Clamping mechanism suitable for clamping flat surface or curved surface

A technology of clamping mechanism and curved surface, which is applied in the direction of clamping, metal processing machinery parts, support, etc., can solve the problems of reducing the efficiency of processing, and achieve the effects of avoiding damage to the workpiece, increasing the contact area, and improving the recovery force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

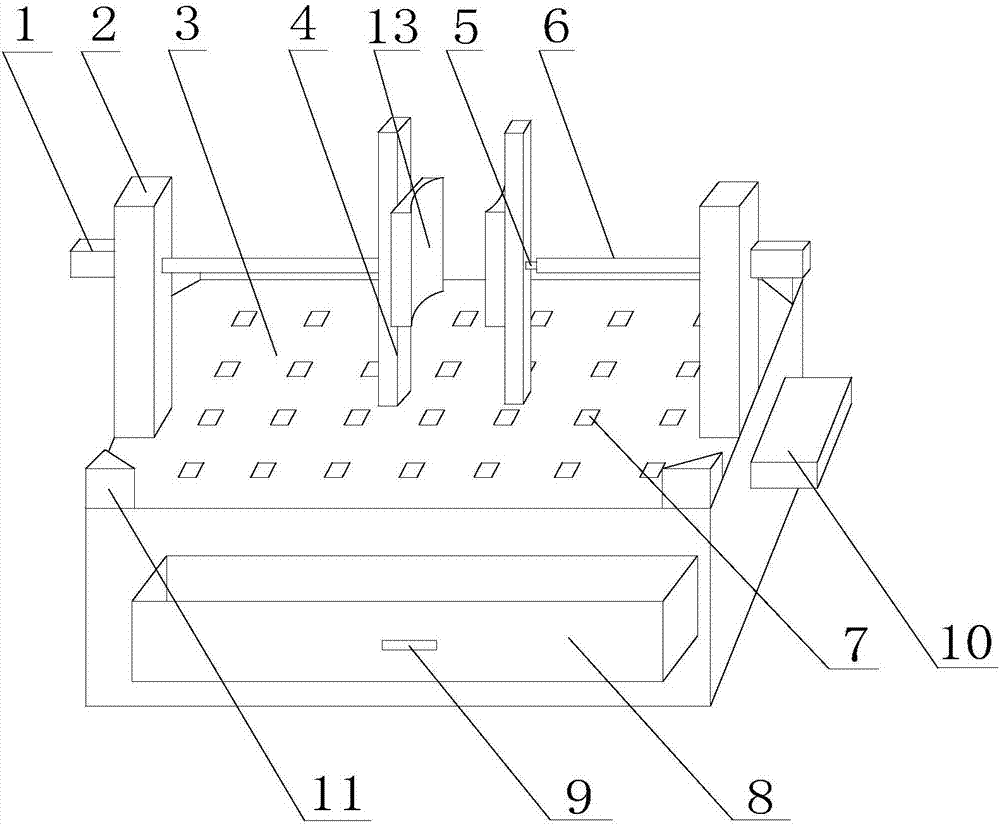

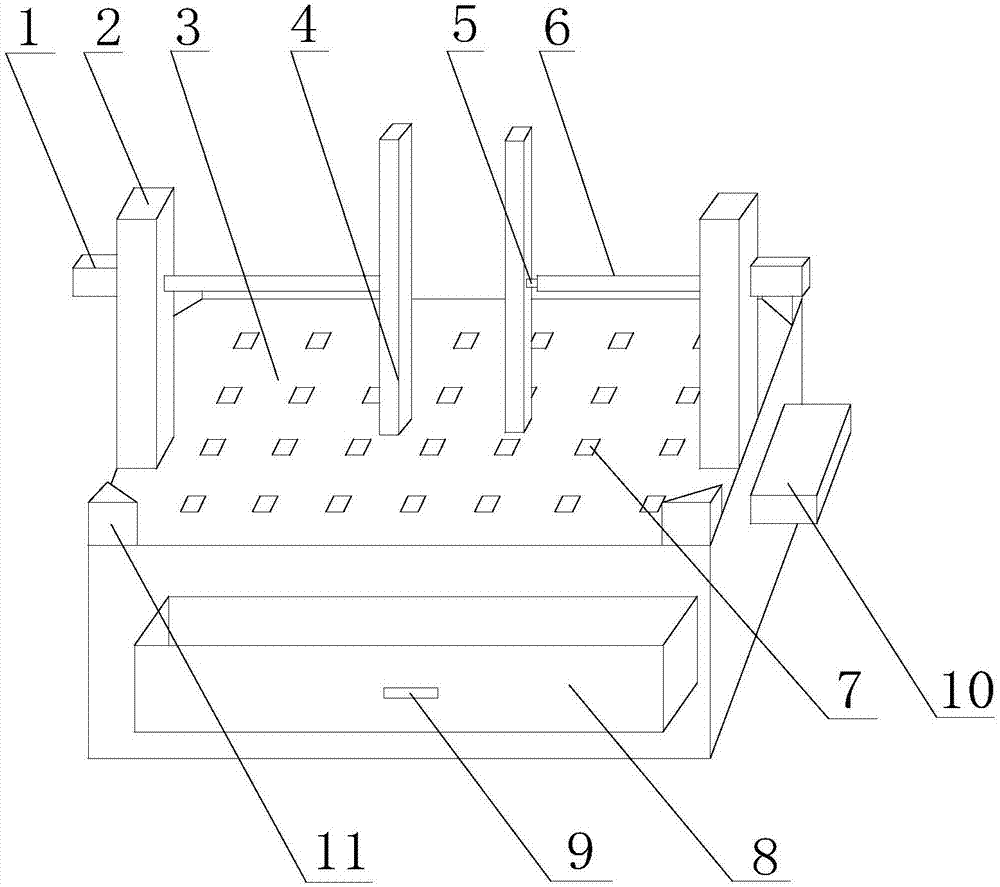

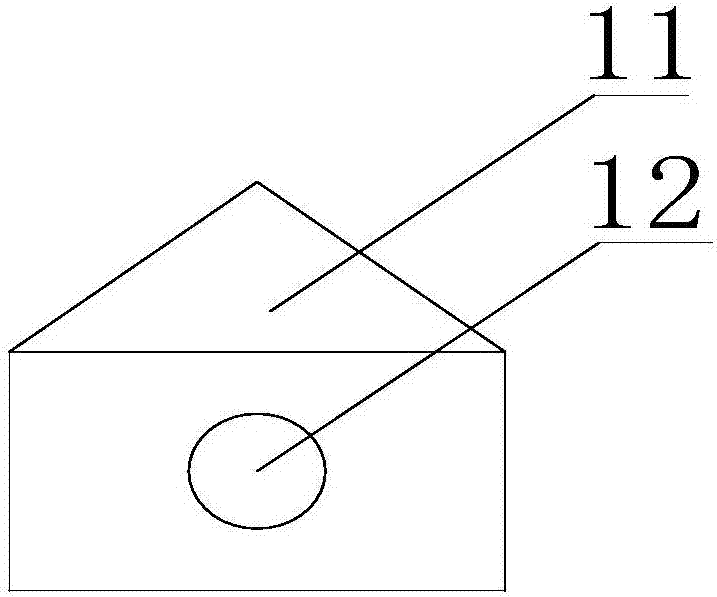

[0028] Such as Figure 1 to Figure 5 As shown, the present invention is applicable to clamping mechanisms for clamping planes or curved surfaces, including a workbench 3 in a rectangular shape, and two support columns 2 are arranged on the top of the workbench 3, and the two support columns 2 are respectively located on the axis of the workbench 3 Both sides, support column 2 is rectangular parallelepiped shape, and length is 60cm, is provided with driving mechanism 1 on the side wall of support column 2, and driving mechanism 1 comprises drive shaft, and drive mechanism 1 is preferably a hydraulic cylinder, and drive shaft is a hydraulic cylinder. The piston rod, the drive shaft crosses on the support column 2, and the end of the drive shaft is provided with a connecting rod 6. Under the action of the driving mechanism 1, the drive shaft can drive the connecting rod 6 to move in the horizontal direction, and one end of the connecting rod 6 Connected with the drive shaft, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com