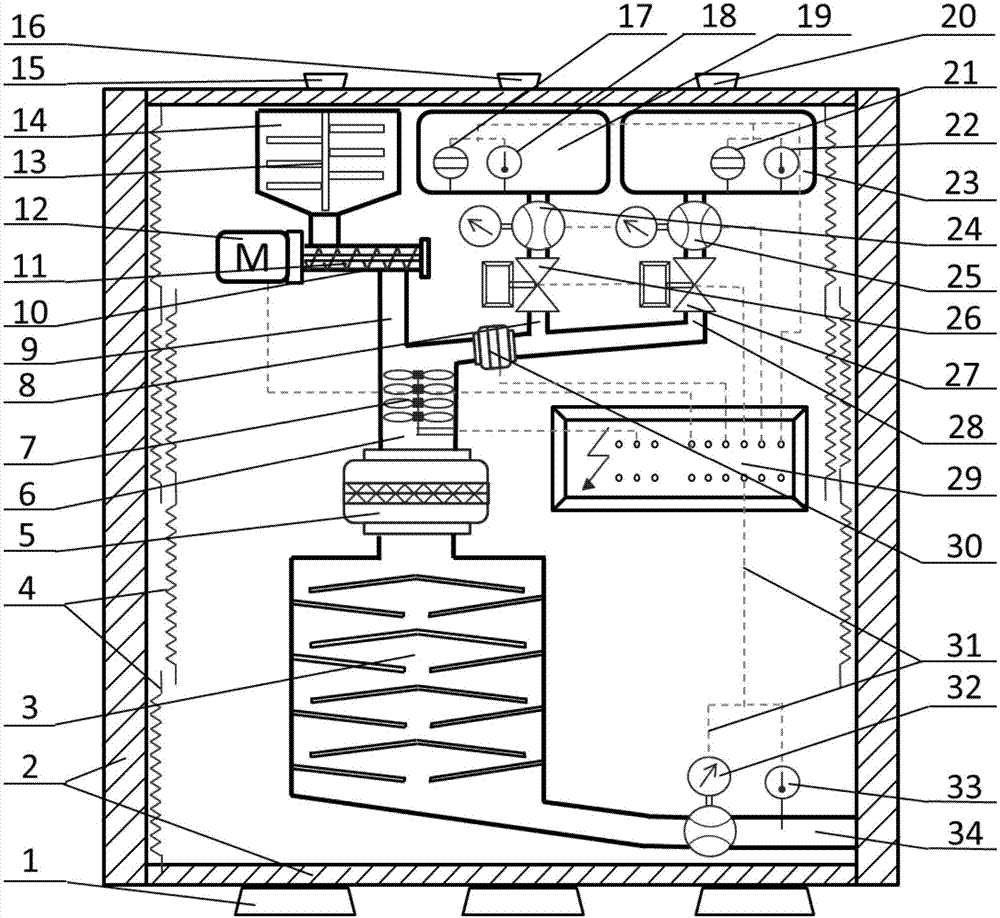

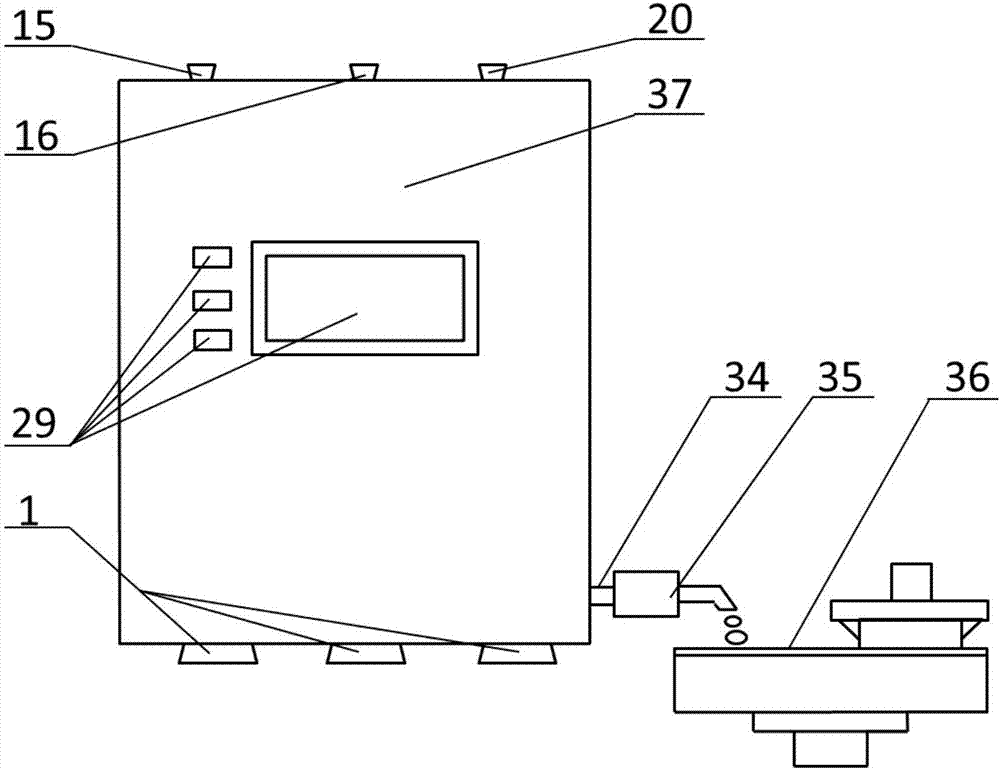

[0024] The specific implementation manners of the present invention will be described in detail below in combination with technical solutions and accompanying drawings. Such as Figure 1-2 As shown, a continuous real-time control device for polishing fluid performance, including a powder component storage and delivery unit, a liquid component storage and delivery unit, a component mixing output unit, a control and an accessory unit; the powder component storage and delivery unit It is located side by side with the liquid component storage and delivery unit on the upper part of the whole device, the component mixing output unit is located under the powder component storage and delivery unit and the liquid component storage and delivery unit, and the control and accessory unit is located on the periphery of the whole device;

[0025] The powder component storage and conveying unit includes a feed inlet A 15, a powder storage tank 14, a powder stirring paddle 13, a precision spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com