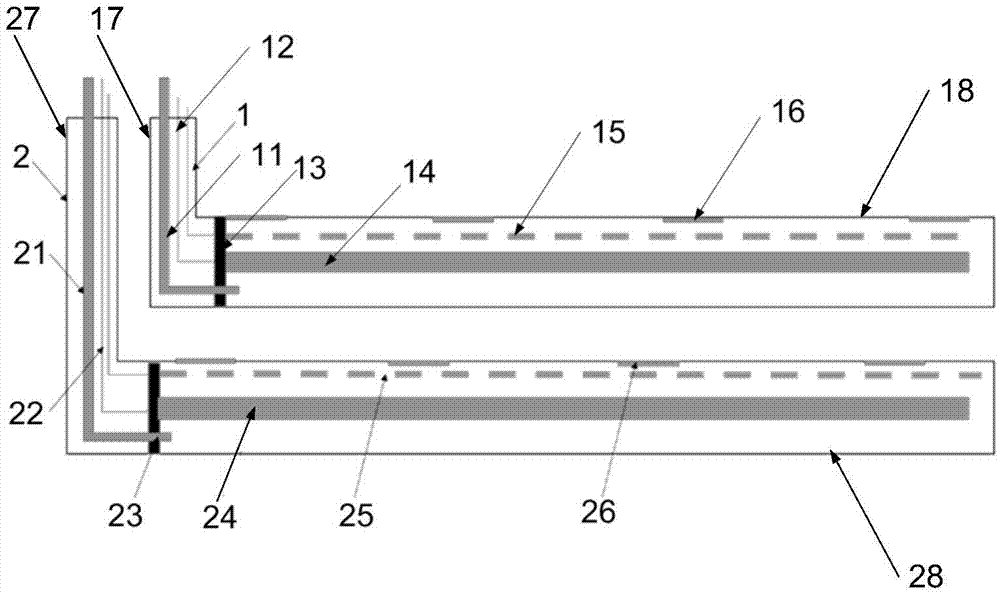

Preheating device and method for heavy oil reservoir

A technology for heavy oil reservoirs and preheating devices, which is applied in earthwork drilling, production fluids, boreholes/well components, etc., and can solve the problems of restricting SAGD production of medium-deep heavy oil reservoirs and circulation pre-heating of medium-deep heavy oil reservoirs. Problems such as difficult realization of heat and limited application range, etc., to achieve uniform, effective and high-speed formation of heat communication, avoiding the output of steam and heat, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0090] An oil reservoir in Xinjiang has a depth of 200m, an oil layer thickness of 10m, an oil layer permeability of 2000md, and an oil layer temperature of 18°C; at the reservoir temperature, the degassed viscosity of crude oil is 500,000mPa.s, the oil saturation is 75%, and the oil layer dip angle is 6°. Circular preheating injection-production parameters: bottom hole dryness 75%, maximum steam injection pressure 2.0MPa. Electric heater parameters: operating temperature 250 ℃, heating power 150KW. Nanofluid parameters: SIC nanoparticles have a diameter of 13nm and a volume concentration of 1.5%.

[0091] 1) Screening is carried out according to the characteristics of the reservoir, which meets the screening criteria of steam-assisted gravity drainage: reservoir depth 4m; oil layer plane permeability > 500 md, oil layer vertical permeability > 200md; crude oil viscosity > 2000mPa. s; oil saturation > 50%; net-to-gross ratio > 0.7;

[0092] 2) The horizontal section of th...

example 2

[0098] In actual reservoir applications, a comparison was made between steam cycle preheating and nanofluid-assisted electric heating preheating start-up methods. Basic reservoir parameters: porosity 30%, oil saturation 75%, permeability 2000md, oil layer thickness 10m, crude oil degassing viscosity at reservoir temperature 500000mPa.s. Circular preheating injection-production parameters: bottom hole dryness 75%, maximum steam injection pressure 4.0MPa. Electric heater parameters: operating temperature 250 ℃, heating power 200KW. Nanofluid parameters: Al2O3 nanoparticles have a diameter of 10nm and a volume concentration of 2%.

[0099] Basic parameters of the well pattern: the length of the horizontal section is 200m, and the distance between the upper and lower horizontal wells is 5m.

[0100] The effect and efficiency of preheating in two ways are compared:

[0101] 1) Conventional cycle preheating for 200 days, heating the formation between horizontal wells to 100°C, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com