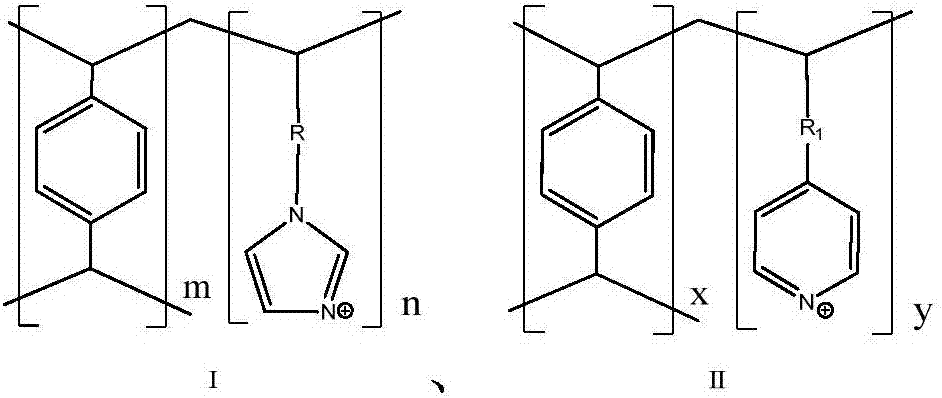

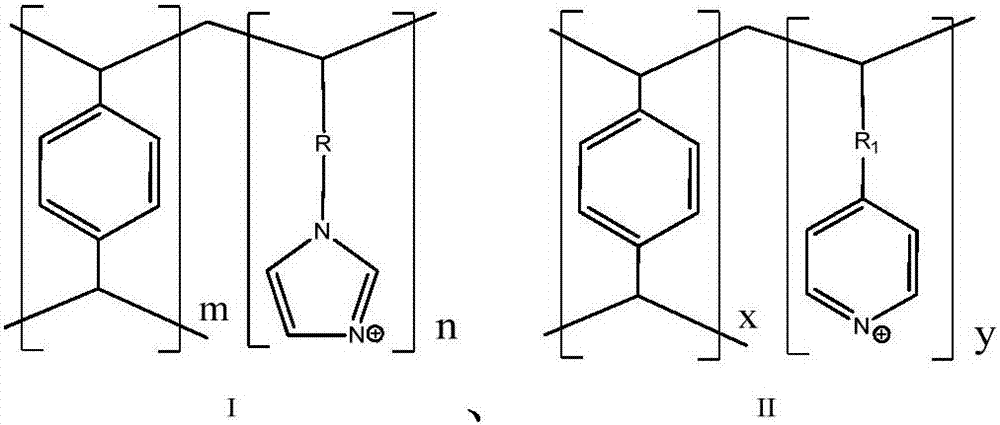

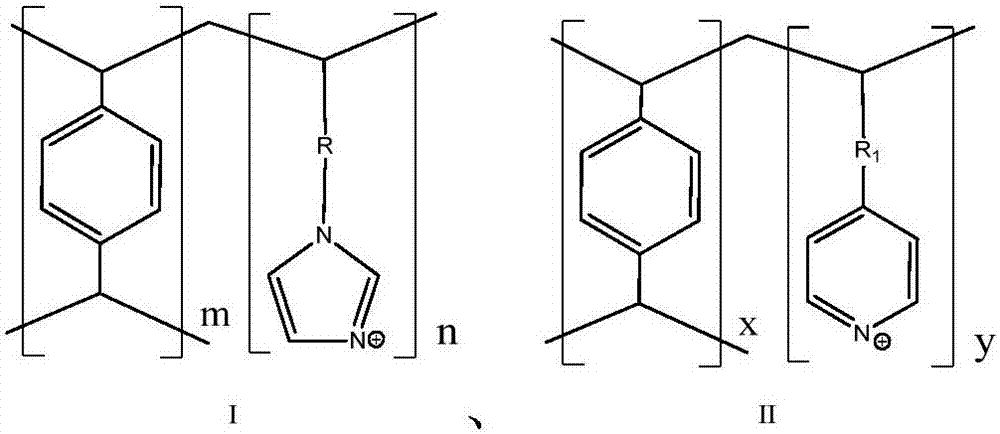

An acidic polymerized ionic liquid, and a preparing method and applications thereof

A technique for polymerizing ionic liquids and acids, which is applied in chemical instruments and methods, production of liquid hydrocarbon mixtures, organic compound/hydride/coordination complex catalysts, etc. It can solve problems such as potential safety hazards, and achieve moderate catalytic reaction temperature, Easy regeneration and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides a method for preparing an acidic polymeric ionic liquid, comprising the following steps:

[0030] Add the monomer, cross-linking agent, initiator and the first organic solvent into the reactor, stir and mix for 2-5 hours, react at 100-200°C for 24-48 hours, cool and dry to obtain the polymerized ionic liquid carrier, wherein , the polymerized ionic liquid monomer is an aromatic heterocyclic olefin, the addition amount of the initiator is 0.3% to 5% of the molar weight of the polymerized ionic liquid monomer, and the added amount of the crosslinking agent is 0.2% of the molar weight of the polymerized ionic liquid monomer. ~5 times, the addition amount of solvent is 5~25 times of the molar weight of polymerized ionic liquid monomer;

[0031] The polymeric ionic liquid carrier and the quaternary amination reagent are dissolved in a second organic solvent at a molar ratio of 1:0.5 to 1:1.5, and the amount of the second ...

Embodiment 1

[0038] Polymerized ionic liquid carrier was synthesized with ethyl acetate as solvent, ammonium persulfate as initiator, divinylbenzene as crosslinking agent and vinylimidazole as monomer. Synthetic process: Add divinylbenzene and 1-vinylimidazole to ethyl acetate at a molar ratio of 1:1, stir and mix in a constant temperature water bath for 2 hours. Then the above mixture was heat-treated with high-pressure solvent in an oven at 100°C for 24 hours, and dried in a vacuum oven at 80°C for 48 hours to obtain the polymerized ionic liquid.

[0039] Add the prepared polymeric ionic liquid to methyl iodide at a molar ratio of 1:1 into absolute ethanol, and stir at room temperature and pressure for 24 hours under dark conditions. After the reaction, filter, wash with ethyl acetate, and dry in a vacuum oven at 80° C. for 48 hours to obtain a quaternized polymeric ionic liquid.

[0040] Add quaternized polymerized ionic liquid, anhydrous aluminum chloride, and copper chloride in a mol...

Embodiment 2

[0042] Polymerized ionic liquid carriers were synthesized with ethyl acetate as solvent, ammonium persulfate as initiator, divinylbenzene as crosslinking agent and vinylpyridine as monomer. Synthetic process: Add divinylbenzene and 1-vinylimidazole to ethyl acetate at a molar ratio of 1:1, stir and mix in a constant temperature water bath for 2 hours. Then the above mixture was heat-treated with high-pressure solvent in an oven at 100°C for 24 hours, and dried in a vacuum oven at 80°C for 48 hours to obtain the polymerized ionic liquid.

[0043] Add the prepared polymeric ionic liquid to methyl iodide at a molar ratio of 1:1 into absolute ethanol, and stir at room temperature and pressure for 24 hours under dark conditions. After the reaction, filter, wash with ethyl acetate, and dry in a vacuum oven at 80° C. for 48 hours to obtain a quaternized polymeric ionic liquid.

[0044] Add quaternized polymerized ionic liquid, anhydrous aluminum chloride, and copper chloride in a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com