Machining and locating device, machining machine tool and machining method

A positioning device and positioning mechanism technology, applied in metal processing and other directions, can solve the problems of limiting the working size of the processing table, low machine tool processing productivity, and occupying machine tool processing time, etc., to improve stability and reliability, improve overall processing efficiency, and reduce downtime. The effect of taking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

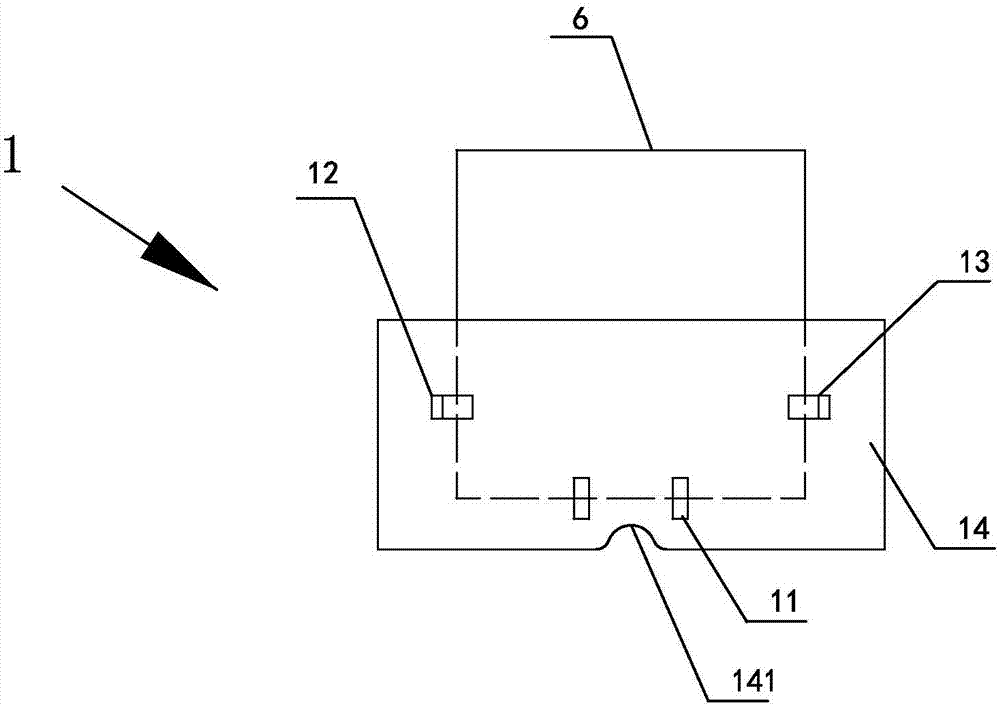

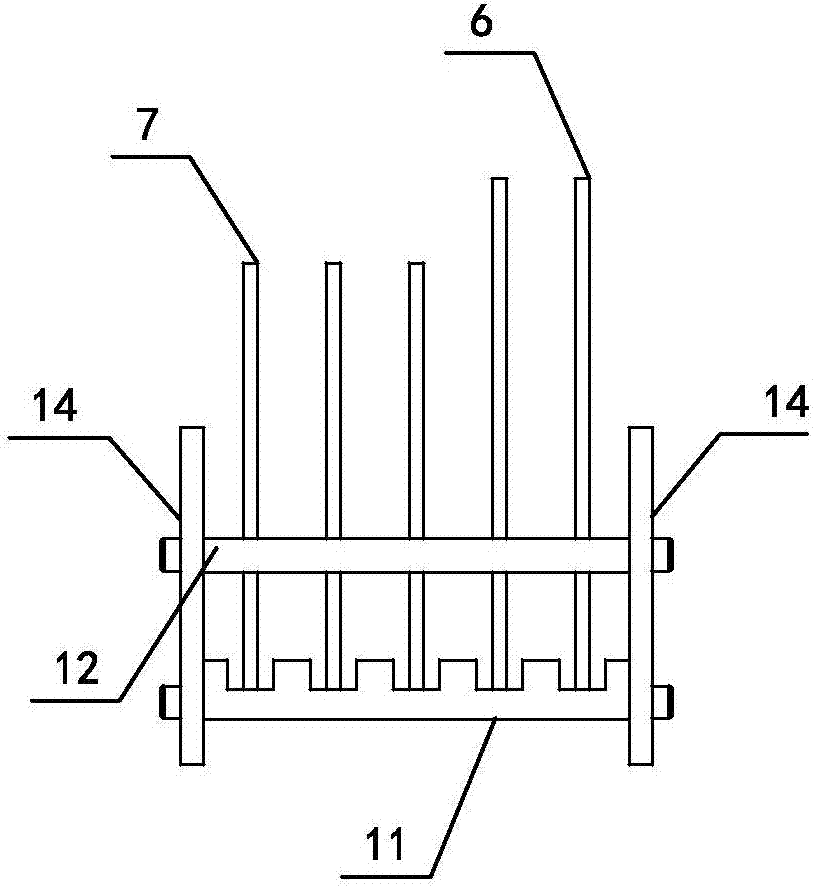

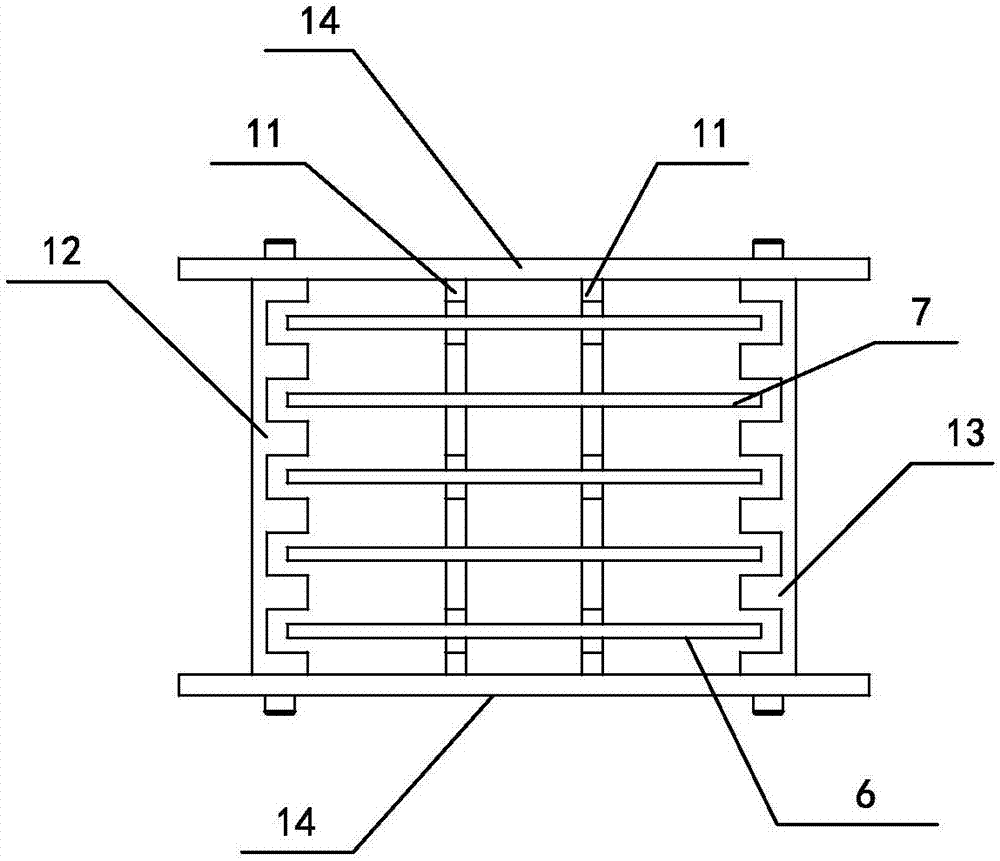

[0044] A preferred embodiment of the present invention provides a processing positioning device, combined with Figure 1-9 As shown, it includes a collection box 1 for loading plates and a positioning platform 2 for carrying the collection box and positioning the plates loaded in the collection box. At least one set of positioning mechanisms is arranged on the positioning platform. The group positioning mechanism corresponds to a collection box, and the positioning mechanism includes: a right positioning rod 22 for positioning the left and right direction of the plate, a floating positioning mechanism 23, and a lower positioning rod 21 for positioning the vertical direction of the plate.

[0045] Described floating positioning mechanism 23 comprises steering guide rod 232, the left positioning rod 231 that is movably connected on the steering guide rod, is used for the guide rod bearing 233 that radially limits the steering guide rod and is connected with the other end of the s...

Embodiment 2

