Processing method for dealuminzation of salted jellyfish

A processing method and a technology of dealumination, applied in food science and other directions, can solve the problems of excessive aluminum residues in jellyfish, endangering human health, memory loss, etc., and achieve the effects of not affecting physical health, prolonging fresh-keeping period, and reducing aluminum residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

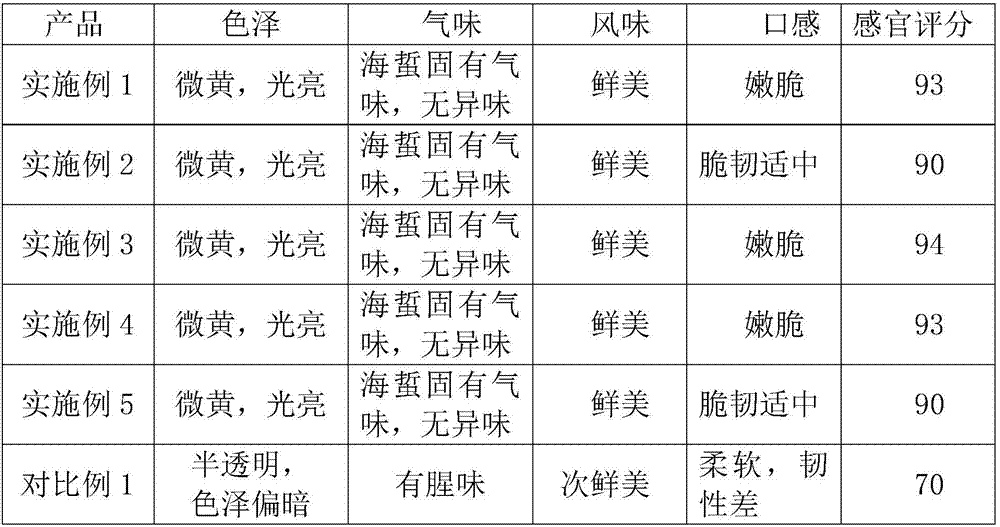

Examples

Embodiment 1

[0031] 1) Raw material pretreatment: take fresh jellyfish, wash the jellyfish skin, separate the scalp, cut the neck, slice the pier, scrape the red coat, remove the stings, then wash it with water and set aside;

[0032] 2) Shred: the pretreated fresh jellyfish is automatically cut into silk with a length of 6 cm and a width of 0.7 cm with a jellyfish shredder;

[0033] 3) salt alum treatment: the shredded jellyfish was put into the salt alum pool for 6 days, and in the salt alum pool, the weight ratio of jellyfish, salt, and alum was 104:13:0.1;

[0034] 4) Dilute: soak in water for 11 hours;

[0035] 5) Dealumination: add Chinese medicine liquid 8 times the weight of jellyfish, and keep the temperature of the Chinese medicine liquid at 35°C for 30 minutes, then rinse with water at 35°C;

[0036] 6) Blanching: blanching the rinsed jellyfish at 85°C for 9 seconds;

[0037] 7) Cooling: Cool the blanched jellyfish in water at 3°C for 130 seconds;

[0038] 8) Pack into bags...

Embodiment 2

[0046] 1) Raw material pretreatment: take fresh jellyfish, wash the jellyfish skin, separate the scalp, cut the neck, slice the pier, scrape the red coat, remove the stings, then wash it with water and set aside;

[0047] 2) Shred: the pretreated fresh jellyfish is automatically cut into silk with a length of 6 cm and a width of 0.7 cm with a jellyfish shredder;

[0048] 3) salt alum treatment: the shredded jellyfish was put into the salt alum pool for 6 days, and in the salt alum pool, the weight ratio of jellyfish, salt, and alum was 104:13:0.1;

[0049] 4) Dilute: soak in water for 11 hours;

[0050] 5) Dealumination: add Chinese medicine liquid 9 times the weight of jellyfish, and keep the temperature of the Chinese medicine liquid at 30°C for 35 minutes, then rinse with water at 34°C;

[0051] 6) Blanching: blanching the rinsed jellyfish at 85°C for 9 seconds;

[0052] 7) Cooling: Cool the blanched jellyfish in water at 3°C for 130 seconds;

[0053] 8) Pack into bags...

Embodiment 3

[0061] 1) Raw material pretreatment: take fresh jellyfish, wash the jellyfish skin, separate the scalp, cut the neck, slice the pier, scrape the red coat, remove the stings, then wash it with water and set aside;

[0062] 2) Shred: the pretreated fresh jellyfish is automatically cut into silk with a length of 6 cm and a width of 0.7 cm with a jellyfish shredder;

[0063] 3) salt alum treatment: the shredded jellyfish was put into the salt alum pool for 6 days, and in the salt alum pool, the weight ratio of jellyfish, salt, and alum was 104:13:0.1;

[0064] 4) Dilute: soak in water for 11 hours;

[0065] 5) Dealumination: add Chinese medicine liquid 10 times the weight of jellyfish, and keep the temperature of the Chinese medicine liquid at 40°C for 40 minutes, then rinse with water at 33°C;

[0066] 6) Blanching: blanching the rinsed jellyfish at 85°C for 9 seconds;

[0067] 7) Cooling: Cool the blanched jellyfish in water at 3°C for 130 seconds;

[0068] 8) Pack into bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com