Device and method for removing CO2 from power plant flue gas by utilizing non-dehydrated flue gas desulfurization gypsum

A desulfurized gypsum, non-dehydrated technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., to achieve the effects of avoiding waste of resources, improving production efficiency, and reducing equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

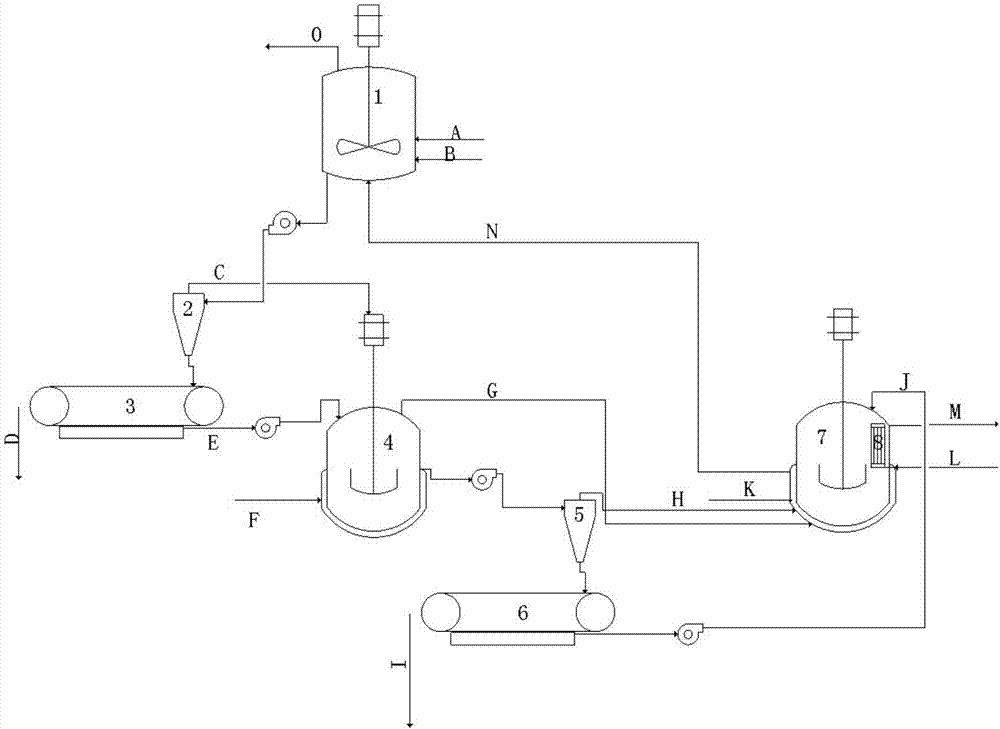

[0041] Such as figure 1 As shown, an undehydrated desulfurized gypsum is used to remove CO from power plant flue gas 2 The device comprises a high-gravity rotary packed bed 1, a first reactor 4 and a second reactor 7; the input end of the high-gravity rotary packed bed 1 is fed with desulfurized gypsum, ammonia water and CO containing 2 The power plant flue gas, the output end is connected to the first reactor; the input end of the first reactor 4 is fed into the slurry for preparing desulfurizing agent, and the output end is connected to the second reactor; the input end of the second reactor 7 It is connected with the ammonia station of the power plant, and the output end is connected with the high-gravity rotating packed bed.

[0042] More specifically, a first hydrocyclone 2 and a first vacuum belt 3 are also provided between the high-gravity rotating packed bed 1 and the first reactor 4, and the output end of the high-gravity rotating packed bed 1 is connected to the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com