A thermal shock system and a thermal shock machine provided with the system

A technology of cold and heat shock and impact machine, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high temperature and low temperature for a long time, high power consumption of mechanical refrigeration, large energy consumption, etc., and achieve rapid and stable temperature rise and fall , High precision temperature control, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

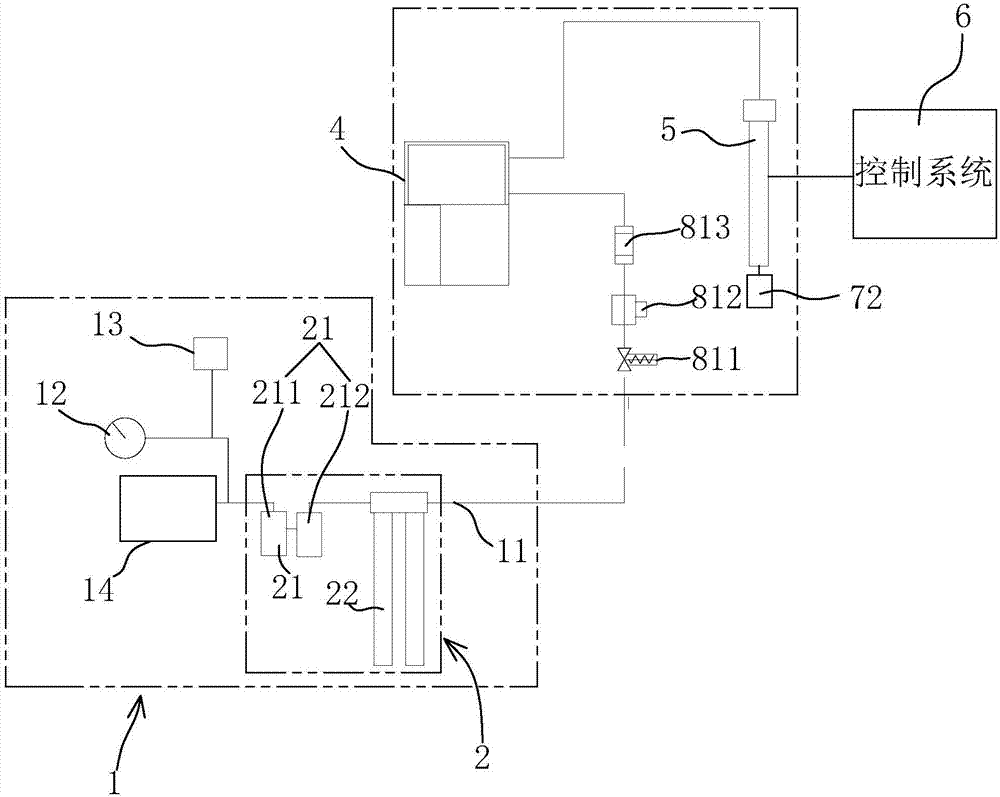

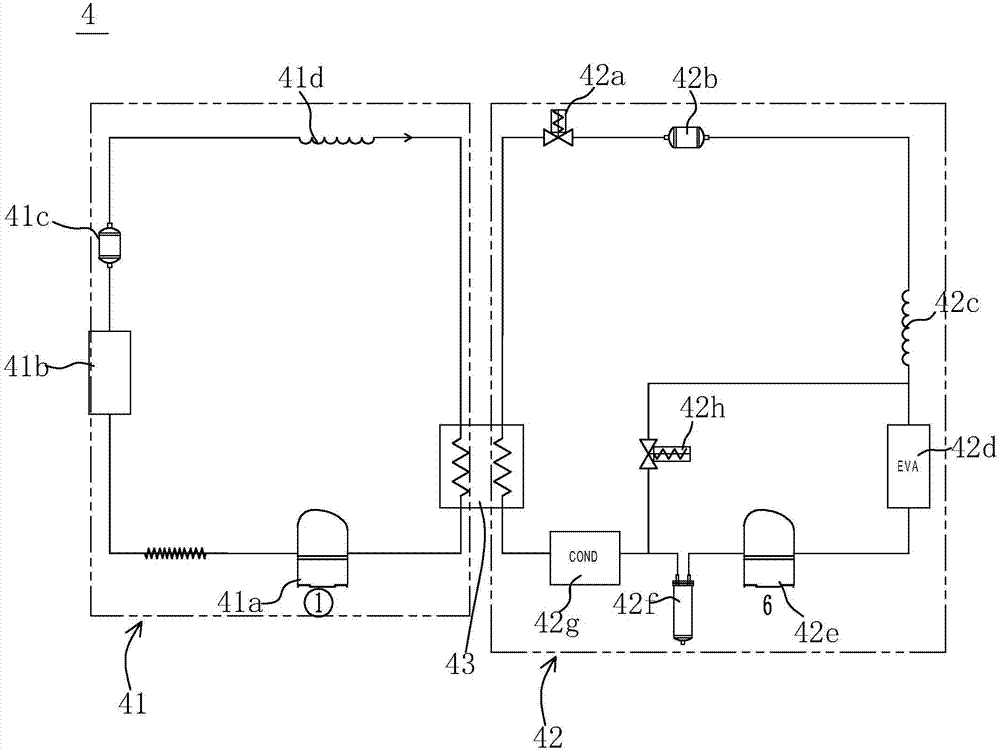

[0044] Please refer to the attached figure 1 , a cold and heat impact system, comprising an air intake system 1, the compressed air pipeline 11 of the intake system 1 is fed with compressed air 14 with a pressure of 70psi-130psi high pressure, preferably air with a pressure of 90psi-110psi, and compressed air The pipeline 11 is connected with an air treatment system 2. The air treatment system 2 includes an oil dust filter 21 and a dry air generator 22 connected in sequence. The oil dust filter 21 includes a dust filter 211 and an oil filter 212, respectively. The oil and dust in the air are filtered to ensure the removal of impurities in the air, and a dry air generator 22 is further installed. The dry air generator 22 is used to remove water droplets in the air, so that the compressed air 14 is fully dried.

