Device and method for the finishing machining of an internal face of a workpiece

An inner surface, finishing technology, applied in the field of equipment and methods for finishing the inner surface of a workpiece, can solve the problems of limited thread length, limited oscillation angle of tool holder, etc., to achieve simplified machining, fast and simple tools replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

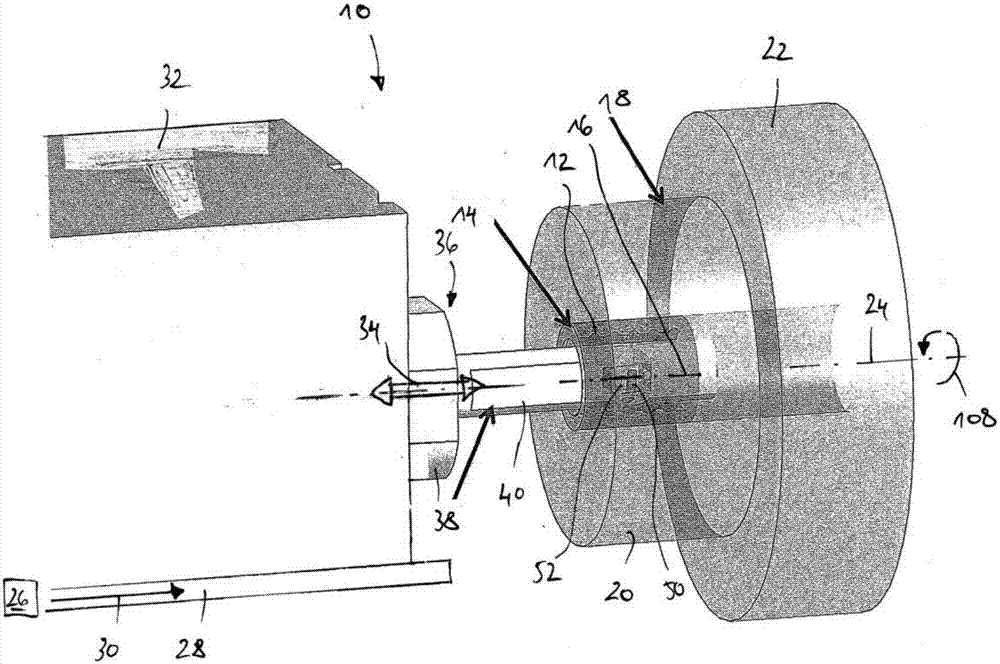

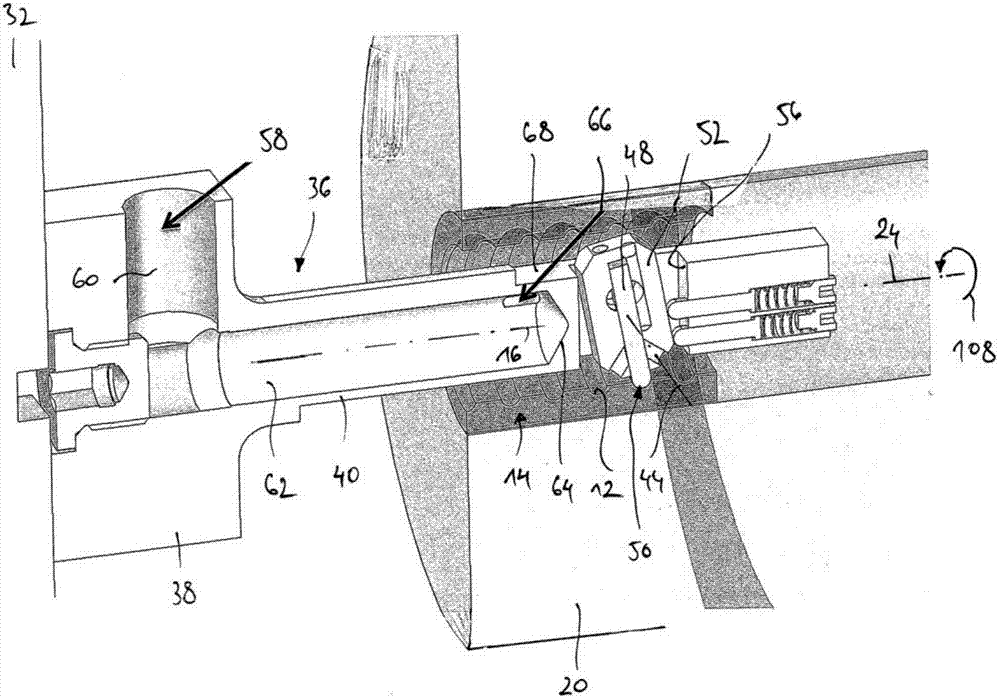

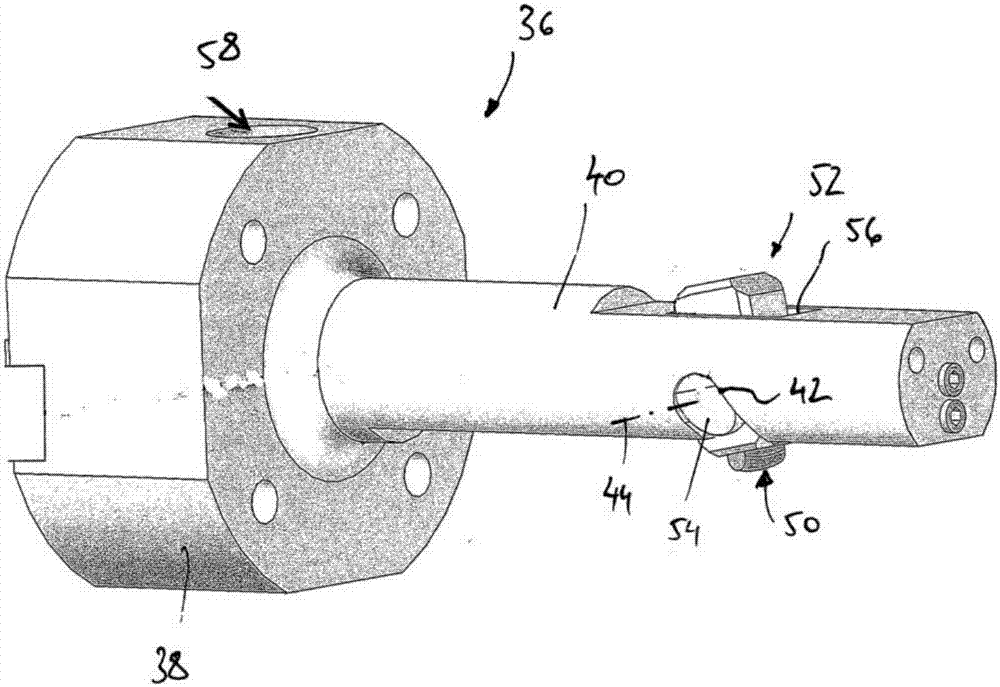

[0033] figure 1 An embodiment of an apparatus 10 for finishing an interior surface 12 of a workpiece 14 is shown.

[0034] The inner surface 12 is in particular the raceway of the ball screw drive. The inner surface 12 is part circular or arcuate in profile. The inner surface 12 extends in a threaded form (helical form) along at least a portion of the length of the workpiece 14 measured parallel to the workpiece axis 16 .

[0035] The device 10 comprises a workpiece holder 18 which can be designed, for example, as a chuck 20 . The workpiece holder 18 is connected to a rotary drive 22 by means of which the workpiece holder 18 and the workpiece 14 are driven rotatably about an axis of rotation 24 .

[0036] The device 10 also comprises a linear drive 26 for driving the slide 28 in a direction parallel to the axis of rotation 24 , for example in a direction 30 in the direction of the workpiece holder 18 or in the opposite direction.

[0037]The slide 28 serves to fix an oscil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com