An oil-water separation device and process for oilfield acidizing fracturing fluid

An oil-water separation device, acid fracturing technology, applied in the direction of grease/oily substance/suspton removal device, special compound water treatment, centrifugal separation water/sewage treatment, etc., can solve the problem of large discharge change and difficult flowback liquid Problems such as standard treatment and difficulty in flowback liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

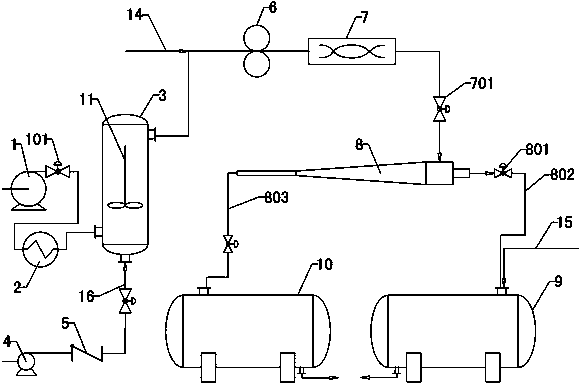

[0028] Refer to attached figure 1 : An oil-water separation device for acidizing and fracturing fluid in an oil field, comprising an acidizing and fracturing flowback fluid delivery pipeline, a heat exchanger 2, a gel breaking device, an emulsion breaking and mixing device, a cyclone separation device, and the outlets of the cyclone separation device are respectively connected The oil storage tank 9 and the sewage tank 10; the acidizing fracturing flowback fluid delivery pipeline is connected to the lower part of the gel breaking device through the heat exchanger 2, the upper part of the gel breaking device is connected to the demulsification mixing device, and the demulsification mixing device is connected to the cyclone The separation device, the overflow port and the underflow port of the cyclone separation device are respectively connected to the oil storage tank 9 and the sewage tank 10 through pipelines.

[0029]The acidizing fracturing flowback fluid delivery pipeline i...

Embodiment 2

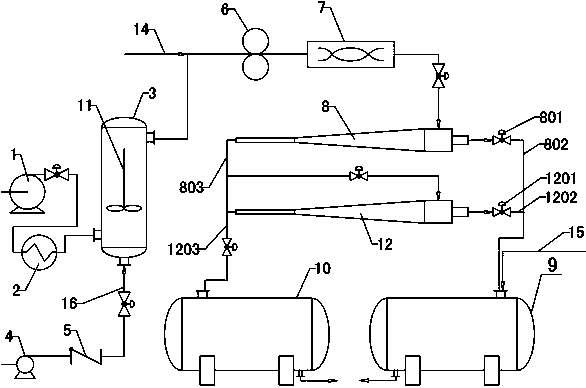

[0040] Refer to attached figure 2 : The cyclone separation device includes a primary cyclone 8 and a secondary cyclone 12, the bottom flow port of the primary cyclone 8 is connected to the inlet of the secondary cyclone 12 and the sewage tank 10 through the primary sewage discharge pipeline 803 respectively , the underflow port of the secondary cyclone 12 is connected to the sewage tank 10 through the secondary sewage discharge pipeline 1203, and the overflow port of the primary cyclone 8 and the overflow port of the secondary cyclone 12 are jointly connected to the oil storage tank 9 , the inlet end of the oil storage tank 9 is also connected to the second demulsifier adding pipe 15 . The overflow port of the primary cyclone 8 and the overflow port of the secondary cyclone 12 are respectively provided with a primary dirty oil discharge pipe 802 and a secondary dirty oil discharge pipe 1202, a primary dirty oil discharge pipe 802 and a secondary dirty oil discharge pipe 1202....

Embodiment 3

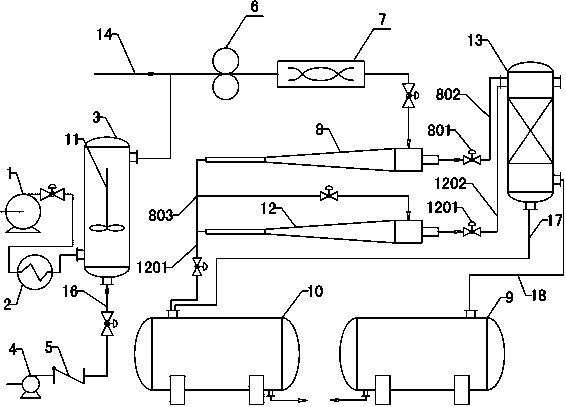

[0043] Refer to attached image 3 : A demulsification tank 13 is provided between the overflow port of the primary cyclone 8 and the overflow port of the secondary cyclone 12 and the oil storage tank 9, and the upper inlet of the demulsification tank 13 is connected to the primary cyclone through a pipeline The overflow port of the device 8 and the overflow port of the secondary cyclone 12, the drain pipe 17 at the bottom of the demulsification tank 13 is connected to the sewage tank 10, and the oil drain pipe 18 at the bottom of the demulsification tank 13 is connected to the oil storage tank 9.

[0044] When the addition of chemical agents is not conducive to the subsequent demulsification and dehydration of crude oil, the present invention adopts two-stage cyclone separation and mechanical demulsification. The acidified fracturing fluid with high oil content is pumped by the pump 1 and delivered to the gel breaking tank 3 through the heat exchanger 2. The heat exchanger 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com