[0045] Based on the above settings, an air pressure gauge 12 and an air pressure switch 13 are connected to the air inlet of the compressed air pipeline 11. The air pre...

Embodiment 2

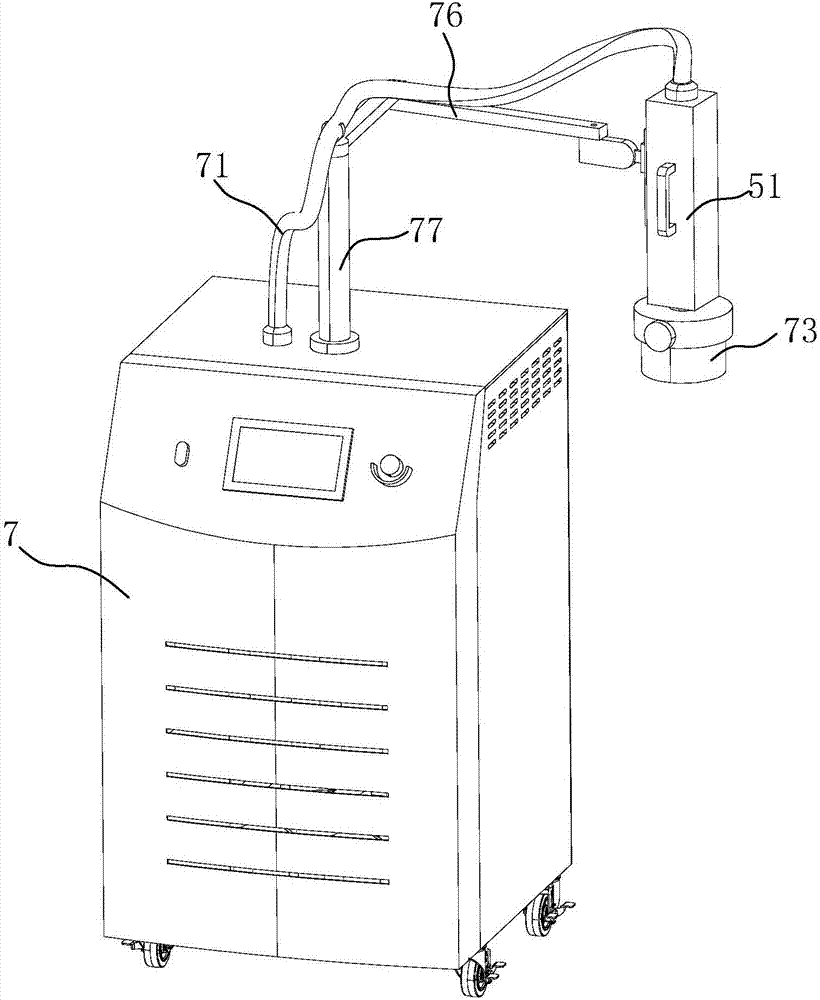

[0053] Please refer to the attached image 3 combined with the attached Figure 6 , a cold and hot impact machine, comprising an impact machine housing 7, an impact machine system is installed inside the impact machine housing 7, the impact machine system includes an air intake system 1, the compressed air pipeline 11 of the air intake system 1 and the compressed air Air 14 pipelines are connected, and are used to pass into 70psi~130psi high-pressure compressed air 14, preferably 90psi~110psi pressure air, compressed air pipeline 11 is arranged on the rear side of impact machine housing 7, in impact machine housing 7 The air pressure gauge 12 and the air pressure switch 13 are connected in sequence with the air inlet of the compressed air pipeline 11, the air pressure gauge 12 is used to detect the air pressure of the compressed air 14, and the air pressure switch 13 is used for high pressure The opening and closing of the compressed air 14 can intuitively see the pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com