Production method of electric fused magnesium oxide spherical crystal structure

A technology of fused magnesia and production method, which is applied in the field of fused magnesia, can solve the problems affecting the flow rate, flow rate and density of the final product, slow flow rate, slow flow rate, etc., to improve the production environment, improve the flow rate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

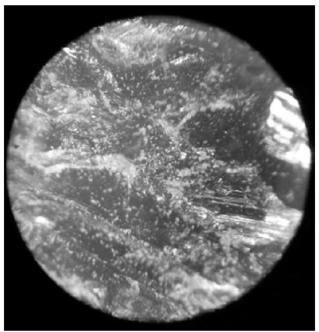

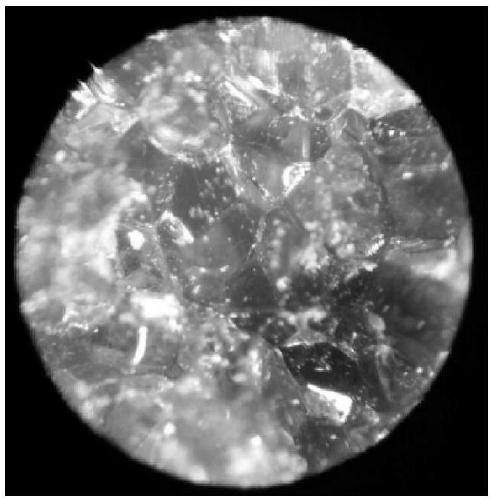

Image

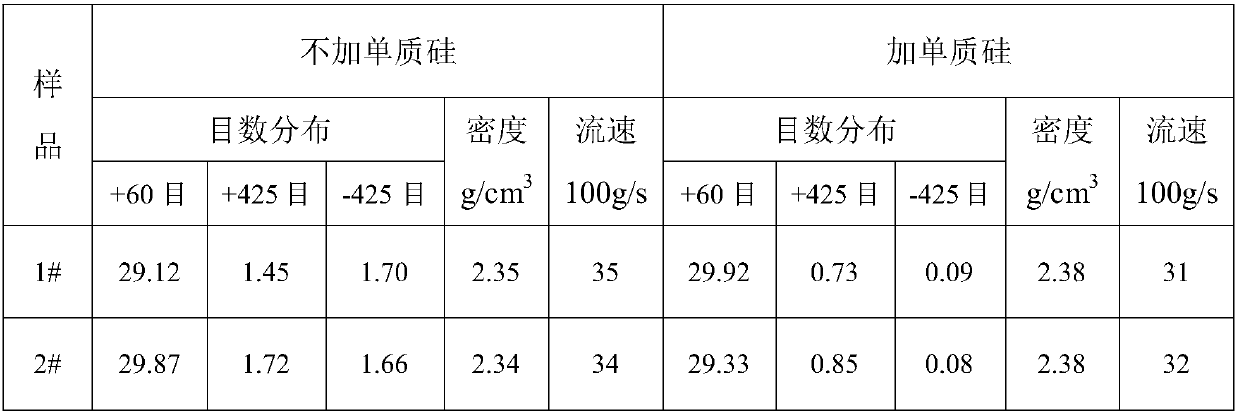

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The production method of electro-fused magnesium oxide spherical crystal structure comprises the following steps:

[0026] Step 1: Select 20 tons of magnesite ore with magnesium oxide content ≥ 46% (wt%) as the raw material of fused magnesium oxide, and crush it in a jaw crusher to make 0mm-10mm blocks for later use.

[0027] Step 2: choose elemental silicon (also called metal silicon) with a content of more than 99% (wt%) and crush it in a jaw crusher to make small pieces between 3 mm and 6 mm.

[0028] Step 3: Weigh 30kg-80kg of the small piece of elemental silicon in Step 2, and set aside.

[0029] Step 4: Prepare a cylinder with a diameter of 1.8m, a height of 2m, and an iron plate thickness of 6mm before production, place the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com