[0053] This embodiment also provides a processing machine tool, combined with Figure 10 and Figure 11 , including the above-mentioned processing and positioning device, and also including a numerical control machine tool 4 and a manipulator 3 for refilling between the processing and positioning device and the numerical control machine tool. Numerical control machine tool can be the numerical control machine tool of any existing known structure, by setting above processing positioning device in front of CNC machine tool workbench or processing table, and the workpiece handling manipulator is set between this processing positioning device and processing table, manipulator can back and forth The processed parts and the parts to be processed are transported and exchanged to form an automatic processing machine tool.

[0054] The workbench on the CNC machine tool can be a mobile workbench or a fixed workbench. A fixture for clamping the workpiece to be processed is installed on ...

Embodiment 3

[0058] The present embodiment provides a kind of processing method, comprises the steps:

[0059] A: After the collection box 1 is placed on the positioning platform 2, the workpiece 6 in the collection box is lifted up to a certain height by the action of the lower positioning rod 21, and then the left positioning rod 231 moves radially to align with the right positioning rod. 22 Accurate positioning of the left and right directions of the workpiece to be processed together;

[0060] B: After the positioning is completed, the manipulator 3 grabs the workpiece to be processed and puts it on the processing table 41 of the CNC machine tool 4. After the processing table completes the clamping of the workpiece to be processed, the processing head 42 of the CNC machine tool processes the workpiece to be processed;

[0061] C: After the processing is completed, the manipulator grabs the processed part 7 and places it in the collection box 1.

[0062] D: The manipulator grabs the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com